ECOTILE FLOORING LIMITED

Stand: 17-550

ECOTILE FLOORING LIMITED

Description

No company profile provided.

Categories

No categories provided.

Address

Unit 15North Luton Industrial Estate

Luton

LU4 9DT GB

Website

No website provided.

No products provided.

No videos provided.

No brochures provided.

ELESA (UK) LTD

Stand: 6-66

ELESA (UK) LTD

Description

Established in 1941, Elesa is the international reference for standard machine components destined for the mechanical, machinery and industrial equipment sectors. An excellent combination of technology and design has given rise to a diverse production, thanks to the constant commitment to follow developments in engineering plastics and metal technology.

Categories

Address

26 Moorlands EstateMetheringham

Lincolnshire

LN4 3HX United Kingdom

ELESA expands further into ATEX Compliant Hydraulic Components

ELESA is thrilled to announce their breather cap product extension; providing solutions that redefine the functionality of sealing hydraulic tank fillers, alongside a new ATEX-compliant range, reflecting their commitment to industry-leading safety standards.

New Breather Cap Solutions:

These innovative caps enable smooth air interchange as fluid is channelled to or from the hydraulic reservoir. With Elesa's unique labyrinth geometry, they act as a robust barrier to spillage, perfect for equipment used at variable angles or machines in transit.

ATEX-Compliant Hydraulic Components:

In response to the ATEX regulations, Elesa introduces a series of hydraulic components designed specifically for systems adhering to these stringent guidelines. This range is beneficial to various sectors, including pumps, anti-spark installations, oil and gas, water and sewage, petrochemical plants, mines, and flour mills.

The ATEX range features:

• GN 743.6 Oil Level Indicators: Made with aluminium and featuring ESG safety glass with FKM Viton® sealing ring.

• SFP+a-EX Breather Caps: Incorporating a splash guard and flat dipstick for added functionality.

• TN-EX Equipment Plugs: Crafted in glass-reinforced technopolymer with NBR synthetic sealing rings.

These components, laser engraved and supplied with a comprehensive instruction/safety leaflet, allow users to integrate them into systems in accordance with Health and Safety Requirements under the 94/9/EC ATEX European Directive (explosive atmospheres) for equipment in Group II, category 2GD.

Additional Offerings and Customizations

Elesa continues to provide versatility through a variety of options, including neutral caps, coloured caps, and adjustable threaded fixing. Two innovative designs, SFX and SFX+a, cater to varied industrial applications.

Explore Elesa's Pioneering Solutions

Elesa's new breather caps and ATEX-compliant hydraulic components exemplify the brand's excellence in innovation, safety, and performance. To learn more about these cutting-edge products and other offerings from Elesa, visit www.elesa.com

Award Winning LED Safety Handle

The ADI Design Index 2023 selection presented in Milan the preselection for the Compasso d’Oro (Golden Compass), the prestigious and oldest Italian design award organised by ADI, the Association for Industrial Design. Against the backdrop of the ADI Design Museum’s permanent exhibition in Milan, which was created to preserve and promote the catalogue of projects belonging to the Compasso d'Oro Award’s historical collection (which includes two ELESA products that won the award in 1994), stands this collection which is part of Italy’s national cultural heritage and is recognised by the Ministry of Cultural Heritage as being of exceptional artistic and historical interest.

Every year the Permanent Design Observatory – the ADI institution composed of several panels of experts active throughout Italy and central panels – reviews all Italian design production that will be evaluated by an expert jury and selects products that stand out for their originality and functional and typological innovation, for the production processes employed, for the materials used, and for their formal synthesis. Particular attention is paid to products that demonstrate environmental respect, public and social value, attention to usability, interaction, and Design for all.

Among the 219 products and services selected by the ADI Permanent Observatory, divided into 14 different themed categories, is ELESA's M.2000-SWM, the new handle with monostable switch and LED indicator light that received an award in the "workplace design" category. This new and important accolade confirms the high level of quality of ELESA's new technical solution, which stands out for the character of its distinctive design and its innovative content, already recognised by other prestigious juries such as the LEAP Design Award in the USA in 2022 and the IF Hannover in Germany in 2023.

New ELESA Vacuum Suction Cups for automation

ELESA vacuum components (vacuum suction cups, vacuum cup holders, and related accessories) represent the ideal solution for automatically and safely handling parts with different shapes, sizes, and surfaces (e.g. metal, glass, plastic, ceramic).

The function of these components is based on the presence of a vacuum generator that, by creating a depression inside the vacuum suction cup, allows it to adhere to the surface of the part to be moved. The load grip is maintained as long as there is a vacuum in the system.

Thanks to their versatility, Elesa vacuum suction cups with dimensions ranging from 4 mm to 125 mm, in the classic cup, flat, elliptical, bellows, or multi-bellows shapes, can be used for multiple applications and sectors such as food packaging, in particular in flow pack packaging using plastic films, the electronics sector, the paper converting sector for labels and sheets of paper or cardboard, the automotive sector for handling metal parts or glass windshields, the medical/pharmaceutical sector or for different objects such as ceramic or clay tiles, marble or glass slabs, items made from concrete, wood, and plastic components.

The vacuum suction cups, available in different compounds (oil-proof rubber, silicone, natural or para-natural rubber) are compatible with all products, even those with irregular, rough surfaces or in the presence of oil or liquids.

The presence of grooves and the contoured shape of the vacuum suction cup support surface ensures a strong grip on the load surface, particularly on oiled sheets, glass or marble sheets, facilitating the drainage of any liquids

Latches with push handle

Elesa CSMH latches with compression handle:

- Spindle and protection cap in die-cast zinc alloy

- Packing ring in silicone

- Lock with dustcover

- IP 65 protection class

Polyurethane Wheels

Wheel’s tread, in green soft polyurethane with high thickness, is characterised by good elasticity, high load capacity and resistance to tear, thus guaranteeing absorption of shocks and vibrations, resulting in less force required to push or tow trolleys.

Wireless spindle positioning system: features and functioning

The wireless system, consisting of UC-RF control unit and up to 36 electronic position indicators networked via radio frequency. Efficient manual spindle positioning, easy and quick installation without connecting cables.

Visual flow indicators with flow-meter sensor

The indicator can be mounted in any position. At the passage of the minimum flow rate, the rotor starts to rotate with a speed proportional to the fluid flow. The inductive sensor reads the passage of the two metal clips mounted on the rotor, providing a frequency variation that can be transformed into a reading of the flow rate by connection to a PLC.

Pneumatic Fastening Clamps

Pneumatic fastening clamps are characterized by a high clamping force, reduced size, low consumption of compressed air and reduced weight. These series can be easily completed with standard accessories, without which their correct functioning would not be possible.

No brochures provided.

EMCO

Stand: 17-130

EMCO

Description

Emco is the sole UK distributor for EMCO CNC & Manual Machines, specialising in supplying educational and industrial companies across the UK. With a focus on precision engineering, our innovative solutions empower learning and enhance industrial processes. Committed to excellence, we redefine manufacturing standards through cutting-edge technology and reliable partnerships.

Categories

Address

Unit 4, Hayling Billy Business CentreFurniss Way

Hayling Island

Hampshire

PO11 0ED GB

Emcoturn E25 CNC Lathe

Small workpieces present special challenges.

The EMCOTURN E25 has been designed to meet exactly these challenges. Mostly these are workpieces from the fields of precision engineering, medical technology, electronics, optics or jewellery industry, but also in the automotive sector and in general mechanical engineering where small parts of high quality are needed. A solid and compact machine construction with precision spindle, 12-fold tool turret and tailstock enables the machining of workpieces both from bars and inserts. For the automatic feeding of raw material or blanks a bar loader or a robot can be offered. According to requirements a FANUC or SIEMENS controller

can be used for the built up. Naturally also inclusive of Dialogue programming.

Universal Turn 50

With the new UNIVERSALTURN 50, EMCO sets the next milestone in complete machining of bars and chuck parts. Developed for maximum precision, dynamics and process reliability, the compact high-performance turning centre offers everything that modern manufacturing centres require: powerful drive systems, an integrated Y-axis for extended milling and flexible automation concepts. Whether complex turned and milled parts for mechanical engineering, the automotive industry, medical technology or defence – the UNIVERSALTURN 50 impresses with its outstanding rigidity, intuitive operation and scalable equipment.

Thanks to proven EMCO technologies combined with forward looking developments, users benefit from maximum efficiency, high cost-effectiveness and the highest level of manufacturing quality.

Experience a new dimension in precision and productivity – made by EMCO.

No videos provided.

Universal Turn 50

With the new UNIVERSALTURN 50, EMCO sets the next milestone in complete machining of bar and chuck parts. Developed for maximum precision, dynamics and process reliability, the compact high-performance turning centre offers everything that modern manufacturing centres require: powerful drive systems, an integrated Y-axis for extended milling and flexible automation concepts.

Whether complex turned and milled parts for mechanical engineering, the automotive industry, medical technology or defence – the UNIVERSALTURN 50 impresses with its outstanding rigidity, intuitive operation and scalable equipment.

Thanks to proven EMCO technologies combined with forward looking developments, users benefit from maximum efficiency, high cost-effectiveness and the highest level of manufacturing quality.

Experience a new dimension in precision and productivity –made by EMCO.

MT25 CNC Lathe

The EMCO MAXXTURN 25. The perfect solution for the complete machining of small parts.

Compact, economical with high precision. Suitable for bar parts up to a diameter of 25 mm and chucked parts up to Ø 85 mm. Fitted with a counter spindle, Yaxis and driven tools. The tool turret has space for 12 VDI16 tool holders. The 36 indexing positions mean the number of tools can be increased to 42 cutting edges. The MAXXTURN 25 comes with choice of Siemens or Fanuc control including ShopTurn or ManualGuide conversational programming system.

E25 CNC Lathe

Small workpieces present special challenges. The EMCOTURN E25 has been designed to meet exactly these challenges. Mostly these are workpieces from the fields of precision engineering, medical technology, electronics, optics or jewellery industry but also in the automotive sector and in general mechanical engineering where small parts of high quality are needed.

A solid and compact machine construction with precision spindle, 12-fold tool turret and tailstock enables the machining of workpieces both from bars and inserts. For the automatic feeding of raw material or blanks, a bar loader or a robot can be offered. Available with a choice of FANUC or SIEMENS control.

ENGINEERING MEDIA LTD.

Stand: 18-411

ENGINEERING MEDIA LTD.

Description

Immersive Magazine; Highlighting Machine Tool & Manufacturing Technology with six unique editions per year.

Categories

Address

20-22 Wenlock RoadLondon

N1 7GU GB

No products provided.

No videos provided.

No brochures provided.

ENGINEERING UTILITIES LIMITED

Stand: 6-510

ENGINEERING UTILITIES LIMITED

Description

We have 45 years of knowledge & experience introducing innovation to the metal working industry and beyond; supplying metal surface conditioning consumables & machines along with RESPIRATORY PROTECTION, DEBURRING and EDGE ROUNDING MACHINES, WELD CLEANING, LASER SLAT CLEANING and much much more

Categories

Address

75 Swinnow LaneBramley

Leeds

West Yorkshire

LS13 4TY United Kingdom

No products provided.

No videos provided.

No brochures provided.

EOS

Stand: 17-628

EOS

Description

EOS is the leading technology provider worldwide for industrial 3D printing of metals and plastics. We are pioneers and innovators for integrated solutions in AM and have mastered the interactions between lasers and powder materials. We offer everything you need from a single source: 3D printers, materials, and process parameters.

Categories

Address

The Innovation CentreWarwick Technology Park

Warwick

United Kingdom

CV34 6UW GB

EOS P 770

EOS P 500

EOS P 396

EOS M 400 Series

EOS M 300 Series

EOS M 290

EOS Responsible Manufacturing

Responsible Manufacturing with EOS Industrial 3D Printing.

No brochures provided.

EPICOR SOFTWARE (UK) LTD

Stand: 17-660

EPICOR SOFTWARE (UK) LTD

Description

We’re here for the hard-working businesses that keep the world turning. You’re the companies that make, move, and sell the things we all need. Trust Epicor to help you do business better. Your industry is our industry, and we understand you better than anyone. By working hand-in-hand, we get to know your business almost as well as you do. Our innovative industry solution sets are carefully built

Categories

Address

6 Arlington Square WestBracknell

Berkshire

RG12 1PU United Kingdom

Epicor BisTrack ERP

As the #1 Trusted ERP Provider for the Building Supply Industry, BisTrack offers a comprehensive suite of powerful tools designed to maximise profits, achieve operational excellence, and gain unparalleled visibility across your entire business.

From streamlining inventory management to optimising sales processes, BisTrack's business automation tools empower you to enhance productivity, bolster security, increase margins, and build a more resilient and scalable business.

BisTrack's cloud-first approach, advanced browser capabilities, and 99% customer retention rate demonstrate our unwavering commitment to delivering exceptional value to our users.

With the right tools, your team can better serve customers and foster loyalty. Learn why Epicor is the leader in industry and how we can help you grow and thrive.

Epicor Prophet 21 ERP

Epicor Prophet 21 is an industry-leading cloud-based ERP built with distributors, for distributors. From procurement to shipping and accounts payable, Prophet 21 helps distributors seamlessly connect to a complex supply chain to increase visibility, automate workflows, anticipate issues, and adjust strategies in real-time. We build a lot of our features and enhancements based on customer feedback, ensuring customers remain the driving force in everything we do. Unlike alternative solutions, Prophet 21 is ready to use, out of the box, with no customisations needed.

Epicor Kinetic ERP

Epicor Kinetic ERP is a global, enterprise resource planning solution purpose-built for manufacturers. Designed with deep industry expertise, it delivers end-to-end capabilities for discrete, make-to-order, and mixed-mode manufacturing, helping businesses streamline operations, boost productivity, and accelerate growth.

Kinetic combines advanced planning and scheduling (APS), manufacturing execution systems (MES), and configure-price-quote (CPQ) tools with embedded automation, AI-driven insights, and no/low-code customisation for agility and scalability. Its composable architecture and open APIs enable seamless integration with third-party applications, while flexible deployment options, cloud, on-premises, or hybrid support evolving business needs. By reducing complexity and enhancing real-time visibility across finance, supply chain, and production workflows, Epicor Kinetic empowers manufacturers to innovate, optimise processes, and compete effectively in a dynamic global marketplace.

No brochures provided.

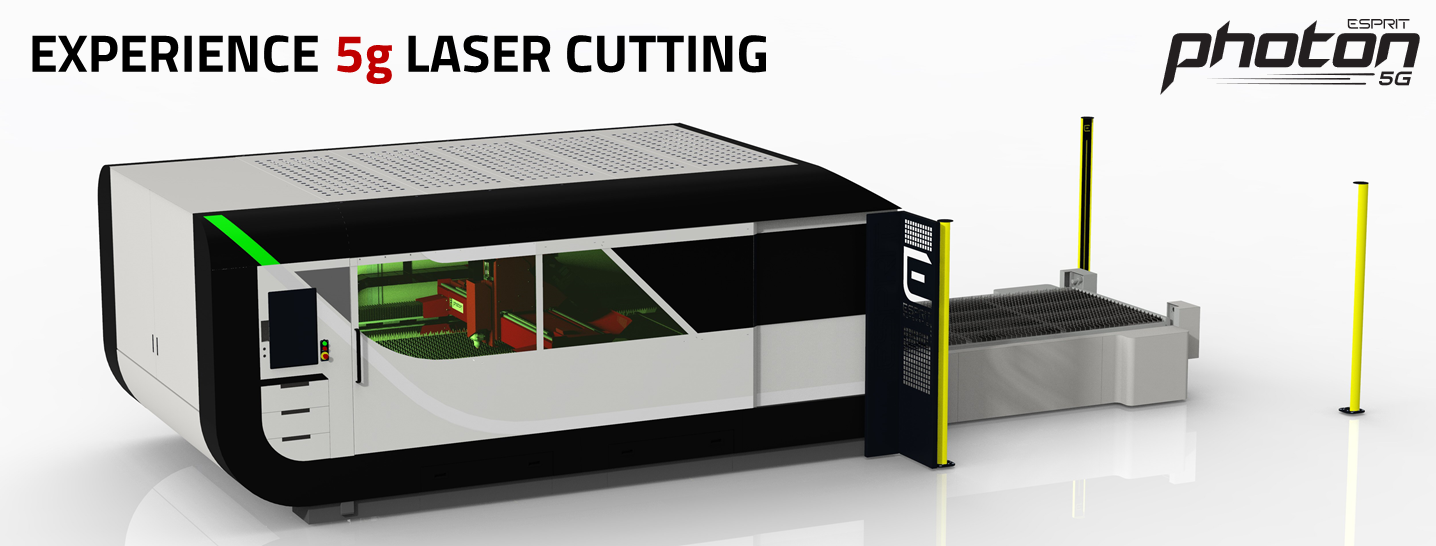

ESPRIT AUTOMATION LIMITED

Stand: 6-660

ESPRIT AUTOMATION LIMITED

Description

UK manufacturers of CNC laser and plasma systems since 1986. We excel in affordable entry-level lasers and heavy industrial plasma machines, offering a wide range of British-built solutions to manufacturers across all sectors. With 40 years of heritage, we provide performance, reliability, and expert local support.

Categories

Address

Placketts MillChurch Drive

Nottingham

Nottinghamshire

NG10 5EE GB

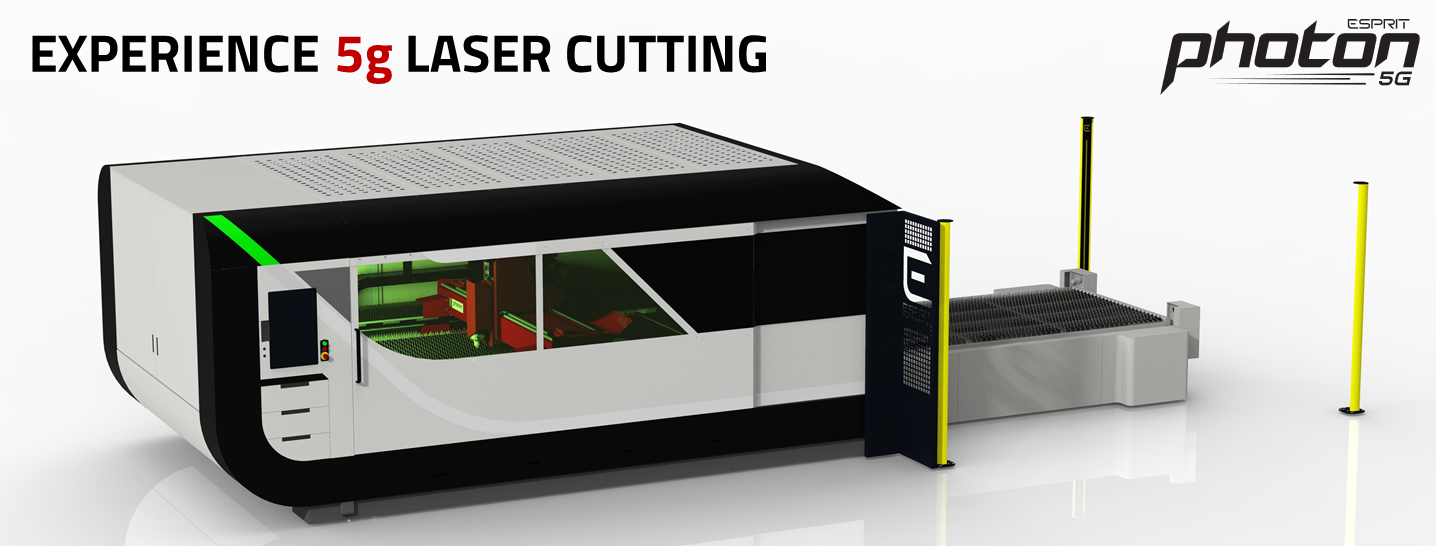

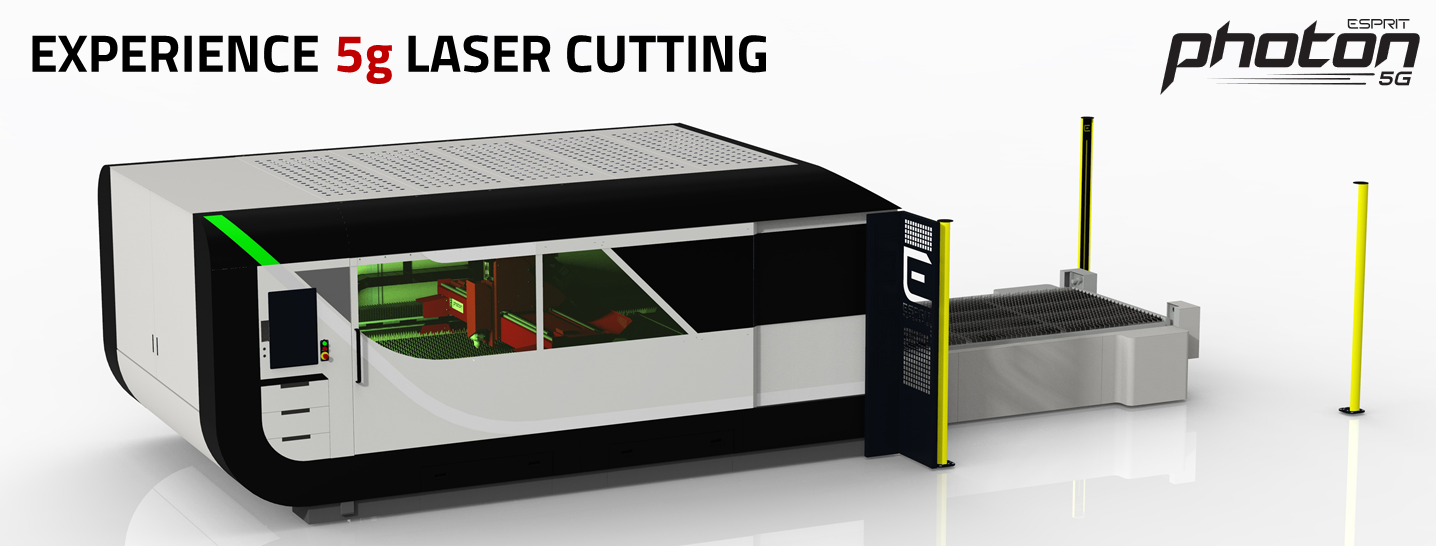

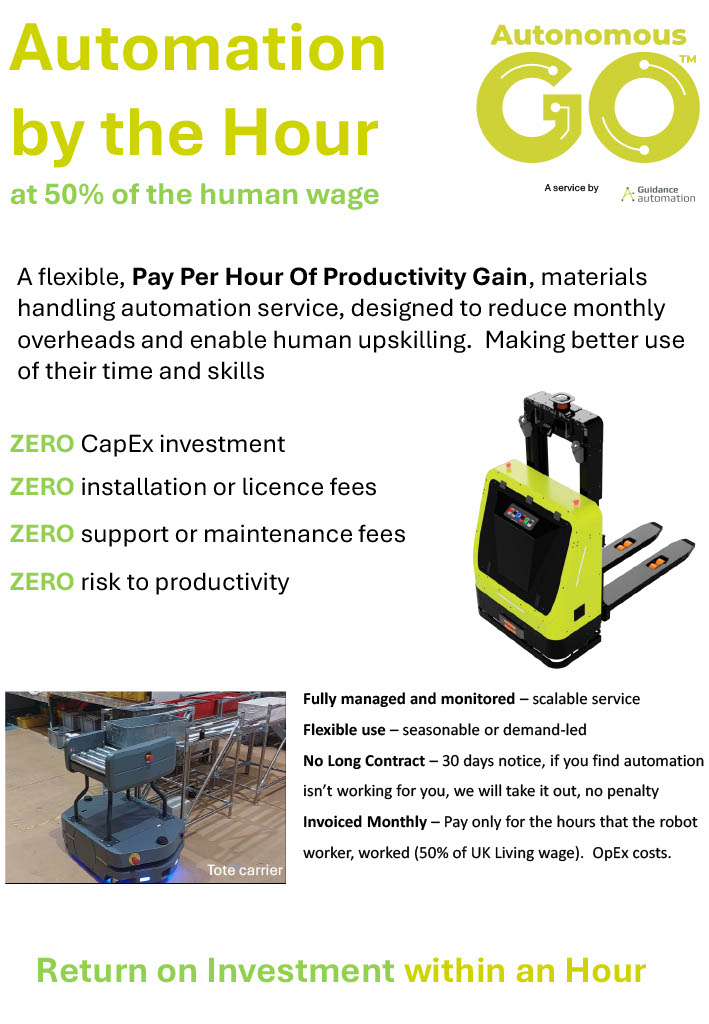

Photon 5G

For businesses that need performance and productivity to go hand in hand with operator control, we proudly present our flagship Photon 5G fiber laser cutter.

Thanks to its aerospace-inspired machine design with hybrid gantry, the Esprit Photon is able to reach staggering vector speeds of 325 m/min, making it a champion in productivity.

To tame the extreme 5 g forces that are generated by this powerful machine, the Photon 5G relies on Esprit’s signature precision-welded bed & gantry design. The robustness of this machine is one the first things our customers notice when seeing it live for the first time.

But there is more…

Despite impressing with its technological prowess, the Photon 5G also redefines ease of use. Thanks to revolutionary features such as Esprit’s LiveNest™, LiveControl™, and LiveGuard™ systems, operating this fiber laser cutter is quick and easy to learn in no time.

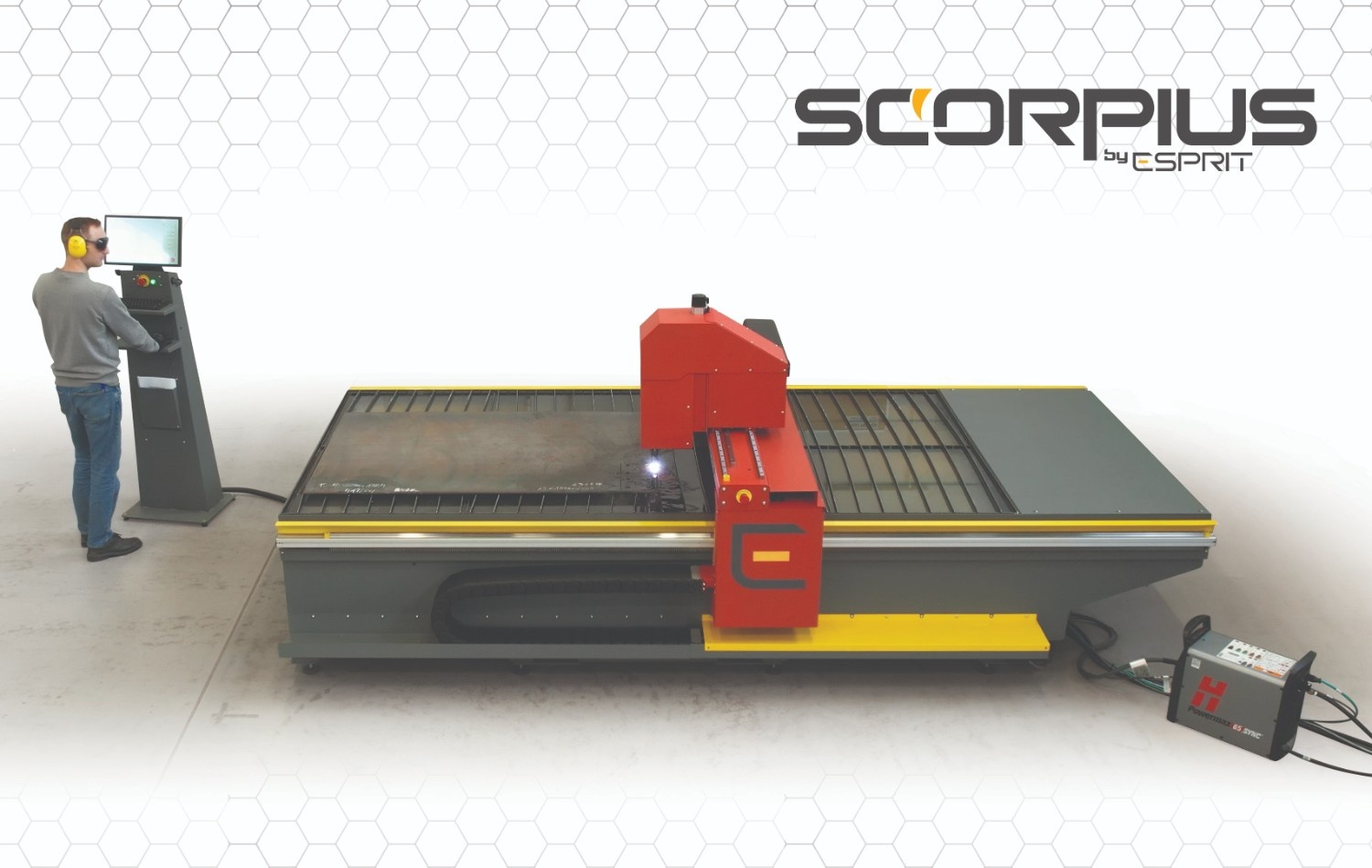

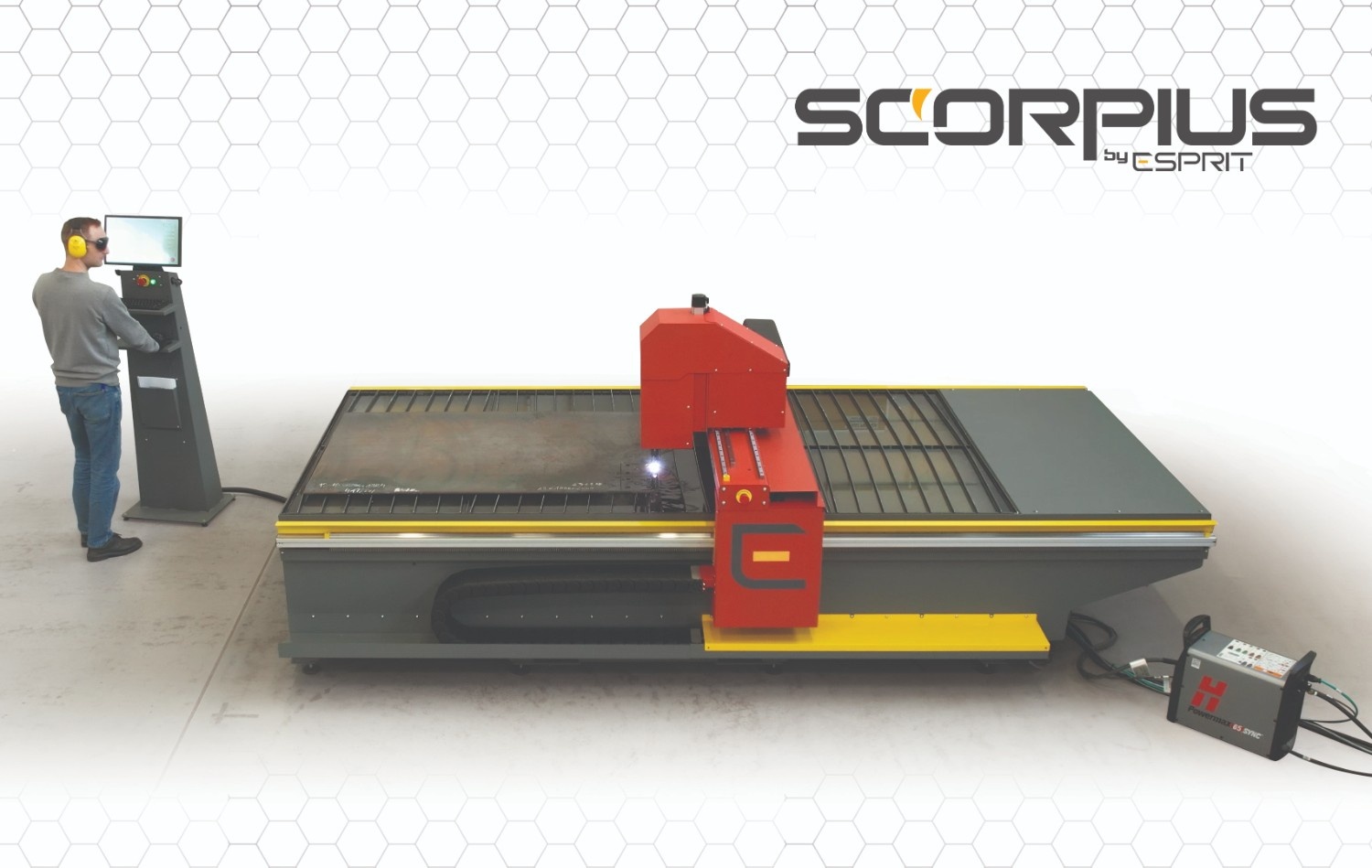

Scorpius

The Scorpius offers reliability and consistent cut quality you’d expect from an industrial plasma machine, but at an affordable price.

Hypertherm’s state-of-the-art EDGE® Connect CNC, dedicated for plasma cutting; syncs perfectly with the Hypertherm Powermax or MAXPRO200 range.

Heavy duty gantry beam and Y-carriage, supported by twin x-axis linear rails provide a robust set-up. Servo motors and planetary gearbox ensure a consistent and repeatable cut throughout the life of the machine.

Thanks to its low investment costs and outstanding performance the Scorpius offers a payback period as low as one year.

The Scorpius is available in 2 versions: the Scorpius X, which features downdraft extraction, and the Scorpius Q, with a water table.

Multibevel

The Esprit plate beveling machine will cut components with a range of bevel details suitable for straight and radius edge weld preps, countersinks, and a range of other component specifications.

The Multibevel has an Esprit-engineered precision bevel head and fully integrated True Bevel technology from Hypertherm for quicker set-up and more accurate bevel cutting.

The Multibevel is a heavy-duty CNC machine tool optimised for plasma bevel cutting applications and integrates with Hypertherm XPR300 or XPR460 plasma cutting systems.

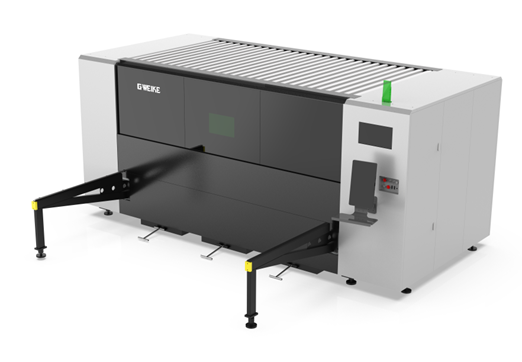

Photon Lite

Take control of your production with a British-built, high-quality and ultra-compact fibre laser machine. Fully supported by our network of UK and Irish service engineers.

With the Photon LITE you can manage all your cutting requirements at a price a growing company can afford.

Produce laser-cut parts on demand, whenever you need them with our easy-to-use CNC.

The Photon LITE is manufactured entirely in the UK with premium European components from Bosch, Precitec and Wittenstein. Choose from either IPG or Raycus CE laser sources to suit your specific requirements.

Fully CE-certified for laser, mechanical and electrical safety. Backed by Esprit engineers and spare parts held in stock in our Nottingham facility.

Photon Lite

Take control of your production with a British-built, high-quality and ultra-compact fibre laser machine. Fully supported by our network of UK and Irish service engineers.

With the Photon LITE you can manage all your cutting requirements at a price a growing company can afford.

Produce laser-cut parts on demand, whenever you need them with our easy-to-use CNC.

The Photon LITE is manufactured entirely in the UK with premium European components from Bosch, Precitec and Wittenstein. Choose from either IPG or Raycus CE laser sources to suit your specific requirements.

Fully CE-certified for laser, mechanical and electrical safety. Backed by Esprit engineers and spare parts held in stock in our Nottingham facility.

Photon 5G

Experience 5 g laser cutting with Esprit’s Photon 5G fiber laser cutting machine. Thanks to its aerospace-inspired machine design, the Esprit Photon 5G can reach staggering vector speeds of 325 m/min, making it a champion in productivity.

Scorpius

The Scorpius offers reliability and consistent cut quality you’d expect from an industrial plasma machine, but at an affordable price.

Multibevel

Our heavy-duty CNC Plasma cutting machine optimised for plasma bevel cutting applications and cutting angled edges.

Multibevel

Our heavy-duty CNC Plasma cutting machine optimised for plasma bevel cutting applications and cutting angled edges.

Download

Photon 5G

Experience 5 g laser cutting with Esprit’s Photon 5G fiber laser cutting machine. Thanks to its aerospace-inspired machine design, the Esprit Photon 5G can reach staggering vector speeds of 325 m/min, making it a champion in productivity.

Download

Photon Lite

Our entry-level laser cutting machine. Experience compact laser cutting with Esprit’s Photon Lite fibre laser machine. With its space-saving design and high-quality European components, the Photon LITE delivers reliable precision cutting for a wide range of materials at an attractive price point

Download

Scorpius

The Scorpius is our entry level plasma machine. It offers reliability and consistent cut quality you’d expect from an industrial plasma machine, but at an affordable price.

DownloadEUROPA TOOL COMPANY LIMITED

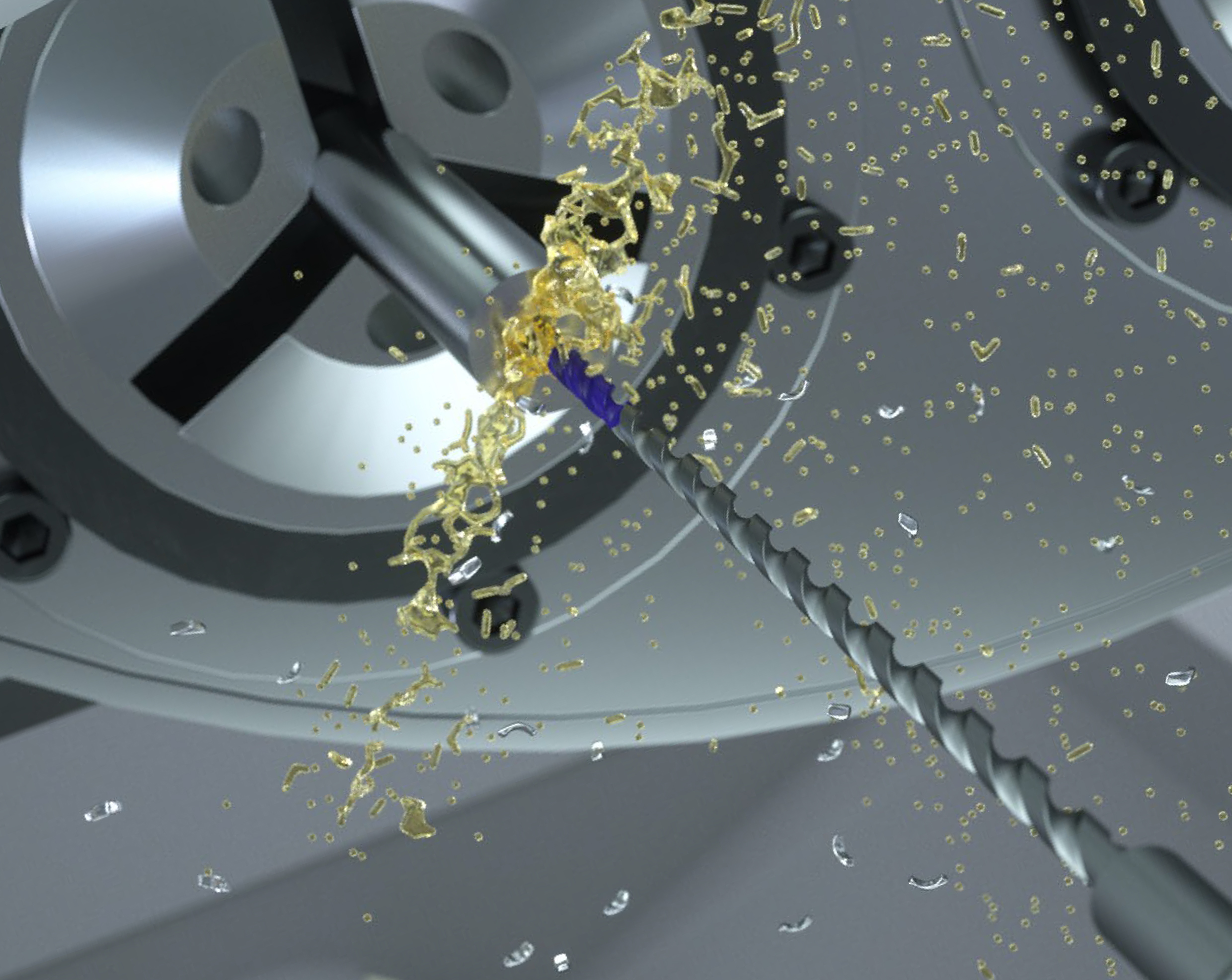

Stand: 6-180

EUROPA TOOL COMPANY LIMITED

Description

Europa Tool Co is a wholly owned subsidiary of the largest global round shank cutting tool manufacturing group, and a market leading supplier of solid carbide tooling in all market sectors such as Aerospace, Automotive, Energy, Medical and many others.

Categories

Address

Unit 2 Kingfisher CourtHemdale Business Park

Nuneaton

Warwickshire

CV11 6GY GB

Website

No products provided.

No videos provided.

No brochures provided.

EUROPEAN SPRINGS AND PRESSINGS LIMITED

Stand: 6-491

EUROPEAN SPRINGS AND PRESSINGS LIMITED

Description

We are leading experts in the field of spring manufacturing and high speed press technology and our products are used in major industrial environments all over the world. We have the latest technology and qualified toolmakers to design and produce the very best bespoke stampings, springs and wire forms.

Categories

Address

Chaffinch Business ParkCroydon Road

Beckenham

BR3 4DW GB

No products provided.

No videos provided.

Welcome to Code A Weld

Operating throughout the UK and further afield, with regional offices in Bristol, London,

Manchester and Aberdeen, Code A Weld's professional services have supported its national and

international customers for over 40 years.

Our core focus is providing RTPO (Recognised Third Party Organisation) Weld Inspection,

Certification and Reporting services. This is supported by and operated alongside fully independent

dedicated services that provide non-destructive and destructive mechanical testing services.

EWM HIGHTEC WELDING UK LIMITED

Stand: 19-619

EWM HIGHTEC WELDING UK LIMITED

Description

EWM Hightec Welding UK Ltd, a subsidiary of EWM GmbH, at the forefront of technology and manufacture of the highest quality arc welding machines and process solutions for manual, mechanised and automated applications.

Our Morpeth based welding specialists provide sales, service & training on all aspects of welding equipment, consumables, PPE and associated equipment and after sales support.

Categories

Address

Unit 2BCoopies Way

Coopies Lane Industrial Estate

Morpeth

Northumberland

NE61 6JN GB

No products provided.

No videos provided.

No brochures provided.

EXPERT TECHNOLOGIES GROUP LTD

Stand: 18-569

EXPERT TECHNOLOGIES GROUP LTD

Description

Expert Technologies Group

Leading manufacturer of intelligent technology solutions

Specialist in delivering World Class industrial automation systems, from special purpose machinery to complete production lines. Any sector, any time.

Ansomat, with over 30 years of experience, stands as a leader in providing operator guidance solutions.

Categories

No categories provided.

Address

Technology Centre30 Sayer Drive Lyons Park

Coventry

Tyne and Wear

CV5 9PF GB

Operator Guidance Technology That Gets It Right – Every Time

Ansomat Operator Guidance turns manual shop floor processes into clear, step-by-step digital instructions that operators can follow with confidence. No guesswork. No tribal knowledge. Just consistent execution, shift after shift.

Designed for real manufacturing environments, the solution guides operators through every task using digital work instructions, projects guidance directly into the work area through augmented reality, and monitors each action with integrated smart tools, vision systems and RTLS, ensuring every step is completed correctly, every time.

Why it works on the shop floor

Reduce human error

Visual, context-aware instructions ensure operators always know what to do next, and what not to do.

Standardize best practices

Capture expert knowledge once and deploy it everywhere, across lines, plants, and shifts.

Shorten training time

New operators get productive faster with intuitive, guided workflows instead of binders and shadowing.

Improve quality and traceability

Mandatory confirmations, data capture, and process checks ensure every step is completed correctly and logged

Built for Operators. Trusted by Engineers.

Configurable workflows without programming knowledge

Seamless integration with existing machines and systems

Scales from a single station to enterprise-wide deployment

The Result

Fewer mistakes. Faster ramp-up. Higher throughput.

A practical way to semi-automate manual processes giving operators the tools they need to be successful.

Ansomat Operator Guidance makes operational excellence repeatable, not dependent on who’s on shift.

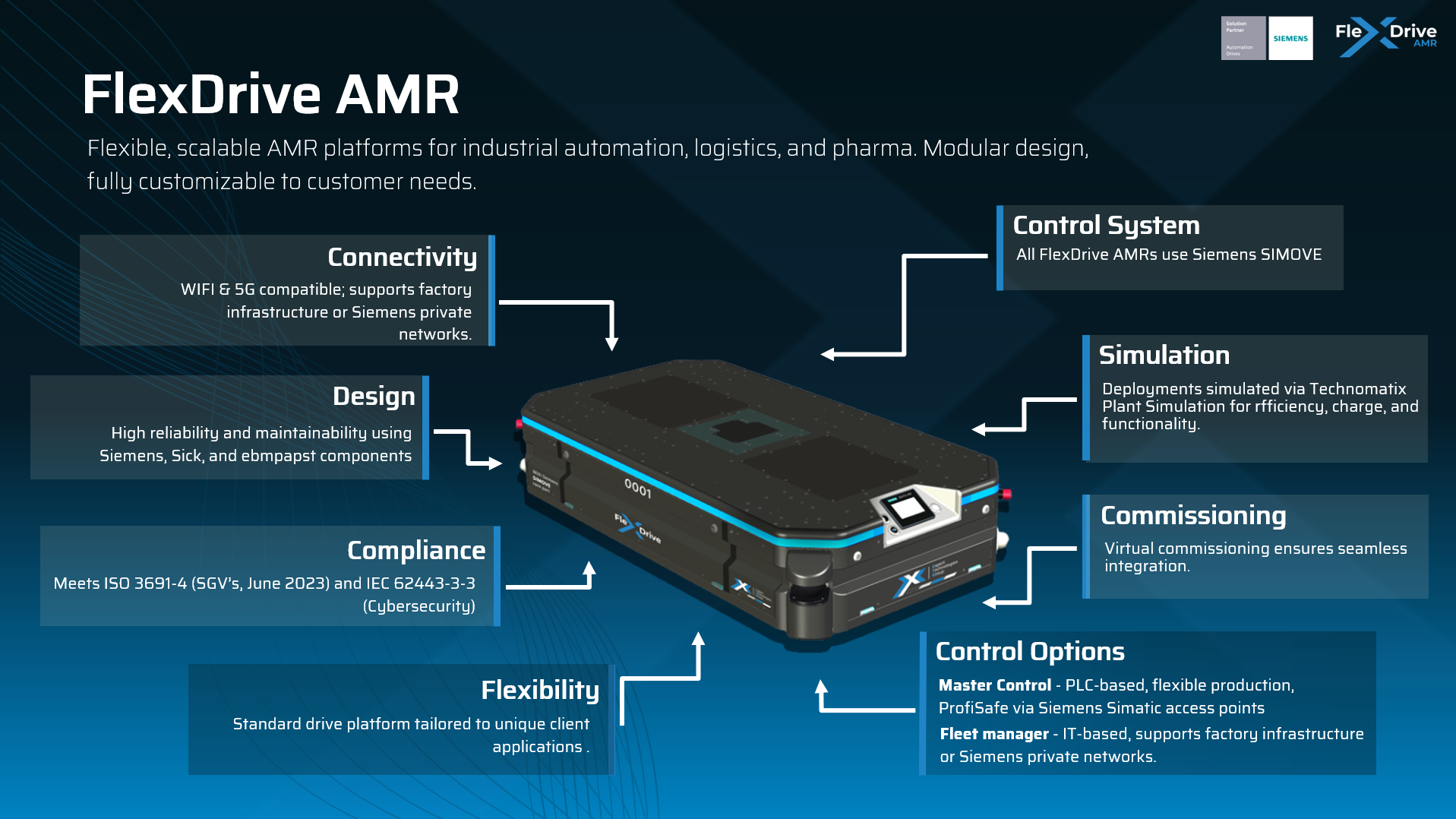

FlexDrive – First UK Designed and Manufactured AMR

All FlexDrive AMRs use Siemens SIMOVE as their core control system. We simulate all AMR deployments through Technomatix Plant Simulation ensuring that the correct number of vehicles, cycle time, state of charge & functionality is achieved, we commission our systems virtually to ensure smooth and seamless integration.

We can control the AMR fleets in two ways :

Master Control – PLC based master control allows for flexible production environments as well as wireless safety via ProfiSafe when using Siemens Simatic access points.

Fleet Manager – IT based fleet manager allows for larger AMR deployments of 100+ vehicles and uses VDA5050 communication

All FlexDrive AMRs are WIFI & 5G compatible and can utilise existing factory infrastructure, as well as separate Siemens private WIFI & 5G networks.

Our vehicles are designed with maximum reliability and maintainability. We utilise proven industrial technology components in their respectable fields (Siemens, Sick & ebmpapst).

All our vehicles have full conformity with the latest standards e.g. ISO 3691-4: (June 2023) for AGVs and IEC 62443-3-3 for Cybersecurity.

At Expert Technologies Group we understand that your AMR application is always unique to you, that’s why our vehicles have been designed not just for one specific function, but as a standard drive platform that can be tailored to meet your specific needs and requirements.

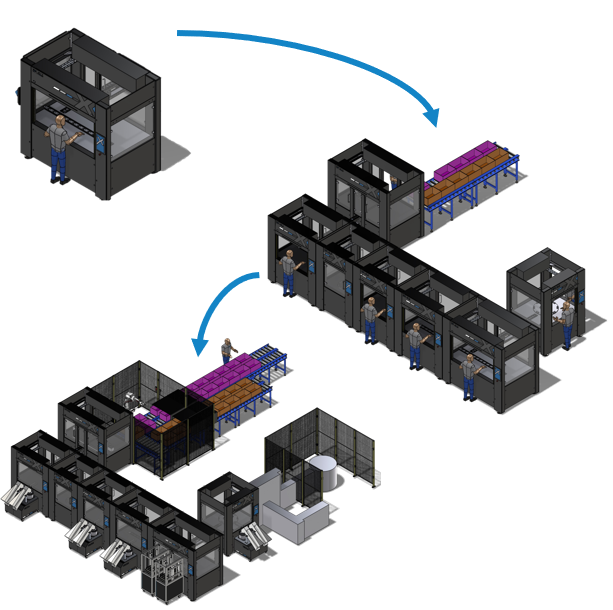

fleXcell – Modular Automation Platform

The fleXcell manufacturing philosophy embraces a future of dynamic change, driven by technological advancement, client need and environmental imperatives.

It provides end-users with an opportunity to develop validated, automated processes early in the product lifecycle.

The modular design means the system can be converted from semi-automated manual ‘islands’ to a fully automated production line for true flexibility.

No videos provided.

No brochures provided.

FABERTEC GROUP UK LTD

Stand: 17-110

FABERTEC GROUP UK LTD

Description

Fabertec Group UK was created to bridge machine manufacturer with fabricator and joiner. By understanding our Client needs, what they going through on daily basis and how quickly they operate we apply an affordable solutions, intuitive software to cut on machines in 2h training and simple design to allow for no hassle maintenance and repairs which does not cost fortune.

Categories

Address

UNIT 2-5 MONSAL PARKATHERTON WAY

BRIGG

DN20 8FW GB

FABERTEC M2 1325 CNC ROUTER – £24,500+VAT – PRESENT ON EXHIBITION

For the most demanding professionals where 10-12 hours shifts may be a everyday norm the FABERTEC M2 CNC CENTRE is a perfect solution. Designed to withstand the challenging tasks, different materials, solid timber, composite panels and any other timber and plastic based products. Fitted as standard with HQD 9kW (12hp) air cooled spindle together with heavy 8-10mm steel structure fully welded, stress relieved and all surfaces for runners/linear bearings cnc milled to keep all axis perfect. It can cut through thick boards in one pass like a butter.

All M2 cnc machines are fitted with Automatic Tool Changer ATC with 12 tools at disposal in the carousel type storage. Located close to spindle is the quickest position for cnc to change tools. Of course all tool holders, starting bits and collets are included in the package so you can start your projects from day one. Vacuum table with T slot clamps with air cooled 7.5kW vacuum pump installed as standard. For more demanding cuts with smaller elements or if you will choose bigger table we strongly recommend to upgrade to 11kW KVE360 vacuum pump which will be much more efficient.

By standard all of our M1 and M2 CNC ROUTER models are equipped with coolant mist to allow you to cut and engrave large format aluminium sheets. It may be large pivot entrance aluminium doors or hinge on the alu frame or even recess in larger alu block which will not fit to typical milling cnc. The M2 is there to help you with your aluminium processing where other machines cannot.

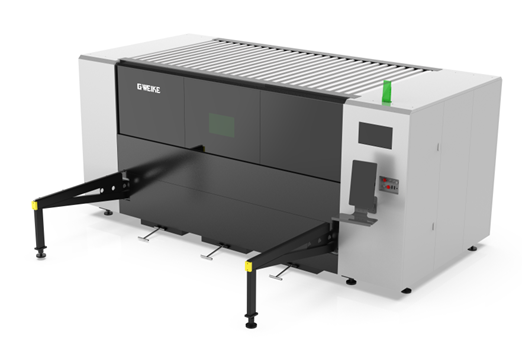

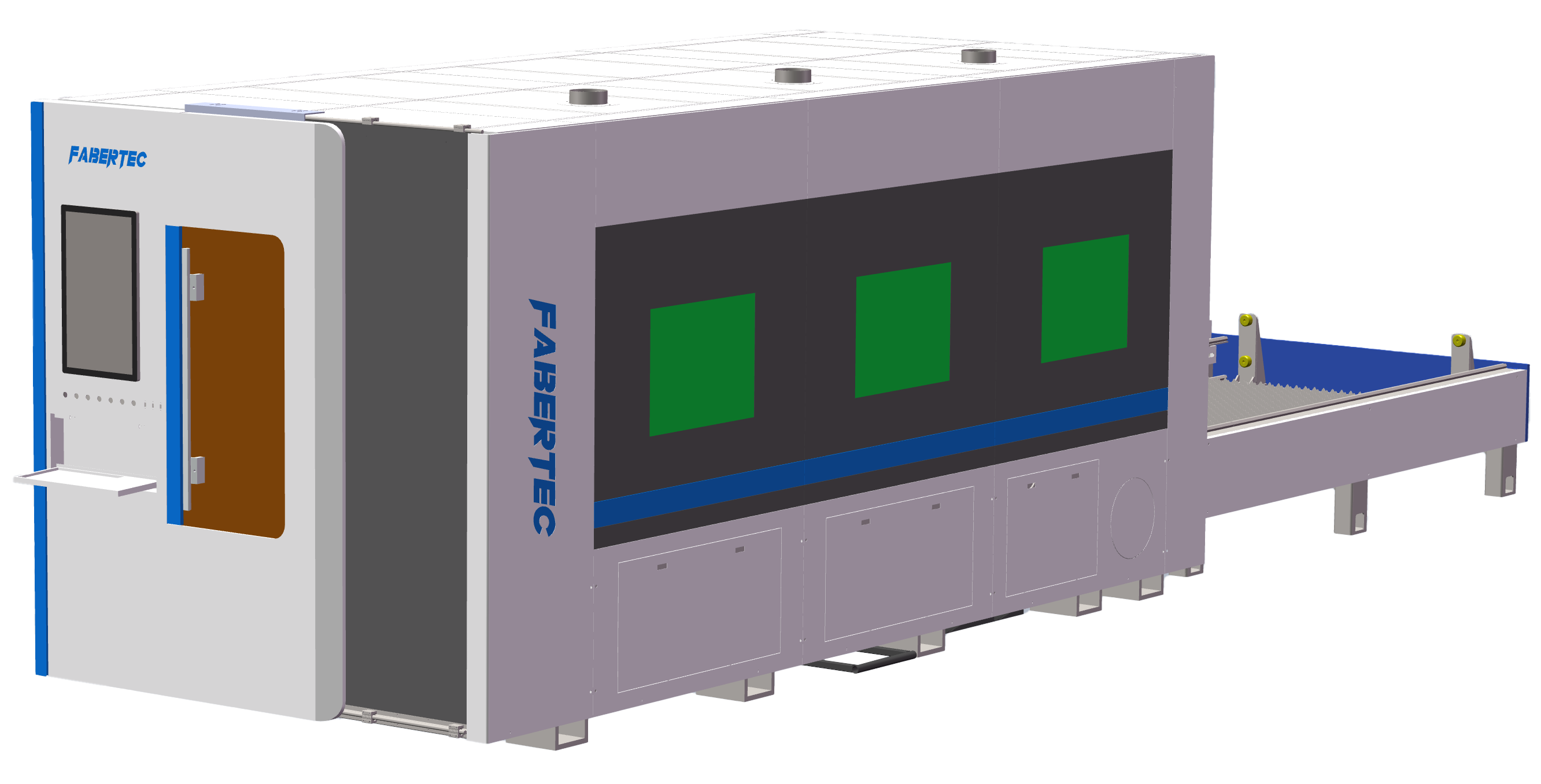

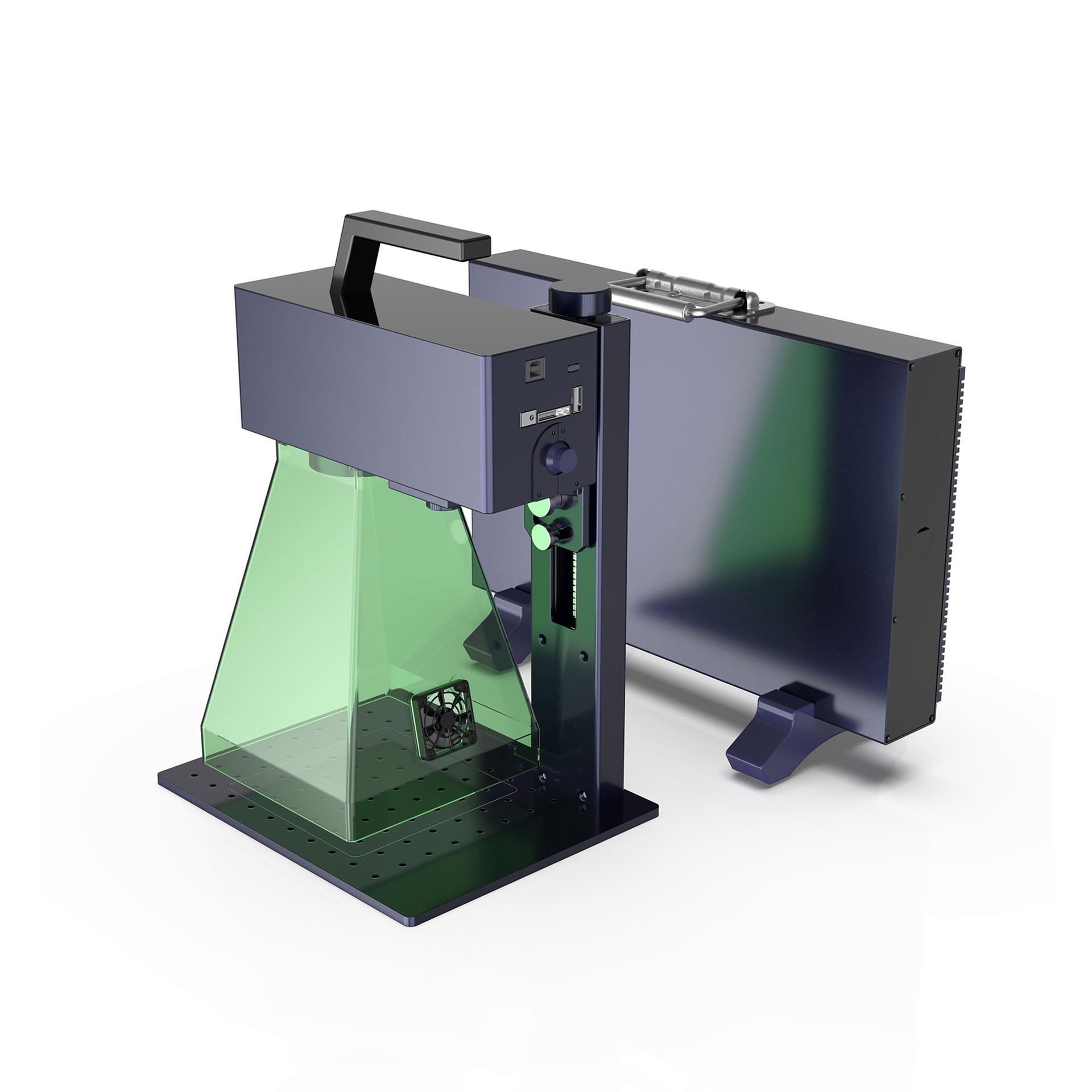

FABERTEC FL4 FIBER LASER CUTTER – STARTS FROM £59k+VAT FOR 2kW 1530 – PRESENT ON EXHIBITION

Are you a laser cutting subcontractor? Do you process laser cutted parts 24 hours a day, 7 days a week? If your answer is yes, then the FABERTEC FL4 is for you.

FL4 model is the closest to what you see from well-known brands for £300k-800k, but of course, our prices start from £59k +vat for 2kW laser source. Designed to operate as economically as possible, FL4 is a robust machine able to handle a range of applications to maximize the value of your investment.

FL4 maximises uptime with an integrated shuttle table system, which allows one table to be loaded/unloaded while cutting on the other table. Table changeover is completed in just 45 seconds. Sheet edge recognition will adjust all your vectors to unaligned metal sheet on slats. Automatic height adjustment, laser head collision prevention and frog leap, will keep you cutting all day long without any stopovers.

Micro Joint will allow you to cut tiny pieces, leaving a tab between elements to remove larger sections, instead of fishing out for small parts in floor drawer. Fly cutting, circle centering, frame border and other are adding to efficiency in your operations.

With the strong focus on safety FL4 is fully enclosed with CCTV camera's inside and outside showing you 1st and 2nd pallet table. The rear open table is surrounded by light barriers, to prevent any damage to operator or loader when tables are exchanging. To improve cutting efficiency barriers only work during table movement, so loader can clean all finished elements and load new sheet, without engaging emergency stop by walking between light barriers.

As a standard, the CAD/CAM software is simple and intuitive. In the past, we had a situation where operator who was previously cutting on Amada or Trumpf machines or even plasma cutters was able to efficiently operate Fabertec machines after literally 15 minutes of training.

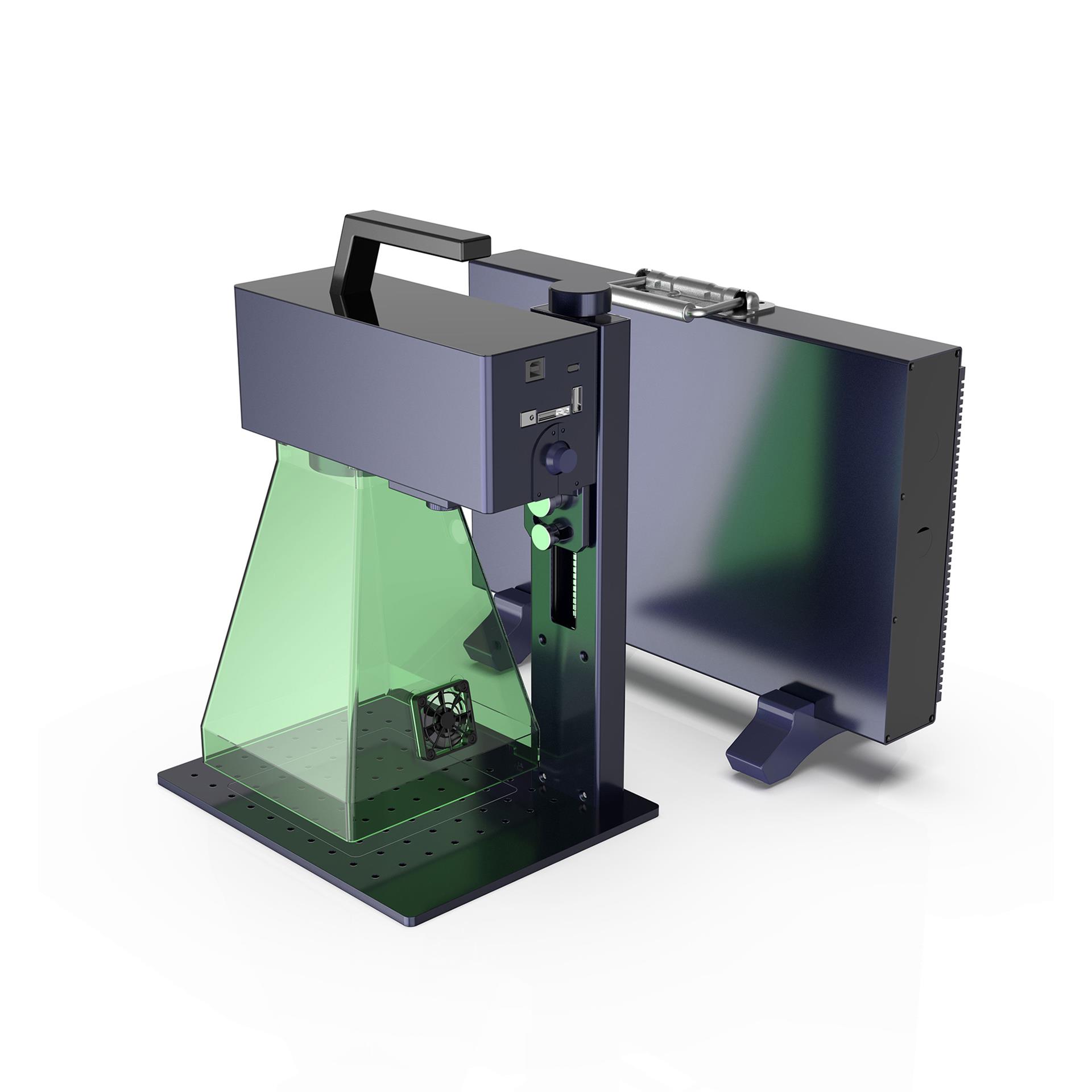

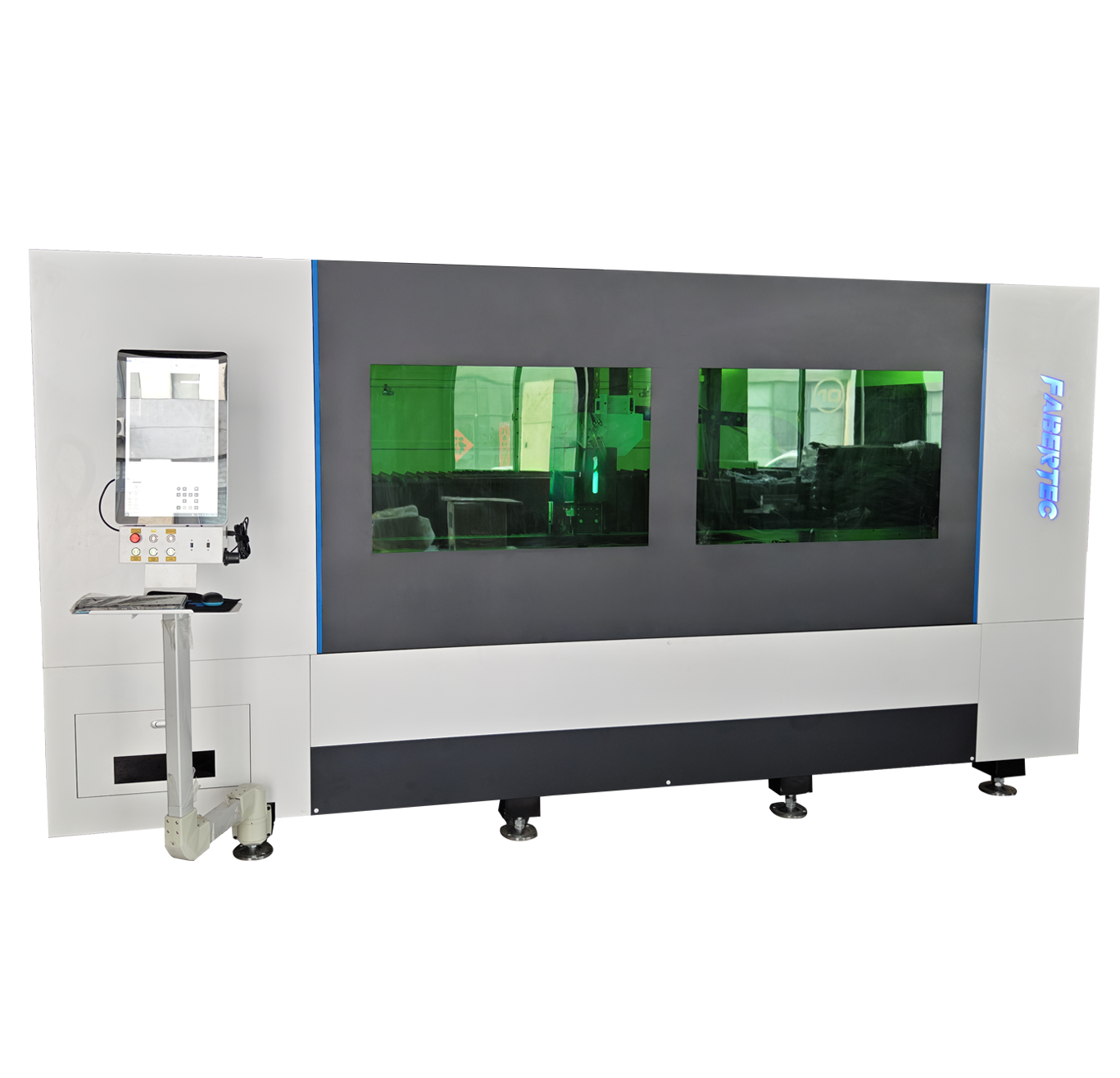

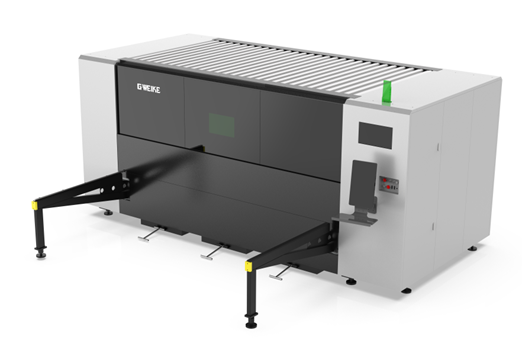

FABERTEC FL3 FIBER LASER CUTTER – STARTS FROM £42k+VAT FOR 1kW 1325 – PRESENT ON EXHIBITION

This powerful machine is equipped with a single table with full enclosure designed to provide unmatched precision. Included as a standard, fully retractable table will allow you to clear all parts quickly and load new sheet without straining your back. Also, as FL3 it is fully enclosed with optional metal dust extraction system will keep your workshop dust free and operators in particles-free environment.

All the machines’ parts and electronics are integrated in the body. Only chiller and larger kW laser sources are placed on the side or back of machine. This solution helps with limited workshop spaces, which most of us has to deal with.

As a standard, in every FL3, there are 3 separate gas inlets, controlled by electric valves from the software level. Compressed Air, Oxygen and Nitrogen can be changed in a second. We are fabricators – we understand you don’t have time to run around the machine and change hoses every 2 hours.

As with other models, we always design our fiber lasers with upgradeability in mind. Laser head, controller, software and structure of the machine is prepared for up to 6kW laser source power. To upgrade your cutting capability, you just need to replace laser source and chiller from 2kW to 6kW for example. From 6kW to 15kW we have to even further upgrade components of the FL3 to cope with higher speeds and thicker metal sheets.

No brochures provided.

FABSTATION

Stand: 17-159

FABSTATION

Description

Our state-of-the-art technology blends the tangible world with virtual augmentations, facilitating precise measurements and seamless 3D model visualizations of complex steel and metal assembly structures.

Embrace the power of augmented reality and unlock limitless possibilities within metal and steel fabrication and QC. FabStation integrates smoothly with popular design and detailing software.

Categories

Address

Eterio Realities328 Wale Rd #132

Victoria

British Columbia

V9B0J8 CA

FabStation

FabStation – User Journey

Watch John's as he learns the benefits of FabStation and how you can teach an old dog new tricks!

FabStation – Instant ROI!

Learn how FabStation can dramatically improve the quality of your product using our revolutionary new augmented reality-based QC system for inspection.

No brochures provided.

5S SUPERSTORE & GO INDUSTRO

Stand: 18-739

5S SUPERSTORE & GO INDUSTRO

Description

GoIndustro and 5S Superstore partner to deliver robust 5S, lean, and visual management tools. Combining durable UK-made products with specialist 5S solutions, they simplify workplace organisation, boost safety, cut waste, and help teams build and sustain efficient, high-performing work environments.

Categories

Address

7 Victoria RoadTamworth

Staffordshire

B79 7HS GB

ITAR and Aerospace Signage

Our ITAR and aerospace signage delivers clear, compliant communication for highly regulated environments. Designed for maximum visibility and built from durable, aerospace-grade materials, these signs help teams identify controlled areas, protect sensitive data, and maintain strict regulatory standards. With crisp graphics and unmistakable messaging, they strengthen security, reduce compliance risks, and support a culture of precision and accountability.

CNC Storage

Our CNC storage systems are designed to protect, organise, and streamline access to valuable CNC tooling. With durable, precision-engineered holders, drawers, and racks, they keep tools secure, clearly arranged, and ready for immediate use. By reducing search time, preventing damage, and supporting efficient setups, our CNC storage solutions help machinists work faster, safer, and with consistent accuracy—maximising productivity on every shift.

5S Red Tags

Our 5S Red Tags and Tag Stations make sorting fast, clear, and consistent across any workspace. Bold, easy-to-use red tags help teams quickly identify items for review, relocation, or removal, driving immediate 5S improvements. Paired with organised tag stations and complete tag kits, you get everything needed to launch or sustain an effective red-tagging process. Durable, simple, and highly visible, they streamline decision-making and keep workplaces clutter-free and continuously improving.

Forklift Attachments

Our forklift attachments expand the capability of your fleet, turning every forklift into a versatile, multi-purpose workhorse. Engineered for strength, safety, and reliability, each attachment enhances handling, lifting, and material movement while reducing manual effort and downtime. From specialised lifts to custom solutions, they boost productivity, improve workplace safety, and help teams move more—faster, smarter, and with total confidence.

Lock Out Tag Stations

Our Lockout Tagout Stations provide a central, highly visible hub for all essential LOTO devices, ensuring maintenance and repair tasks are carried out safely and compliantly. Built for industrial durability, each station keeps padlocks, tags, and hasps organised and ready to use, reducing delays and preventing accidental energisation. Clear, structured, and easy to deploy, they strengthen safety culture and help teams maintain full control over hazardous energy procedures.

5S Implementation Kits

Our 5S Implementation Kits provide everything you need to launch or refresh a successful 5S programme—all in one complete package. Packed with essential tools like floor markers, red tags, cleaning supplies, signage, and visual controls, each kit accelerates organisation, boosts safety, and builds sustainable workplace discipline. Designed for quick rollout and long-term impact, they make adopting 5S easier, faster, and more effective for any team.

Tool Board Shadow Vinyl

Our tool board shadow vinyl makes organisation effortless by giving every tool a clear, permanent home. With high-contrast, precision-cut silhouettes, it delivers instant visual control—so missing tools stand out and search time disappears. Durable, easy to apply, and fully customisable, it’s the ideal way to strengthen 5S, reduce downtime, and keep workspaces running at peak efficiency

Unique Safety Signage

Our life-sized PPE signs provide powerful, real-scale visual cues that workers can’t miss. By displaying protective equipment at true-to-life size, they create instant recognition, strengthen safety awareness, and boost compliance. Made from durable, industrial-grade materials, these signs deliver clear, high-impact guidance that helps keep every workplace safer and more alert.

5S Cleaning Stations

Our 5S Cleaning Stations make workplace housekeeping simple, visible, and consistent. Designed for durability and daily use, each station organises essential cleaning tools in one clearly marked location, reducing downtime and promoting ownership. They support 5S, improve safety, and help teams maintain a clean, compliant, and high-performing workspace with ease.

Workplace Organisation

Our workplace tool storage solutions are engineered to keep every tool organised, visible, and ready for use. From shadow boards to custom storage systems, each product supports 5S and lean principles by reducing search time, eliminating clutter, and improving workflow. Built for tough industrial environments, they help teams stay efficient, consistent, and in full control of their workspace.

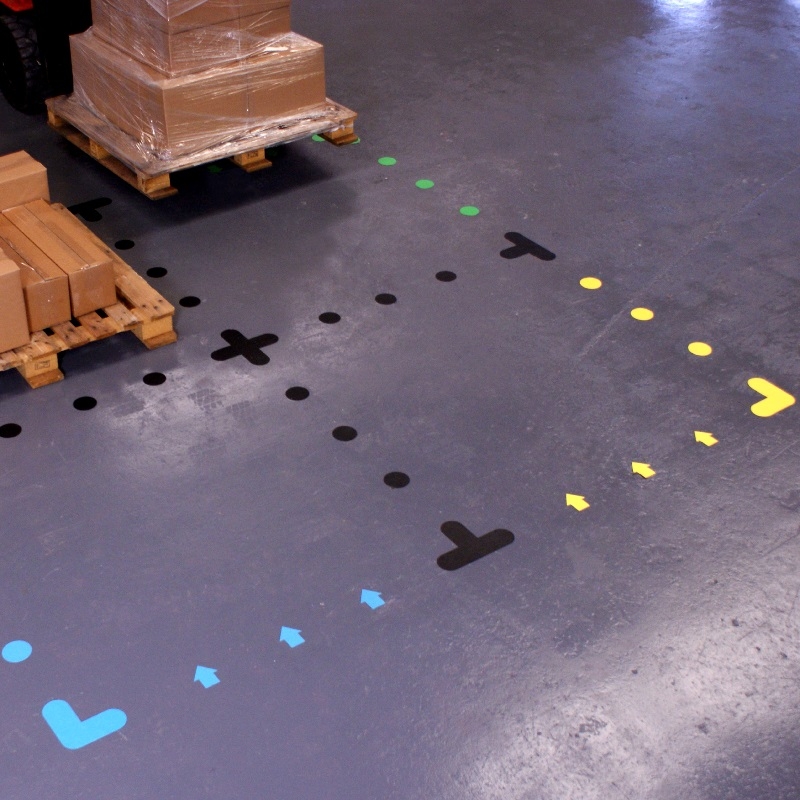

Floor Marking

Our floor marking products are designed to transform busy workplaces into safer, more efficient, and visually organised environments. Built for industrial durability, they provide clear guidance for walkways, hazards, storage zones, and workflow areas. Easy to apply, highly visible, and long-lasting, our markings help teams work smarter, reduce accidents, and maintain consistent 5S and lean standards across the facility.

Zone Guard – Visual Control Made Simple

ZONE GUARD is a quick-install, high-impact solution for organising and protecting your workspace. Available in a variety of shapes, sizes, and colours, it allows you to clearly define zones such as walkways, first aid points, spill kit areas, team spaces, staging areas, and more.

Not limited to floors, ZONE GUARD also adheres to walls, doorways, and most surfaces—giving you full control to manage and optimise your facility.

5S Superstore – Smarter Spaces, Leaner Places

The 5S Superstore exists to help companies resolve their most frustrating day to day operational challenges and support their long-term company strategies. We continue to strive in being the world leader in creative solutions for the workplace. Our products have already helped thousands of businesses from sectors such as aerospace manufacturing, automotive assembly, warehousing and many other sectors of industry.

GoIndustro – Keeping the Cogs of Industry Turning

Go Industro exists to help companies resolve their most frustrating day to day operational challenges and support their long-term company strategies. We continue to strive in being the world leader in creative solutions for the workplace. Our products have already helped thousands of businesses from sectors such as aerospace manufacturing, automotive assembly, warehousing and many other sectors of industry.

No brochures provided.

FACCIN GROUP - QUALIMACH LIMITED

Stand: 6-590

FACCIN GROUP - QUALIMACH LIMITED

Description

From the 1960s, Faccin Group has been one of the foremost companies in the world in metal forming machines.

It offers a comprehensive range of plate rolls, angle rolls, dished head lines, and special solutions thanks to its three brands - FACCIN, BOLDRINI, and ROUNDO.

Visit Faccin Group at stand 6-590, along with our trusted partner Qualimach Ltd.

Categories

Address

Old Town Hall2a High Street

Sheffield

S1 2DE GB

4HEP-MPE 4-roll Direct Electric-Drive Plate Roll

The 4HEP-MPE is an hybrid model (electric-hydraulic) that can lead to remarkable cost savings, as energy consumption costs can be reduced by up to 35% reduction in operating costs, making it a highly lucrative investment with a great return on ROI. The Faccin hybrid design allows to reach extraordinary rolling speeds compared to other exhisting machines, resulting in an impressive surge in productivity.

In addition, the 4HEP-MPE ensures a noise-free experience, with a remarkable reduction of approximately 15 decibels, and boasts many ergonomic advantages for machine operators.

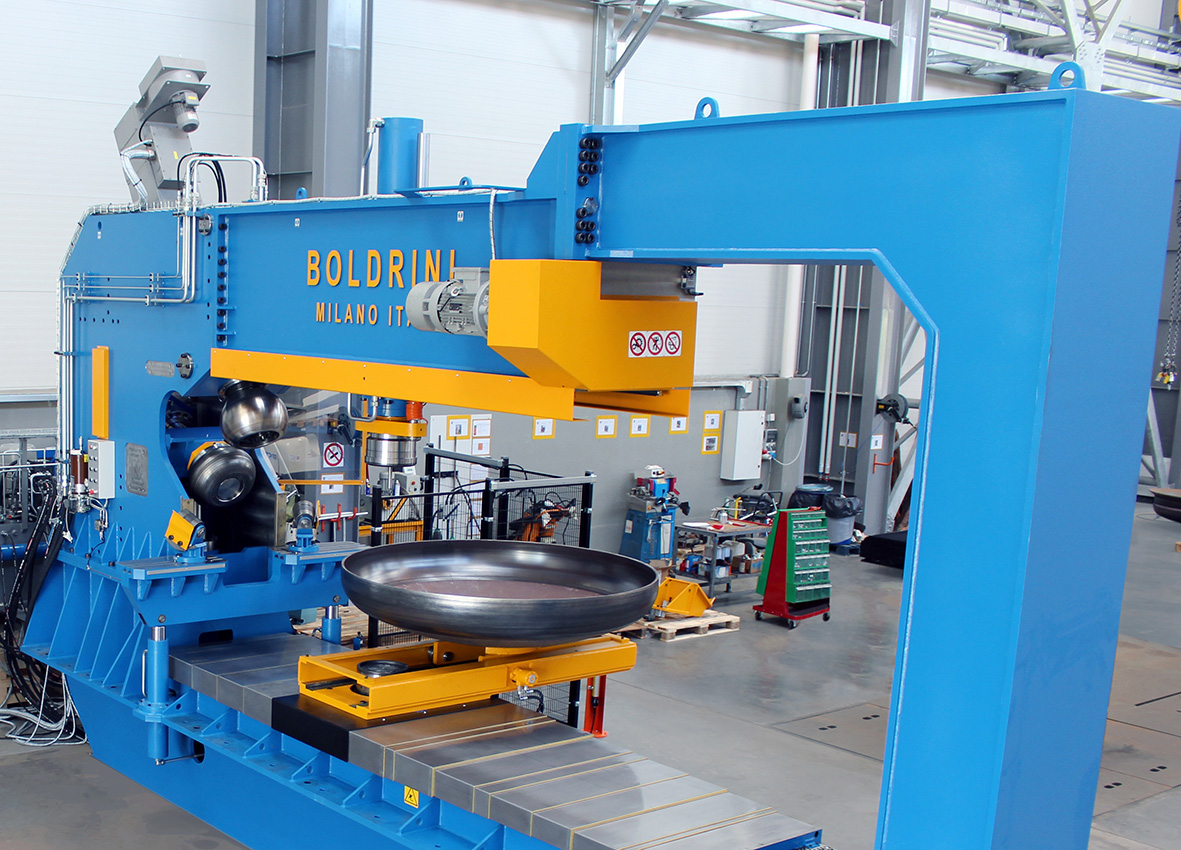

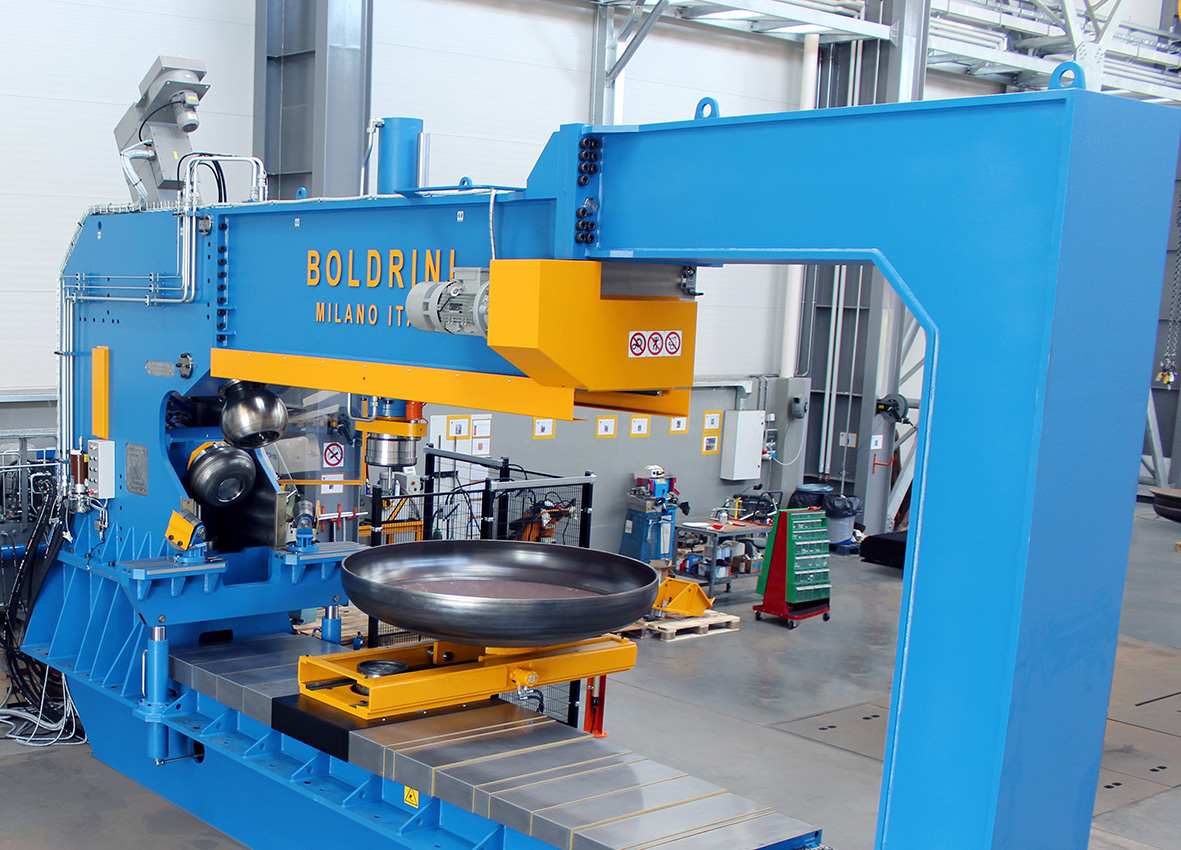

BOLDRINI Dished End Presses and Flanging Machines – Excellence as Standard

BOLDRINI is part of Faccin Group and it is globally recognized as a leader in the production of hydraulic dished end presses and flanging machines since 1905. BOLDRINI provides solutions renowned for their ecellence, reliability and durability, with more than 10,000 machines intalled worldwide.

The top-category machines are the PAO Portal Frame Press, available in a range from 150 to 5000 Ton, and the RIBO Flanging Machine, available with capacities in cold forming ranging from 2mm to 80mm, and hot forming up to 200mm.

BOLDRINI - a brand of Faccin Group

ROUNDO Angle Rolls – The One, The Only, THE ORIGINAL

Founded in 1964, ROUNDO is the leading manufacturer of section bending machines, offering the widest selection of angle rolls on the market.

ROUNDO machines are world-renowned for their outstanding performances, extreme reliability, and top-notch quality of their components. Our portfolio includes more than 20 different machine sizes, from the R-3 - the smallest model - to the R-16-S - the biggest one.

Thanks to a high number of sold Roundo machines in the market and our international branches, Faccin Group guarantees immediate assistance and spare parts availability to Roundo customers all over the world.

Angle Rolls are also offered by our brand FACCIN.

ROUNDO - a brand of Faccin Group

FACCIN Plate Bending Machines, Angle Rolls and Dished Head Lines

The brand FACCIN, part fo the Faccin Group, specializes in the design, construction and sale of Plate Bending Machines, Section Bending Machines and Dished End Lines, boasting the largest portfolio of metal forming machines worldwide.

We provide cutting-edge equipment to form sheet metal plates in a wide range of thicknesses, from thin to thick plates, guaranteeing the maximum accuracy in each step, productivity and reliability throughout the years.

FACCIN provides several different models of plate bending machines to satisfy a variety of production needs and applications, such as Automatic Wind Tower Lines, HVAC Lines, Pressure Vessels, Tanks, Shipbuilding and many more.

FACCIN selection of angle rolls are advanced, reliable, and accurate, and can provide superior bending quality along with high productivity. These machines are capable of bending steel, stainless steel, and aluminum profiles and beams of various shapes and sizes.

Finally, FACCIN provides cutting-edge dishing presses for a complete automation of the process. These machines offer maximum reliability and can satisfy the needs of dished heads manufacturers in terms of achieving tolerances and lamination reduction.

The top-products of this category are PPM+MA, BF and PPH models.

All of these machines are also provided by our brands BOLDRINI and ROUNDO.

FACCIN - a brand of Faccin Group

FACCIN: Heavy-Duty Plate Roll for Monopiles & TP | Jackets | Tripods Manufacturing

Powerful 3-roll plate roller with variable geometry, model HAV-4x240, the ideal solution for rolling and calibrating cylindrical and conical shapes used in the construction of offshore wind tower foundations such as monopiles & TP, jackets and tripods. Capable of achieving tight tolerances of roundness and performing the job 24/7.

Maximum plate width: 4200 mm

Maximum rolling thickness: 240 mm

Maximum pre-bending thickness: 200 mm

The machine is easily handled by a SIEMENS CNC with camera system.

Do not hesitate to contact our Wind Towers Division at [email protected]. A team of highly skilled professionals is available to assist you in your next wind project.

FACCIN Wind Energy Product Portfolio

Download

BOLDRINI Product Portfolio

Download

ROUNDO Section Bending Machines – R series

Download

FACCIN Products and Services

FACCIN, now part of the FACCIN Group, engineers, designs, and manufacturers the widest range of energy-efficient metal forming machines in its own production facility.

DownloadFAIRFIELD CONTROL SYSTEMS

Stand: 17-261

FAIRFIELD CONTROL SYSTEMS

Description

No company profile provided.

Categories

Address

Randall Park WayRetford

DN22 7WF GB

Website

No website provided.

No products provided.

No videos provided.

No brochures provided.

FANUC UK LIMITED

Stand: 18-449

FANUC UK LIMITED

Description

The FANUC Corporation is a world leader in factory automation for CNC control systems, robots and production machinery (ROBODRILL, ROBOCUT and ROBOSHOT). With 271 locations supporting 109 countries worldwide and more than 8,200 employees, FANUC offers a dense network in sales, technical support, research & development, logistics & customer service.

Categories

Address

FANUC UK LtdSapphire Way

Ansty Buiness Park

Coventry

Midlands

CV7 9DR GB

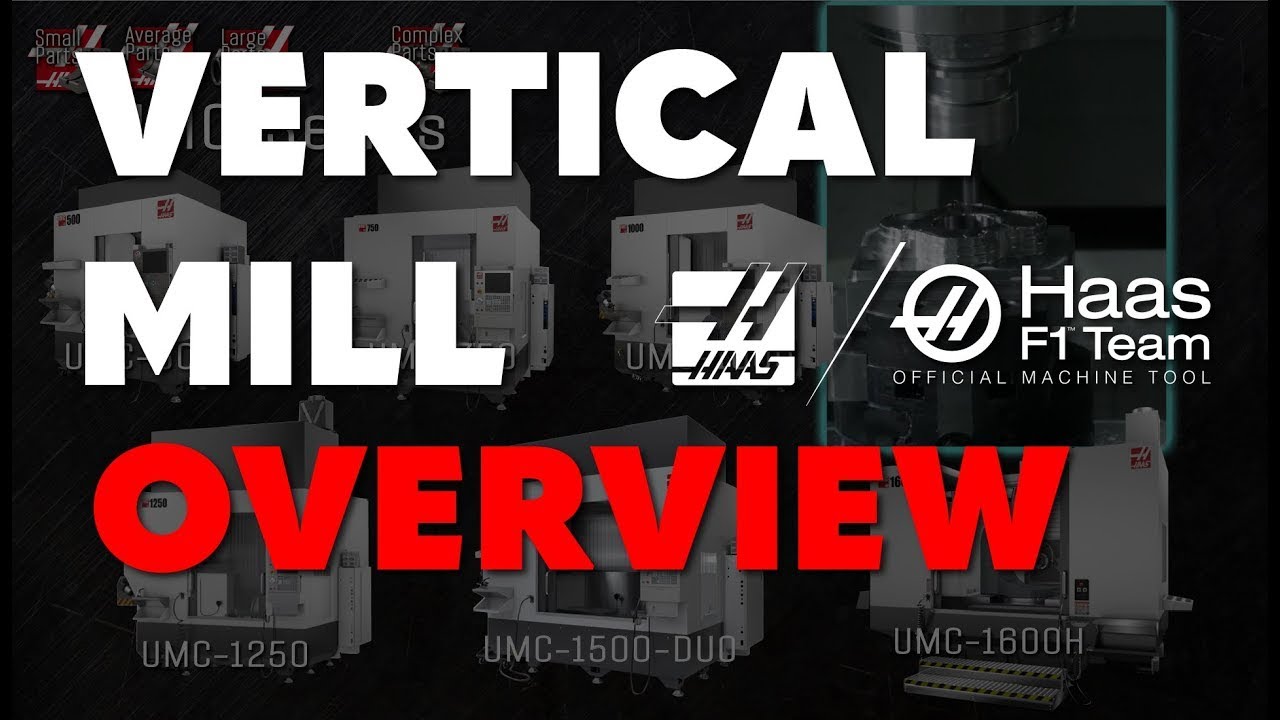

CNC

ROBOSHOT

ROBOT

ROBOCUT

ROBODRILL

No brochures provided.

FARO CREAFORM

Stand: 19-649

FARO CREAFORM

Description

FARO® is a business of AMETEK®, Inc. who enables manufacturers to benefit from contact and non-contact 3D laser scanning measurement solutions.

Categories

Address

1a Great Central WayButlers Leap

.

Rugby

Rugby

CV21 3XH United Kingdom

Gage Max FaroArm®

The most accurate and affordable portable measurement arm.

Performing inspections with traditional hand tools is time-consuming and creates clutter on the shop floor. The Gage Max FaroArm transforms the process, allowing machine shops and small production lines to meet even the most demanding quality specifications with one efficient, sleek, rugged coordinate measuring machine (CMM). The Gage Max FaroArm portable CMM sets up in seconds and delivers precision measurements for quick comparison against nominal CAD data.

FARO® Vantage Laser Trackers

FARO® VantageS6 Max and VantageE6 Max Laser Trackers enable you to build and inspect products by measuring quickly, simply and precisely with exceptional portability. The Vantage Max Laser Trackers offer comprehensive, large-volume 3D measurement up to 80 meters, significantly streamlining your processes and reducing inspection cycle times while ensuring complete confidence in the results.

New to the Vantage Max is more accurate 6 degrees of freedom (6DoF) measurement capabilities via the optional 6Probe, which enables precise measurement of hidden areas and small features. 6DoF probing helps speed up your inspections and reduce the number of device moves, resulting in a productivity improvement of 20% compared to lower accuracy probes.

Quantum Max FaroArm®

Quantum Max FaroArm and ScanArm

Since 1995, FARO® has produced the world’s most trusted portable CMM—the FaroArm®. When it comes to performing accurate 3D measurement and inspection on small to medium sized parts, no tool can match the utility, speed and accuracy of the FARO ScanArm.

Leading aerospace, machining, assembly, and automotive manufacturers rely on this highly versatile precision measurement device to easily capture the data they need on the shop floor, in the field and in any environment including extreme temperatures. And when a part or tool is so difficult to reach that contact probes cannot capture all of its measurements, manufacturers utilize the non-contact functionality of the FARO Quantum ScanArm to do the job. At the heart of the Quantum ScanArm is the Laser Line Probe (LLP), capable of capturing tens of millions of data points with ease.

Now, the tradition continues with the all-new Quantum Max ScanArm and its three hot-swappable LLPs that meet any measurement need. With options to dramatically increase the scanning speed or resolution, the FARO® Quantum Max FaroArm gets the job done as quickly and precisely as possible. With maximum flexibility, extended arm reach and a redesigned end effector with dual kinematic LLP mounts, value and productivity is maximized by over 30%.

The Quantum Max is the fastest, most detailed non-contact measuring machine available on the market today, accelerating project completion time while enhancing overall productivity.

Quantum Max with Multiple Laser Line Probes Solves the One size fits all Challenge

When it comes to performing accurate 3D measurement or inspection on small-to medium-sized parts, no tool can match the utility, speed, and accuracy of an optical portable measurement arm — a ScanArm.

The New Vantage Max Laser Tracker

The FARO Vantage Max is a high-accuracy portable inspection tool that provides you with a 20% productivity improvement, plus increased ease of use and precision. Reduce your time spent on device moves and tooling changes with FARO® VantageS6 Max and VantageE6 Max Laser Trackers.

With improved 6DoF accuracy, the Vantage S6 Max and Vantage E6 Max allow you to reduce inspection time and improve productivity, along with streamlined processes and more precise measurements of hidden areas.

With the higher accuracy of the Vantage Max, users can probe more points beyond the line of sight and without tooling changes.

The FARO Gage FaroArm

As accurate as a fixed CMM, faster than hand tools

Gage Max FaroArm®

The most accurate and affordable portable measurement arm

Performing inspections with traditional hand tools is time-consuming and creates clutter on the shop floor. The Gage Max FaroArm transforms the process, allowing machine shops and small production lines to meet even the most demanding quality specifications with one efficient, sleek, rugged coordinate measuring machine (CMM). The Gage Max FaroArm portable CMM sets up in seconds and delivers precision measurements for quick comparison against nominal CAD data.

Quantum Max FaroArm®

The global standard in contact measurement arm technology

What if you could capture every measurement of a complex part, tool or mold just by touching it? You can — with the Quantum Max FaroArm, the world’s leading portable coordinate measuring machine (CMM). Leaders in aerospace, machining, assembly and the auto industry rely on the FaroArm portable CMM to easily capture precise measurements on the shop floor and in the field, even in extreme temperatures.

FASTEMS

Stand: 18-659

FASTEMS

Description

Fastems supplies intelligent automation and digitalisation solutions for high-mix-low-volume CNC manufacturing. We are an open integrator and a family-owned business with 40 years of automation experience, close to 5000 installations and main markets in Europe, North America and Asia. Our mission is to help metalworking manufacturers improve their productivity and profitability.

Categories

Address

One Bartholomew CloseLondon

London

City of London

EC1A 7BL GB

Manufacturing Management Software (MMS)

MMS is the production control software of all Fastems automation solutions, as well as a stand-alone software to help planning and organizing non-automated production cells. MMS plans, runs and monitors high-mix production – all in one.

The basic idea is to integrate production planning, production resources and machinery into a single software that operates your high-mix-low-volume CNC production in timely and economical manner. From a single machine tool to tens of them, MMS already is the choice of thousands of CNC manufacturers

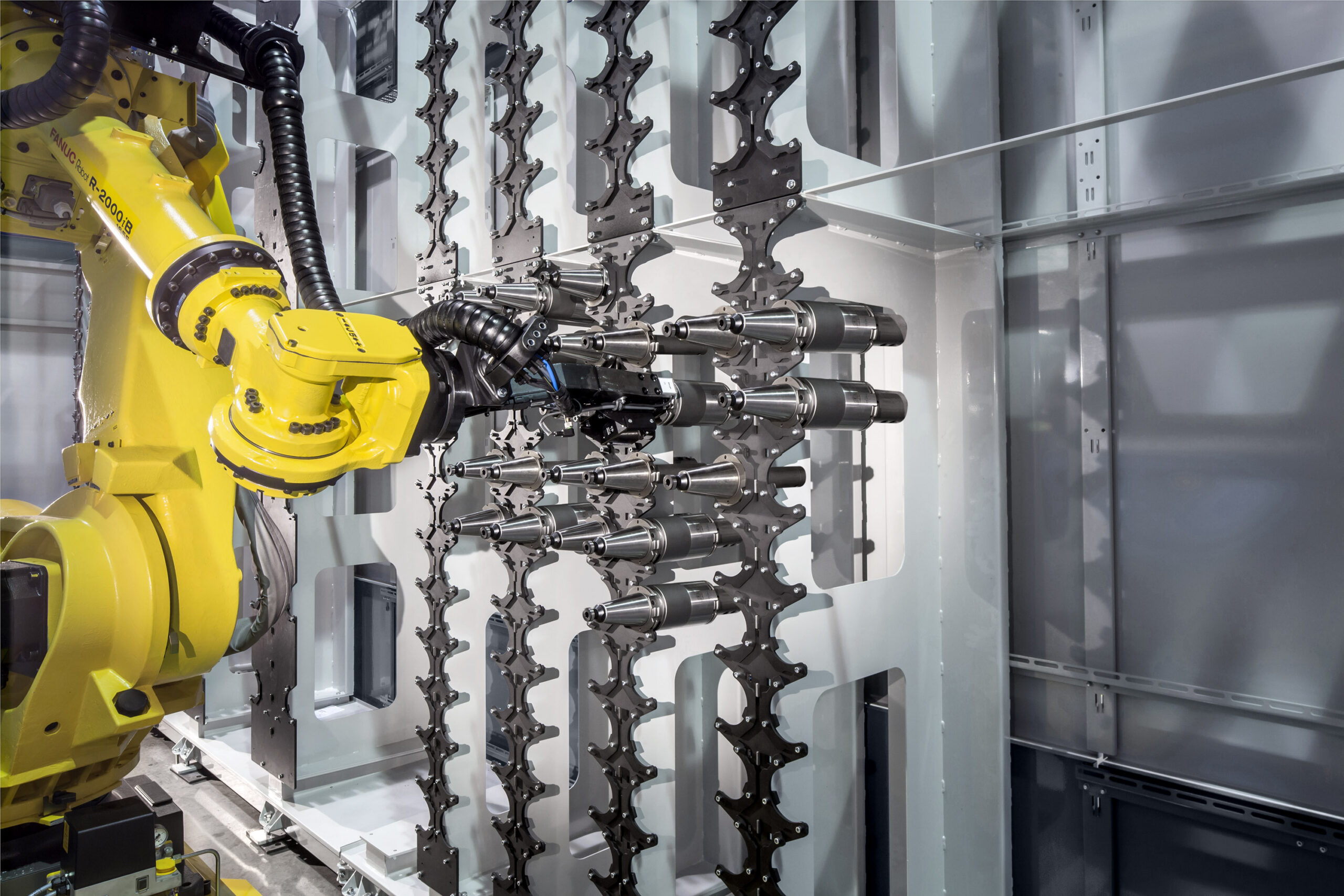

Tool Automation

Tool automation is the solution to eliminate the above inefficiencies – it stores large number of cutting tools centrally and transfers them to machining centers just in time. With tool automation, you can extend your lights-out machining capacity, secure tool availability, reduce errors, and minimize your capital investment in cutting tools and magazine pots.

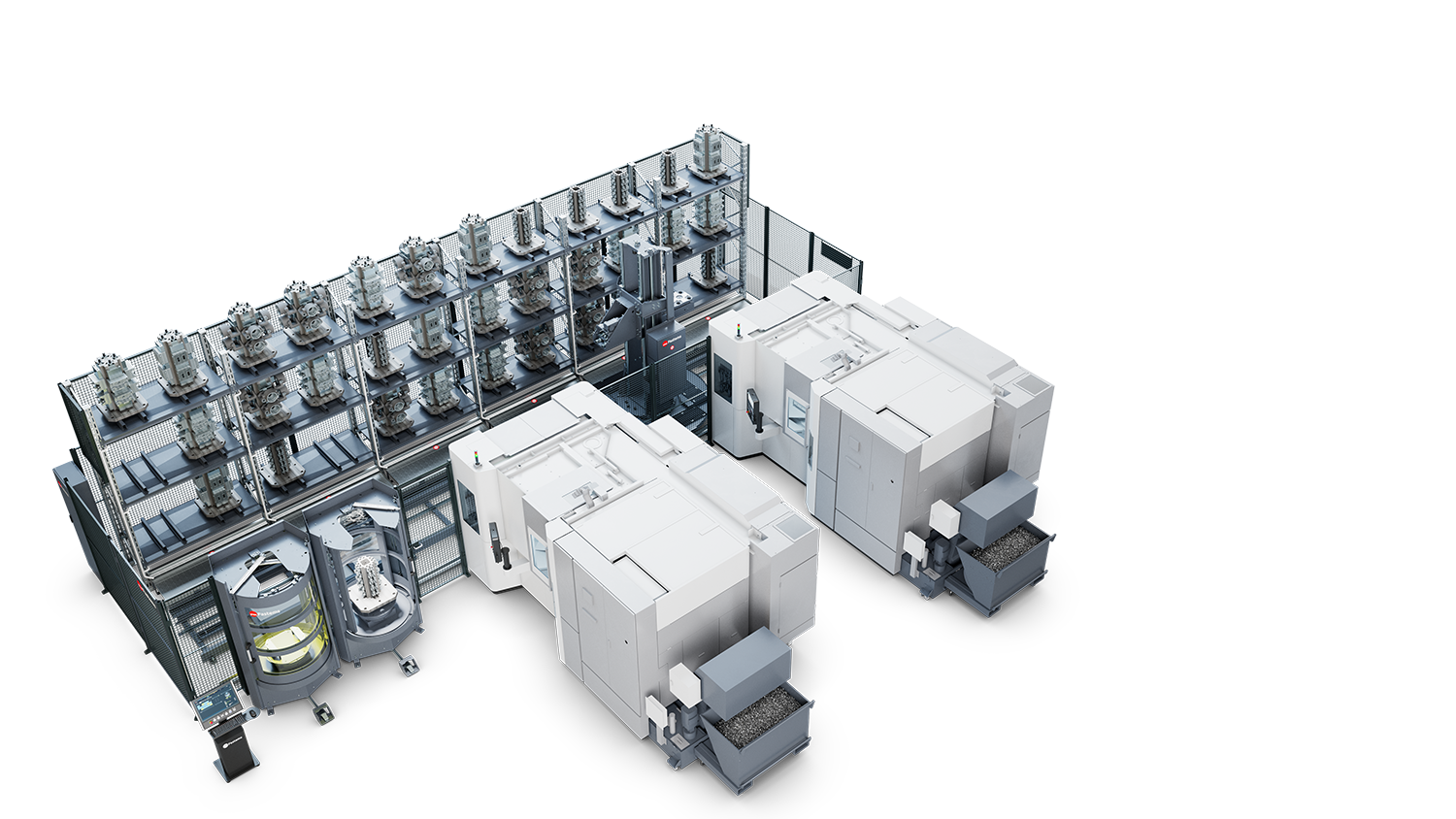

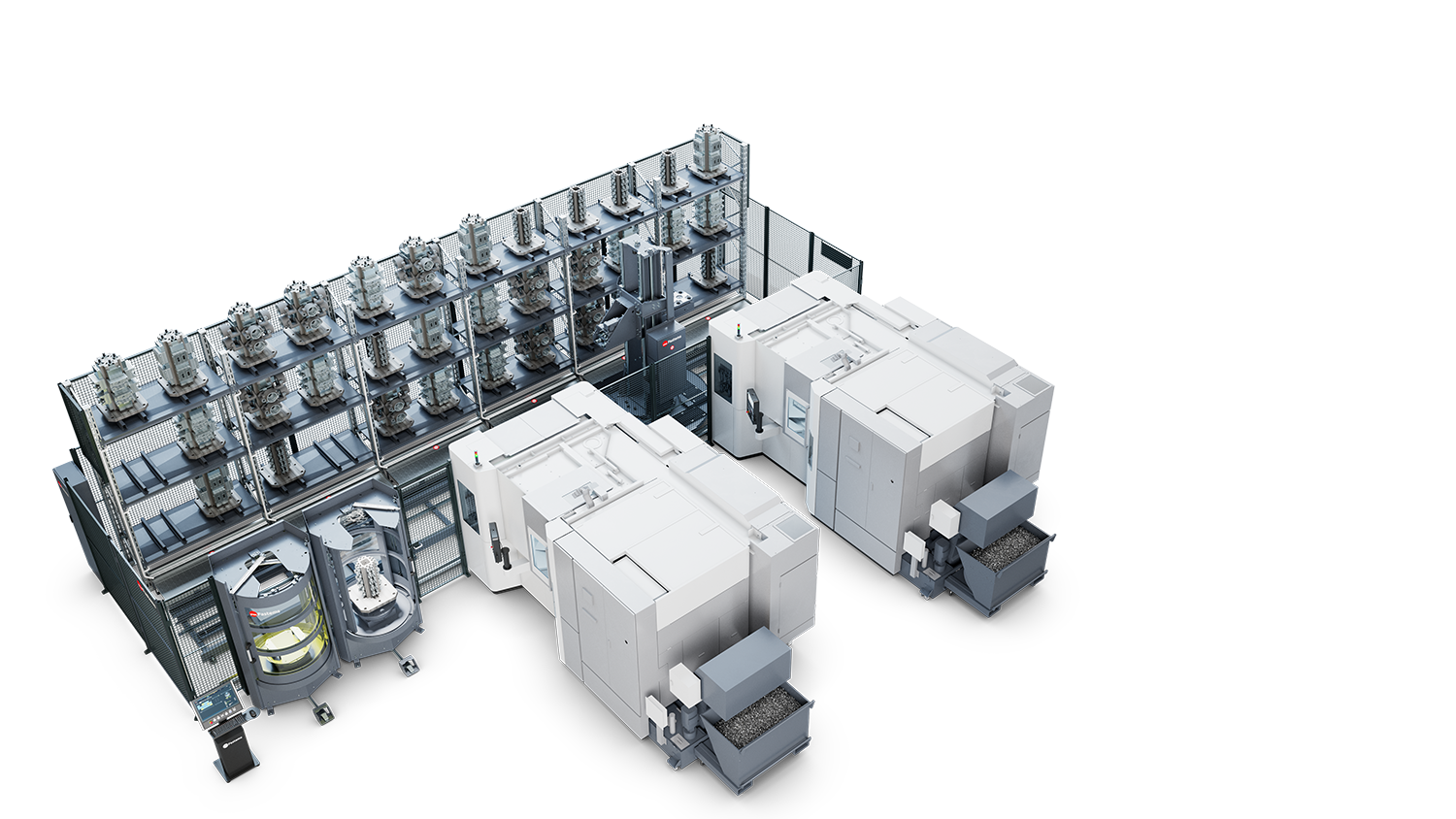

Flexible Pallet System (FPS) for 4 and 5 Axis Milling Machine

Ready to supercharge high-mix manufacturing with your 4 or 5 axis milling or mill-turn machine tools? Also without the automatic pallet changer? Meet Flexible Pallet System, the modular FMS for 300-630 mm pallets or zero-point plates. Its 360° layout ensures fit in any space, also low-ceiling facilities – and like all our flexible manufacturing systems, you can add more machine tools or storage later.

Multi-Level System (MLS) Automates Your Machining and More

Multi-Level System (MLS) is a Flexible Manufacturing System (FMS) that automates milling and turning machine tools from over 90 brands to manufacture your part mix efficiently. MLS accommodates machine pallets and raw material pallets from 400 to 1600 mm. It also integrates your selected value-adding processes such as finishing, washing, measuring - and is fully compatible with Fastems tool automation.

A wide range of configurable loading and material stations allow safe and ergonomic operation for your parts from 500 to 11,000 kgs (1,000 to 25,000 lbs).

MLS utilizes full module stack of the industry’s leading manufacturing control system, MMS, that is designed to plan, run and monitor high mix production.

Multi-Level System (MLS) Automates Your Machining and More

Multi-Level System (MLS) is a Flexible Manufacturing System (FMS) that automates milling and turning machine tools from over 90 brands to manufacture your part mix efficiently. MLS accommodates machine pallets and raw material pallets from 400 to 1600 mm. It also integrates your selected value-adding processes such as finishing, washing, measuring – and is fully compatible with Fastems tool automation.

Flexible Pallet System (FPS) for 4 and 5 Axis Milling Machine

Flexible Pallet System (FPS) enables lights-out manufacturing and high spindle utilization in high-mix production with 4 and 5 axis milling and mill-turn machines, also with compact vertical 5-axis machines. This modular CNC automation solution handles machining pallets and zero-point plates of 300-630 mm and its unique 360-degree design ensures a fit for any shop floor – including tight spaces and low-ceiling facilities. FPS can integrate CNCs of over 90 brands and be extended or upgraded if there is a change in production needs.

Unleash the Full Potential of Your Manufacturing With Fastems

Fastems' intelligent automation helps you to make your people, machinery and systems work as one. Learn more at www.fastems.com

No brochures provided.

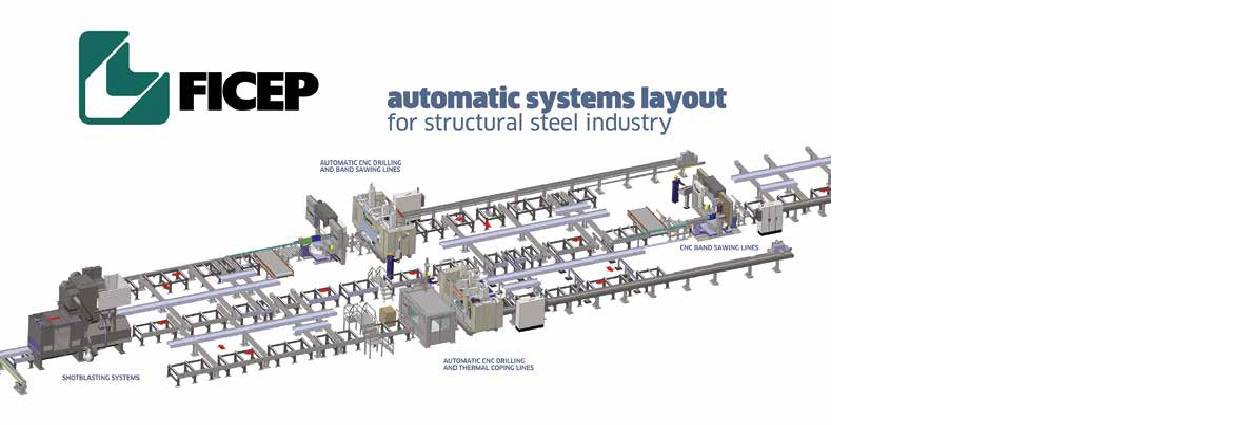

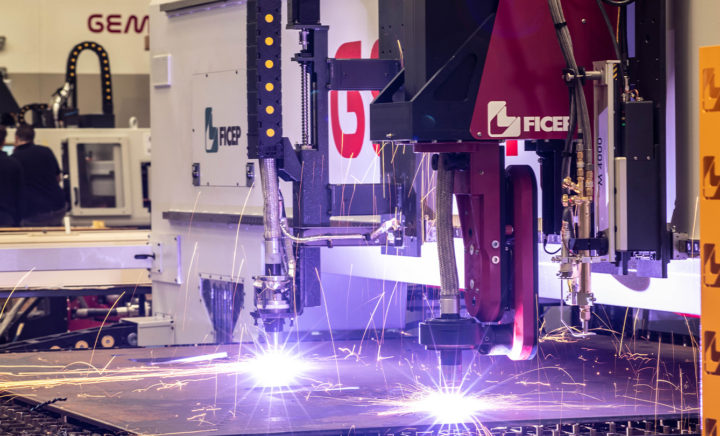

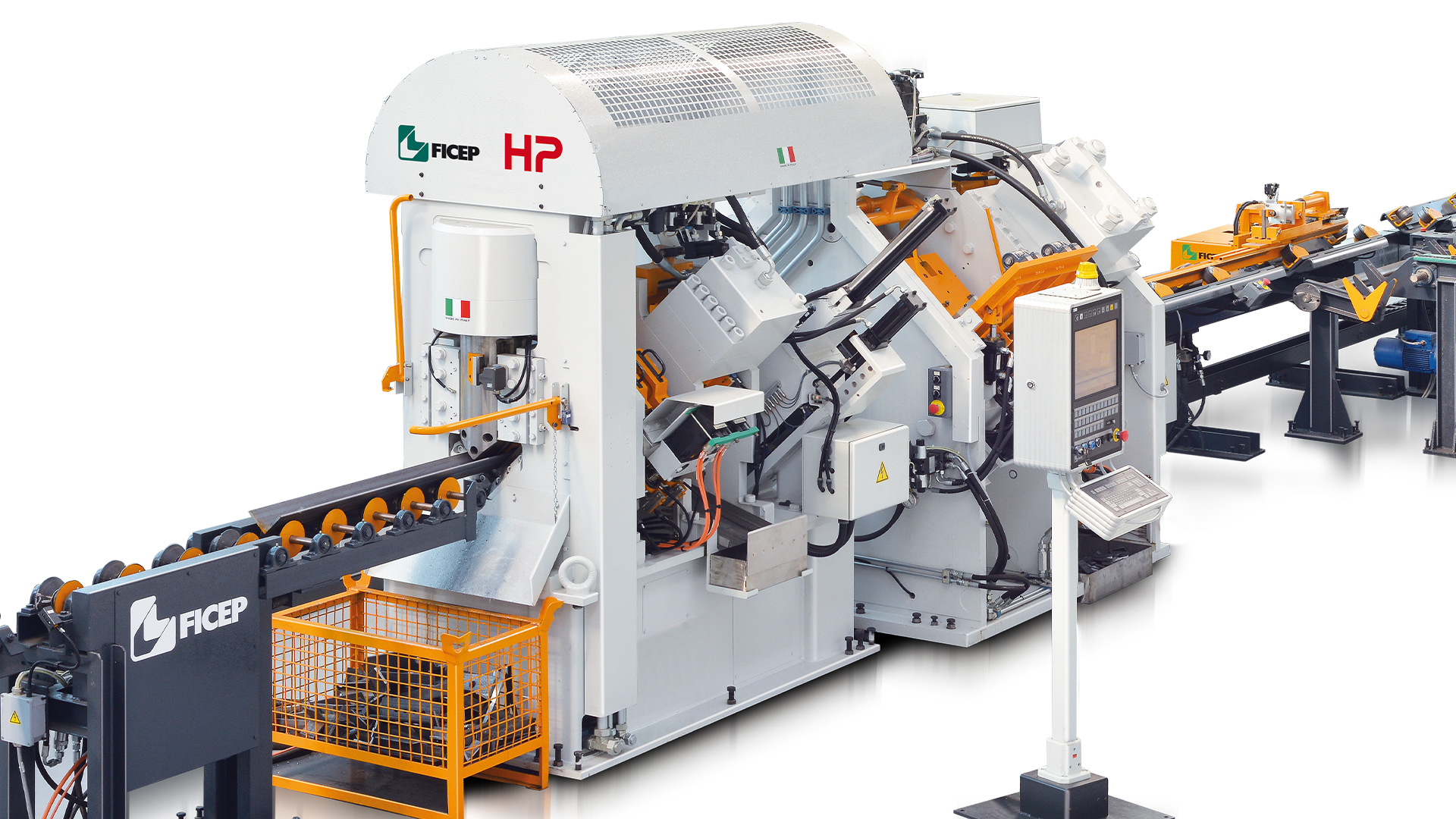

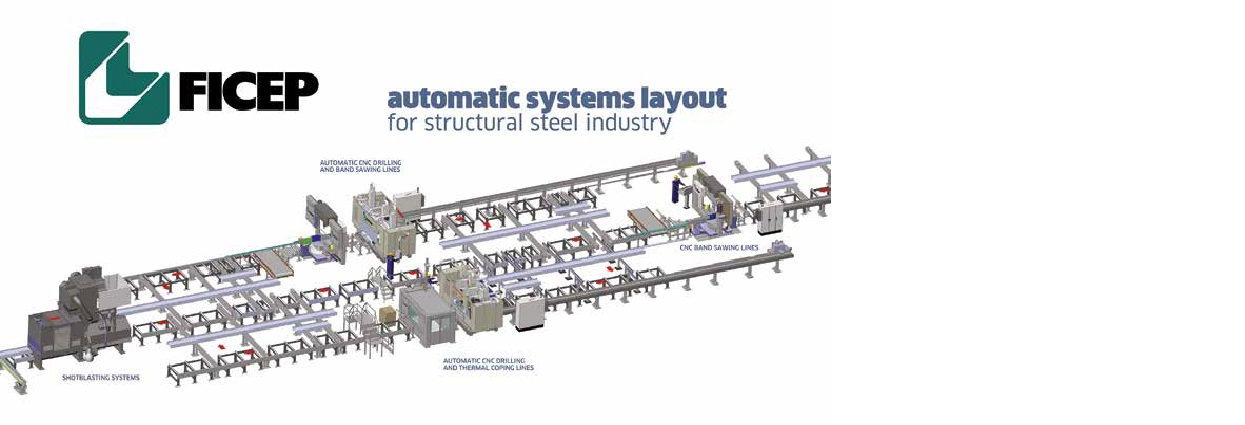

FICEP (UK) LIMITED

Stand: 6-330

FICEP (UK) LIMITED

Description

A leading supplier of structural steel and plate processing equipment - will showcase its latest technology and solutions for the steel fabrication industry. Ficep UK will demonstrate its automated CNC machines, drilling systems, and material handling equipment, plus its software to help improve manufacturing accuracy, efficiency and productivity.

Categories

Address

Unit 3 Gilcar WayWakefield Europort

Castlford

Wakefield

West Yorkshire

WF10 5QS United Kingdom

Customer Service

The secret of excellence, is the ability to maintain it over time. For our clients, after-sales service, training and technical assistance are at least as important as the products we produce in order to keep a high level of availability during the product life cycle.

Software

Software to interface design to machine process

Angle and Flat bar

Processing of Angle and Flat Bar

Plates

Processing of Plates

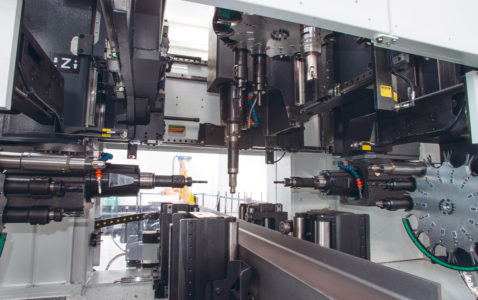

Beams

Processing of Beams

Ficep UK New at Mach 2024

Download

XBlade

Download

Surface Treatment

The need to satisfy today’s strict painting codes has pushed fabricators to introduce shotblasting as a requirement prior to painting.

Download

Customer Service

Download

Synthesis

Download

Angle and Flat bar

Download

Plates

Download

Beams

DownloadFILCOM GROUP

Stand: 6-449

FILCOM GROUP

Description

FILCOM have been in the filtration sector for over 25 years.

We manufacture and supply cost saving filter solutions compatible for use with various OIL MIST FILTRATION SYSTEMS.

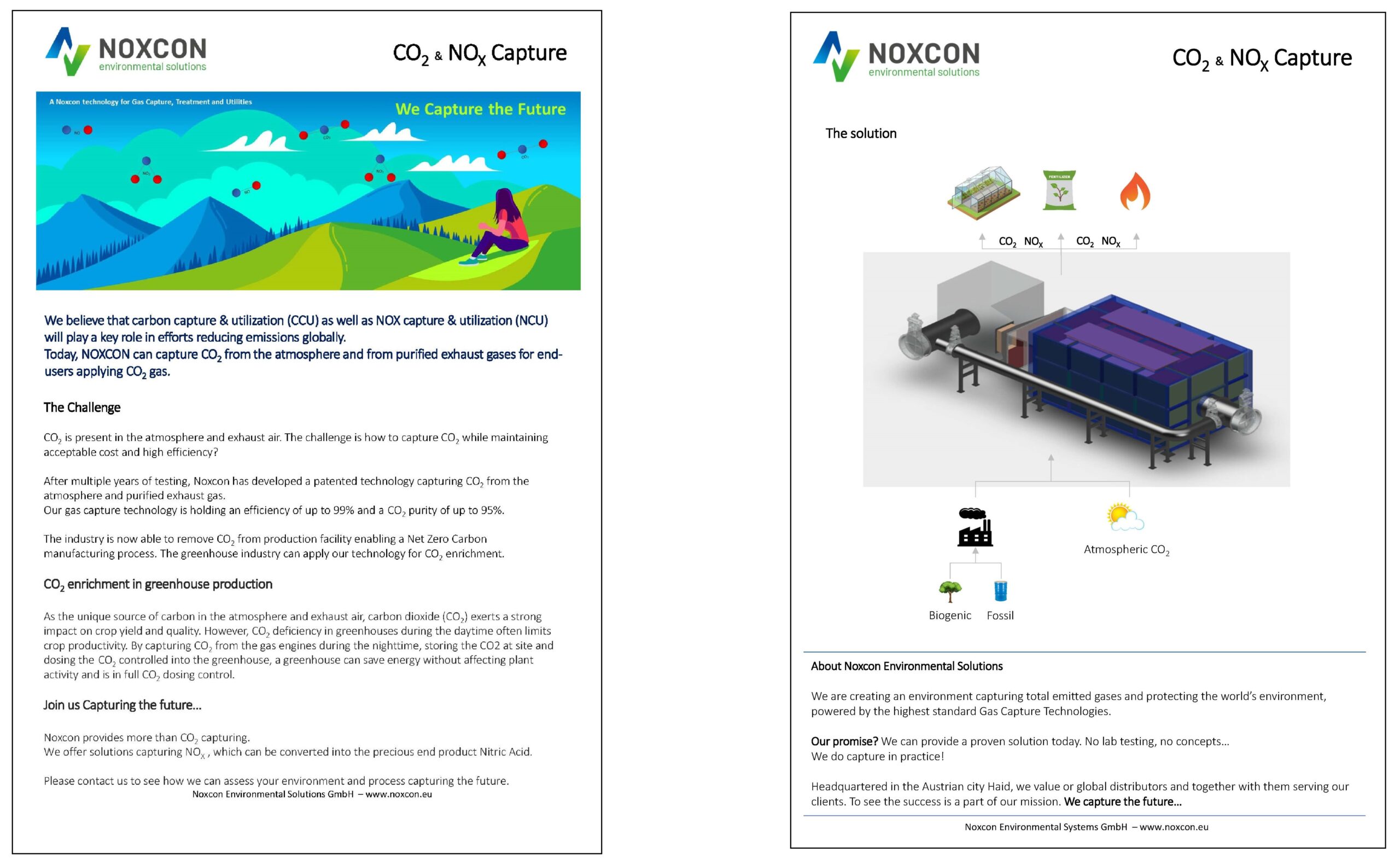

Our latest technology captures CO2 & NOx from manufacturing burning methods.

Categories

Address

Unit 16 Stirlin Point, Sadler Court, Sadler Road, LincolnSadler Court

Sadler Road

Lincoln

Lincolnshire

LN6 3RG United Kingdom

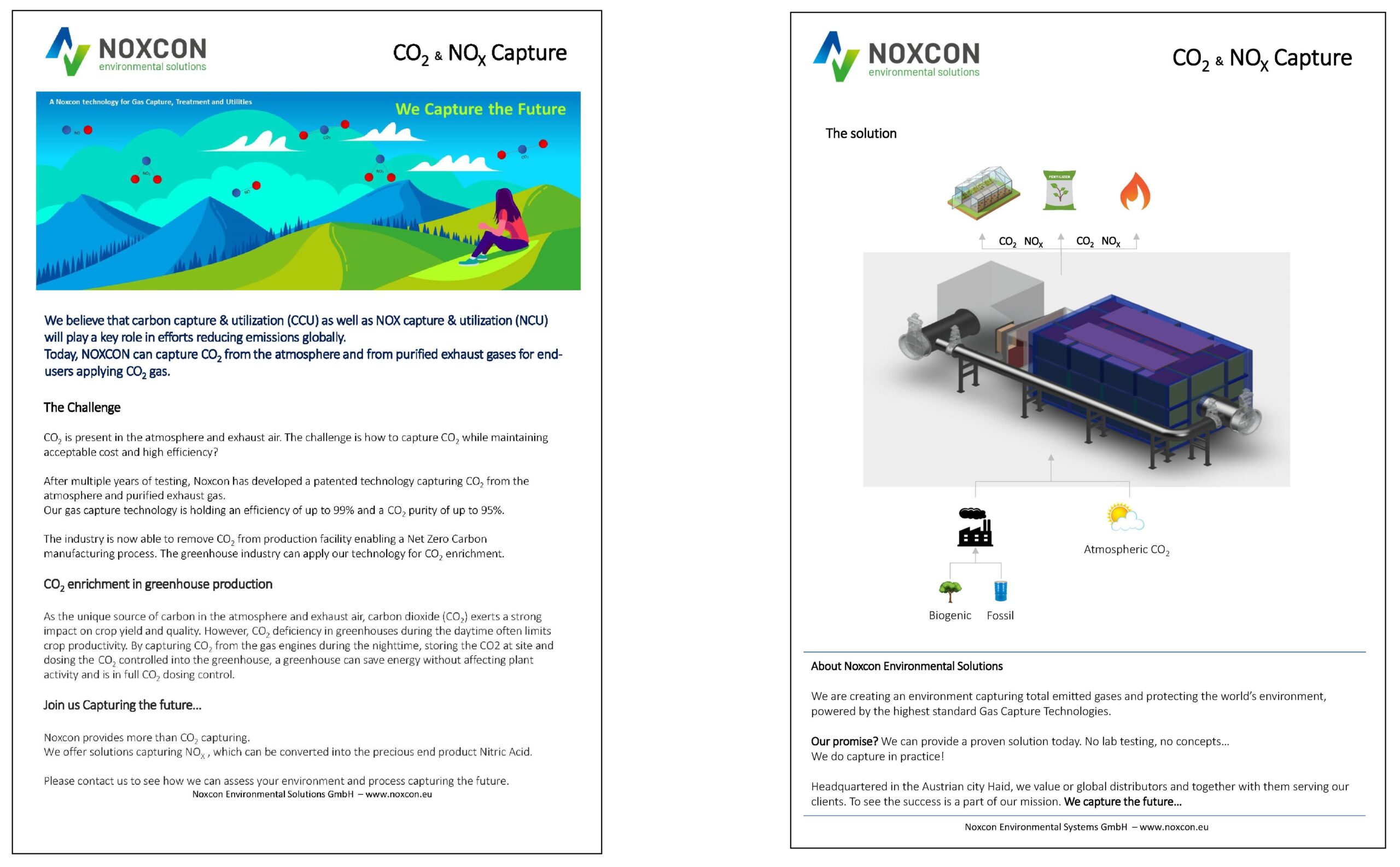

CO2/NOx Capture & Storage

CO2/NOx capturing and storage technology.

This technology is capable of capturing CO2 and NOx gases produced within many sectors.

CNC Oil Mist Cassette Filter

Quality Cassette Replacement Filters

Centrifugal CNC Oil Mist Filter

Quality Replacement Centrifugal Filters

Centrifugal & Cassette CNC Oil Mist Filters

Filcom manufacture high quality filters suitable for Centrifugal & Centralised oil mist collectors.

To see how competitive our filters are please feel free to contact us today, & make savings tomorrow.

[email protected] +44 1522 217 179

CO2/NOx Capture & Storage

DownloadFILTERMIST LIMITED

Stand: 19-418

FILTERMIST LIMITED

Description

Filtermist ensures UK manufacturers are compliant with COSHH Regulations. Established in 1969, Filtermist designs, manufactures and supplies LEV systems that prevent exposure to airborne contaminants including oil mist, oil smoke, dust and fume. Aftermarket services include Servicing and Maintenance, LEV Testing, Air Monitoring, and Filtration Spares and Consumables.

Categories

Address

Telford 54 Business ParkNedge Hill

Telford

Shropshire

TF3 3AL GB

Filtermist Oil Mist Filters

Filtermist’s UK manufactured oil mist filters are trusted by world-leading manufacturers to effectively remove oil and coolant mist, fume and steam from the air in machine shops in over 60 countries. Compact, lightweight and efficient to 99.95%, Filtermist units use centrifugal impaction to separate oil mist particles from contaminated air: a perforated drum with specially designed vanes rotates at high speed, drawing air from the machine tool enclosure into the filter unit at high velocity. Special drum pads assist the coalescing process and filter out stray solid particles. Liquid drains to a collection point for disposal or re-use, and clean air is exhausted back into the machine shop.

Dustcheck Wet Collector

Wet dust collectors are recommended for capturing solid particulate matter in machining applications using reactive white metals such as aluminium, titanium and magnesium etc. due to their highly volatile nature. They are also ideal for handling sticky particulates or dusts extracted with liquid moisture.

Manufactured by Filtermist in the UK, Dustcheck NonFlam wet collectors are available with airflows ranging from 500m– 10,000m³/h (0.14 m³/s -2.8 m³/s) and can be sited inside or outside. NonFlam wet collectors can also be supplied to meet ATEX zoning requirements.

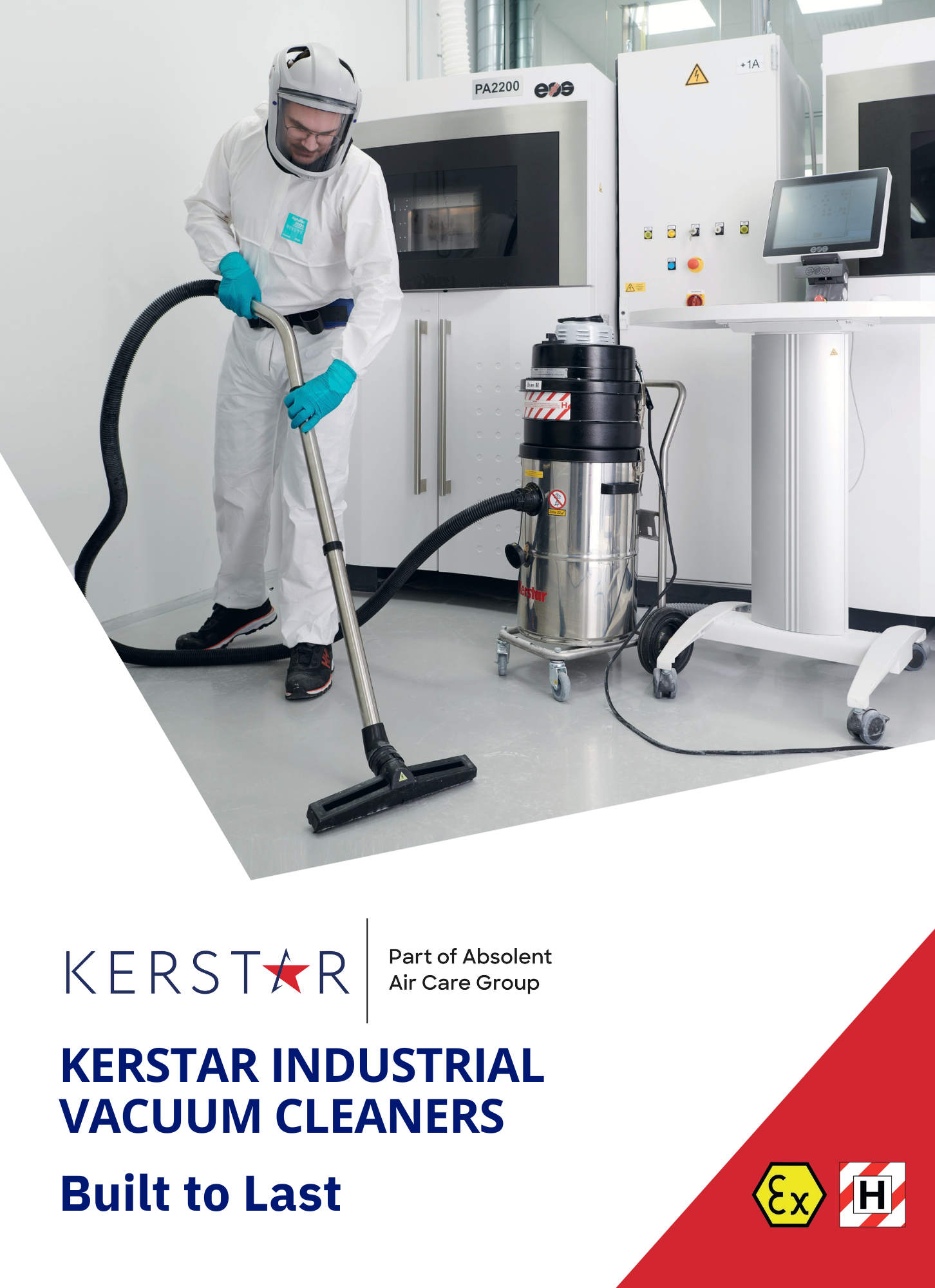

Kerstar KEVA ATEX Vacuum

Kerstar’s UK manufactured KEVA range has been purposely designed to pick up potentially explosive and conductive dust and debris in a Dust Zone 22. It is also suitable for picking up dust and debris that is hazardous to health in a Dust Zone 22. All models are built using an electronically commutated brushless motor featuring soft start and thermal protection.

Each model in the KEVA range is equipped with three stages of filtration on the negative pressure (suction) side of the motor. The final stage is a H14 HEPA filter.

Kerstar KEVA 20-45 Type H (ATEX Certified) Electric Vacuum Cleaner for Hazardous Dust

(ATEX Certified) Electric Vacuum Cleaner for Hazardous Dust

Filtermist oil mist collectors | Protecting People

Filtermist oil mist collectors | Protecting People

FINISHING AIDS AND TOOLS LIMITED

Stand: 6-579

FINISHING AIDS AND TOOLS LIMITED

Description

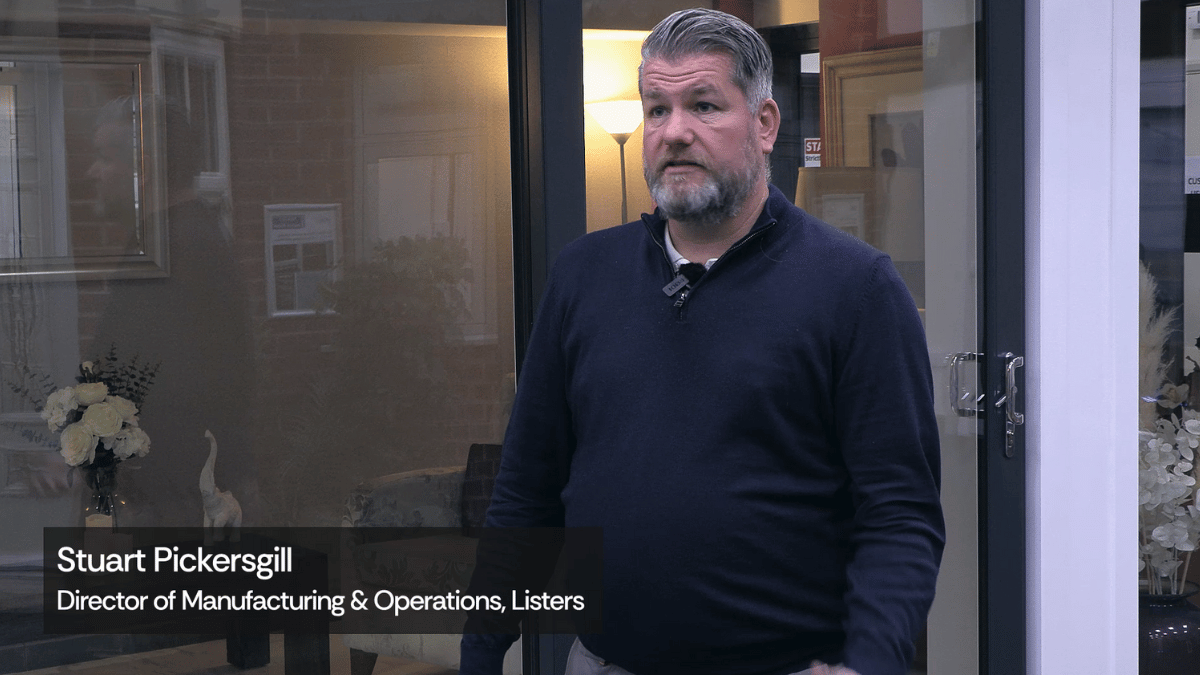

Finishing Aids and Tools Ltd is a supplier of surface finishing abrasives, tools and capital machinery including Lissmac, VG Machines and other sheet metal processing machines. FINAIDS is an abrasive converter capable of making belts, discs, lapmops. surface conditioning discs and other non-woven products in addition to a full coated abrasive manufacturing program including wide belts <1650mm.

Categories

Address

Little End Road Industrial EstateEaton Socon

Saint Neots

Cambridgeshire

PE19 8GF GB

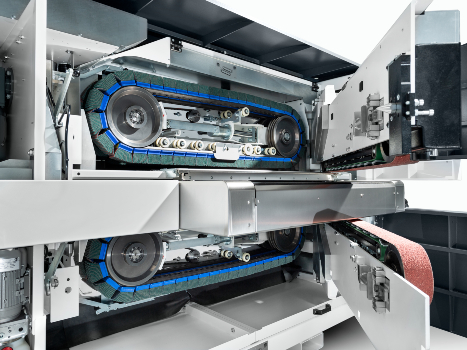

VG Machines CT650

The affordable CT 650 delivers metals up to 650 mm wide in their cleanest form. The controlled movement of the grinding belt ensures unprecedented reliability thanks to the electronic oscillation system. The integrated quick clamping system makes changing the grinding belt quick and easy. As a result, this economical machine offers you unrivalled finishing possibilities. This deburring machine is extremely suitable for deburring, rounding and finishing.

Kohler Part Levelling

The Peak Performer part leveling machine from KOHLER reliably and precisely levels and relieves stress from sheets and part blanks. Your downstream production processes benefit from higher quality leveled parts and sheets, as there’s no need for time-consuming, manual rework.

VG Machines C150

The VG Machines C150 range is available in multiple configurations to suit your current process. A grinding belt typically in the first position, this can be paired with either top-down deburring brushes, non-woven barrel brushes, coated abrasive orbital sanding heads or additional grinding belt heads to achieve a linear, grained or multi-directional finish. A wonderful machine suitable for small components, rectangular tubes and flat metal parts. Suitable for a wide range of materials: stainless and mild steel, aluminium, copper, brass and others.

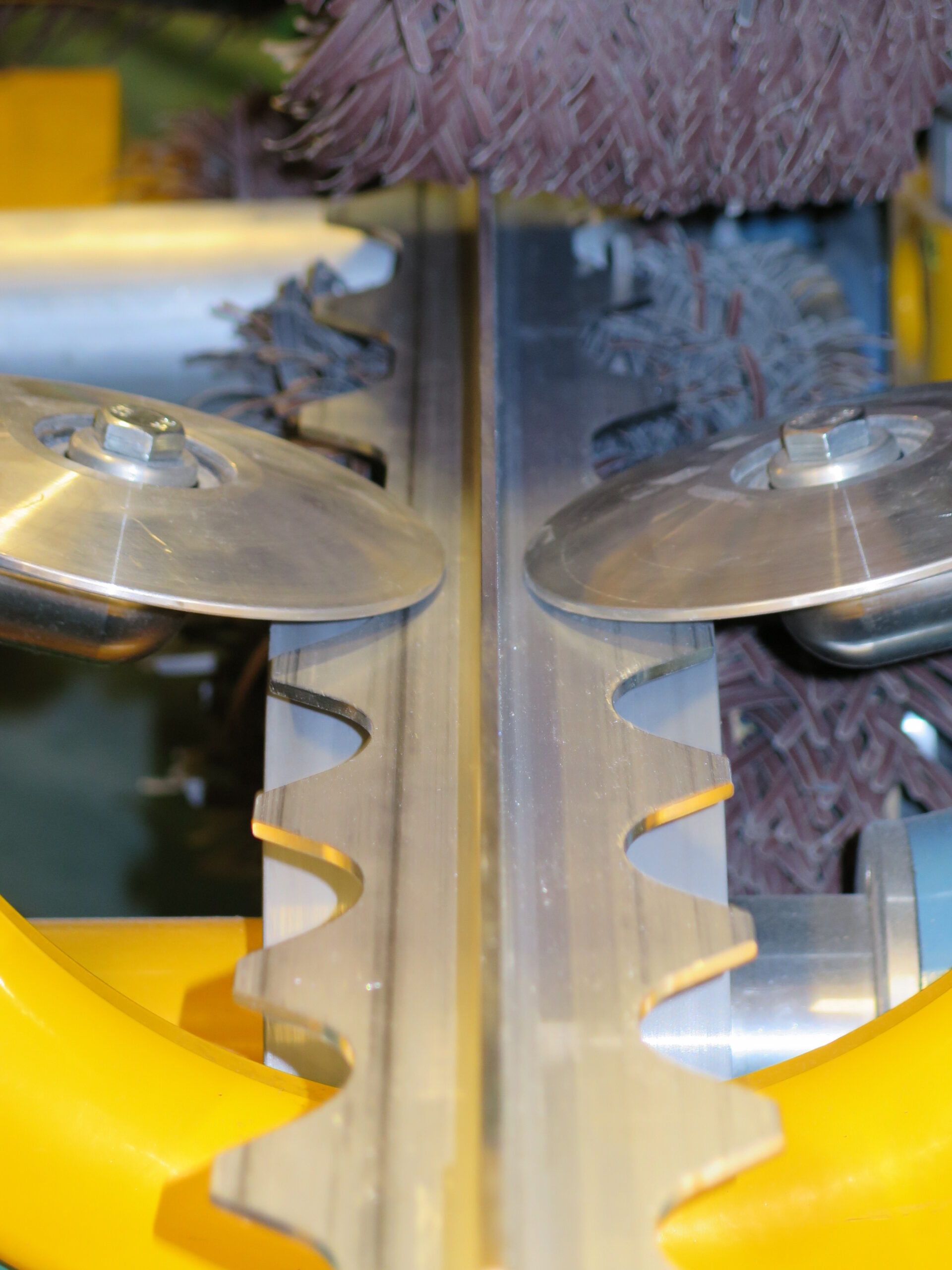

Lissmac SBM-L G1S2

The SBM-L G1S2 grinding and deburring machines were developed for deburring on both sides and edge rounding of workpieces in one operation. The LISSMAC machines are used for deburring sheet metal and processing sheet metal parts, laser parts and stamped parts. The L series is equipped with three units each on the top and bottom. The processing of stainless steel, steel, aluminium or non-ferrous metal workpieces can be done either on the upper side, the lower side or on both sides.

VG Disc Arm Grinder – FINAIDS Machinery

FINAIDS video detailing the features of the VG Machines Disc Arm Grinder 2.0

FINAIDS Product Catalog

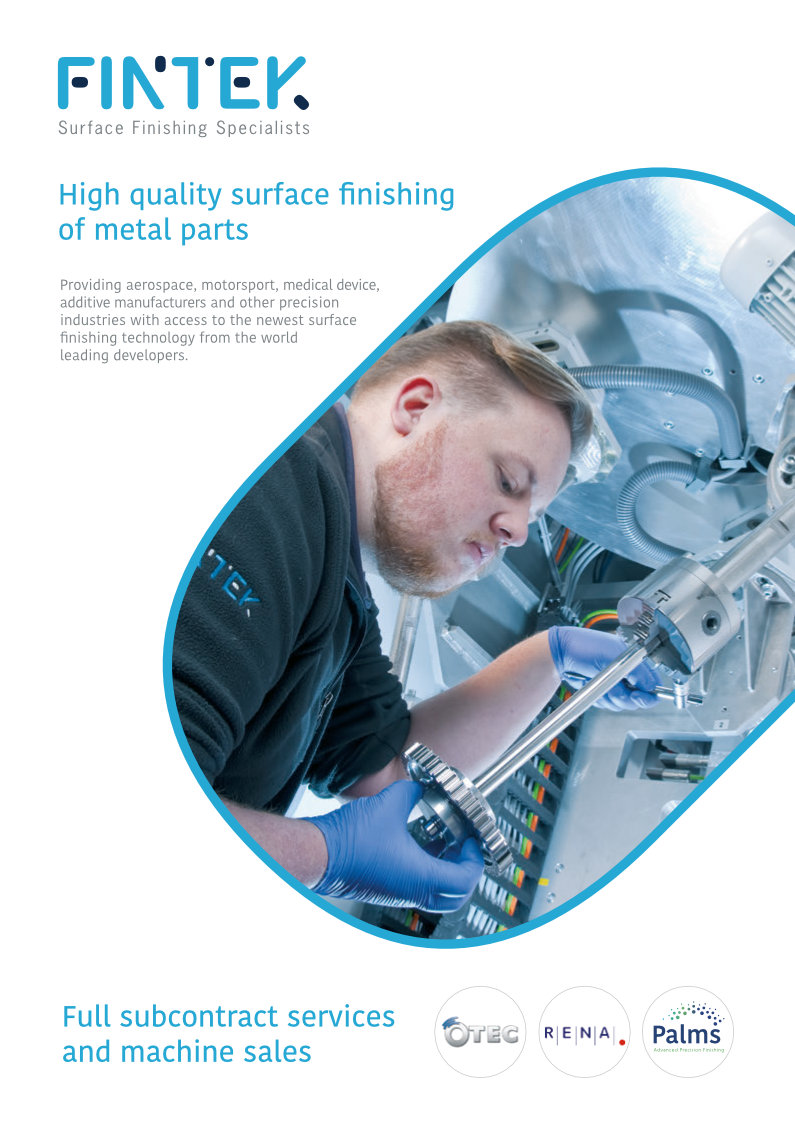

DownloadFINTEK

Stand: 18-12

FINTEK

Description

OTEC Präzisionsfinish disc, drag, stream & electro surface finishing machine sales for deburring, edge rounding, fine grinding, smoothing, superfinishing & polishing for CNC machined & 3D printed metal parts. Subcon services to engineers in aerospace, F1/motorsports, automotive, medical & more. Also Orbitool for deburring cross-drilled holes.

Categories

Address

Unit 1, Dean CourtHarvard Road

Bury

Lancashire

BL9 0GF GB

OTEC Präzisionsfinish Stream Finishing

Performance Superfinishing with Automatic Loading and Unloading

Exclusively available in the UK from Fintek, OTEC Präzisionsfinish stream finishing machines offer deburring, rounding and smoothing in a single, short processing cycle that does not compromise the dimensions or contours of the workpiece.

Workpieces, clamped in a holder are lowered into a rotating container of media. Path-controlled motion allows precise areas of a workpiece to be processed. Even difficult to reach regions such as small chip flutes can be targeted. Holders can be customised to meet any requirement. Fully automated loading systems are available to meet in-line production needs in automotive, aerospace and other precision industries.

OTEC’s patented pulse drive technology can be specified for SF units. Developed specifically for automotive and toolmaking customers, pulse finishing produces rapid relative motion between the media and workpiece by quickly changing the direction of rotation of the heads. High speed acceleration and deceleration increases the finishing forces exerted on the workpiece making it possible to deburr, round and smooth surfaces from Rpk 0.2µm to 0.1µm in under a minute.

OTEC Präzisionsfinish Drag Finishing

Perfect Results: High-Precision Edge Rounding, Smoothing and Mirror-like Finishing

Exclusively available in the UK from Fintek, OTEC Präzisionsfinish drag finishing machines give extremely high quality surface finishing in short process times.

Specially designed holders enable quick component mounting for productivity. These are then dragged in a circular motion through the process medium. Up to ten holders can be specified. Speed of rotation and angle of emersion in the media is finely controlled by and easy to use touch screen. The unique holders eliminate any possible contact between workpieces during the process cycle.

OTEC Präzisionsfinish Disc Finishing

Exclusively available in the UK from Fintek, OTEC Präzisionsfinish disc finishing machines offer reliable and repeatable high quality workpiece surface finishing. Using an open drum with a rotating base plate (disc), polishing and grinding media are set in motion to produce toroidal stream in which workpieces are added. The powerful centrifugal finishing forces between the media and workpieces are up to 20 times more effective than traditional methods.

Uniquely to OTEC machines, their zero-gap disc to drum technology allows extremely delicate and thin workpieces, with a sheet thickness of 0.08mm, to be processed.

From simple bench-top to multi-drum large capacity systems, Fintek can meet your surface finishing production needs. Machine sales and subcontract services available.

Fintek show how automated OTEC SF2 RLS stream finishing machines use robotic loading

An OTEC SF2 RLS stream finishing unit with robotic automation for loading and unloading. This brings surface finishing right into high speed production environments. In the UK and want to know more? We are exclusive UK agents for OTEC, call Fintek + 44 (0)1706 82 5819

Fintek Show How an Otec DF 5 Surface Finishes Femoral Components

Surface finishing specialist, Fintek show how using an Otec DF 5 for three processes - grinding, fine grinding and polishes leaves a perfect finish on femoral components for knee replacements. The company has a great depth of experience in medical device surface finishing. Want to know more call + 44 (0)1706 82 5819

Fintek show how an OTEC CF disc finishing machine processes small parts

Surface finishing specialist, Fintek show how using an Otec CF1x18 machine quickly improves the surface of small and thin metal parts.

Using an open drum with a rotating base plate (disc), polishing and grinding media are set in motion and to which workpieces are added. The powerful centrifugal finishing forces are up to 20 times more effective than traditional methods.

CF machines come in sizes ranging from desktop low capacity single drum to larger three drum floor standing machines for mass finishing in production environments. Want to know more? Call 01706 82 5819

Solving the Surface Finishing Problems of Industry

An overview of Fintek subcontract service finishing capabilities with images of finished parts. Providing aerospace, motor sport, medical device, additive manufacturers and other precision industries with access to the newest surface finishing technology from the world leading developers.

DownloadFIRETRACE LTD

Stand: 17-540

FIRETRACE LTD

Description

Firetrace Limited specialise in suppression systems using our unique, patented detection tube technology. Firetrace systems operate pneumatically & detect and extinguish fires at source without the need for external power. Firetrace is ideal for many applications and can easily be retrofitted to existing equipment.

Visit us to see the Firetrace tube in action.

Categories

Address

Unit 22Knightsdale Road

Ipswich

Suffolk

IP1 4JJ United Kingdom

Firetrace Indirect High Pressure CO2 Automatic Fire Suppression System

Firetrace Brochure

DownloadFLADDER DANMARK A/S

Stand: 6-369

FLADDER DANMARK A/S

Description

Fladder Danmark A/S manufacturer of the original patented FLADDER® finishing and deburring system offers manual and automatic machines and brushes worldwide. The FLADDER® trademark is synonymous with a perfect surface finish, deburring and a solid product. Machines are offered for various kind of sheet metal workpieces, machined and extruded parts.

Categories

Address

Groedevej 14Ansager

6823 DK

FLADDER® LS

FLADDER® LS is an automatic deburring machine for long 3-dimensional items, e.g. pipes, extruded profiles and especially for aero plane parts like stringers. FLADDER® LS is built of sections. One or two modules and a fixation unit are mounted in these sections. The sections of the machine are cylindrical. The benefit of this is that modules and fixation units can be mounted at any position desired. Each module consists of 2 powerful motors with 150-200 mm counter rotating Lock-It spindles each equipped with the flexible FLADDER® abrasive cylinders. Big tempered glass shields make it possible to watch the deburring process. The functions of each module - position and brush speed - can be adjusted individual either manually or through a program. The speed of the abrasive cylinders is controlled by frequency converters which minimize the power consumption. A touch screen operation panel makes it easy to operate the machine.

FLADDER® CC

FLADDER® CC is a compact machine with a footprint of only approx. 1.5 m2. It is easy to move if needed as it does not need neither foundation nor to be fixed to the floor.

Easy to get started: Just plug in to the power and the dust collecting unit. Ready to go!

The FLADDER® CC is built with a lower and upper cylindrical section.

Between these sections a circular vacuum table is rotating allowing workpieces to be fed manually or automatically.

For the operator the process is obviously an advantage: The functions of loading and unloading the machine is at the same position. It saves time and increases the efficiency.

Like our GYRO series this machine has a strong vacuum system for fixation of the workpieces. In fact the vacuum is stronger and activated by a new vacuum valve system.

The operation of the machine is very easy: A control panel is within reach for fast and easy adjusting of the functions and with a touchscreen.

A big sliding glass door combined with a strong internal flood light gives the operator full supervision of the process.

The deburring is a dry process.

As the functions in the machine are controlled by means of frequency converters the power consumption is low.

Perfect working conditions as the noise level is very low.

FLADDER® 200/GYRO-1000 VAC

FLADDER® 200/GYRO for multiple purposes: traditional deburring with abrasive brushes and removal of oxides using spring threaded cylinders. The power consumption of the machine is reduced by use of frequency converters as well as an energy saving system that automatically shuts down the machine when not in use. An efficient vacuum unit ensures a safe fixation of work pieces. The central gearhead allows the use of the larger brush dia. 400 mm where the customer will benefit of increased oscillation of the gearhead and 40% more deburring effect. A touchscreen makes operation of the machine easy.

FLADDER® LS

FLADDER® LS is an automatic deburring machine for long 3-dimensional items, e.g. pipes, extruded profiles and especially for aero plane parts like stringers. FLADDER® LS is built of sections. One or two modules and a fixation unit are mounted in these sections. The sections of the machine are cylindrical. The benefit of this is that modules and fixation units can be mounted at any position desired. Each module consists of 2 powerful motors with 150-200 mm counter rotating Lock-It spindles each equipped with the flexible FLADDER® abrasive cylinders. Big tempered glass shields make it possible to watch the deburring process. The functions of each module - position and brush speed - can be adjusted individual either manually or through a program. The speed of the abrasive cylinders is controlled by frequency converters which minimize the power consumption. A touch screen operation panel makes it easy to operate the machine.

FLADDER® CC

FLADDER® CC is a compact machine for dry deburring of small work pieces.

FLADDER® 200/GYRO-1000 VAC

FLADDER® 200/GYRO - an automatic machine for deburring and edge rounding and surface finish of metal and plastic parts.

For laser cut or punched sheet metal with different shape and size.

For different material like mild steel, stainless steel even with protective foil, galvanized parts, floor plates etc.

FLADDER® LS

FLADDER® LS is an automatic deburring machine for long 3-dimensional items, e.g. pipes, extruded profiles and for aero plane parts like stringers. FLADDER® LS is built of cylindrical sections containing one or two modules and a fixation unit. Big tempered glass shields make it possible to watch the deburring process.

A touch screen operation panel makes it easy to operate the machine.

FLADDER® CC

FLADDER® CC - is a small automatic footprint machine for brush finish, deburring and denibbing of small workpieces.

Download

FLADDER® GYRO machines

FLADDER® GYRO - automatic machines for brush finish, deburring and denibbing. A powerful and efficient machine concept.

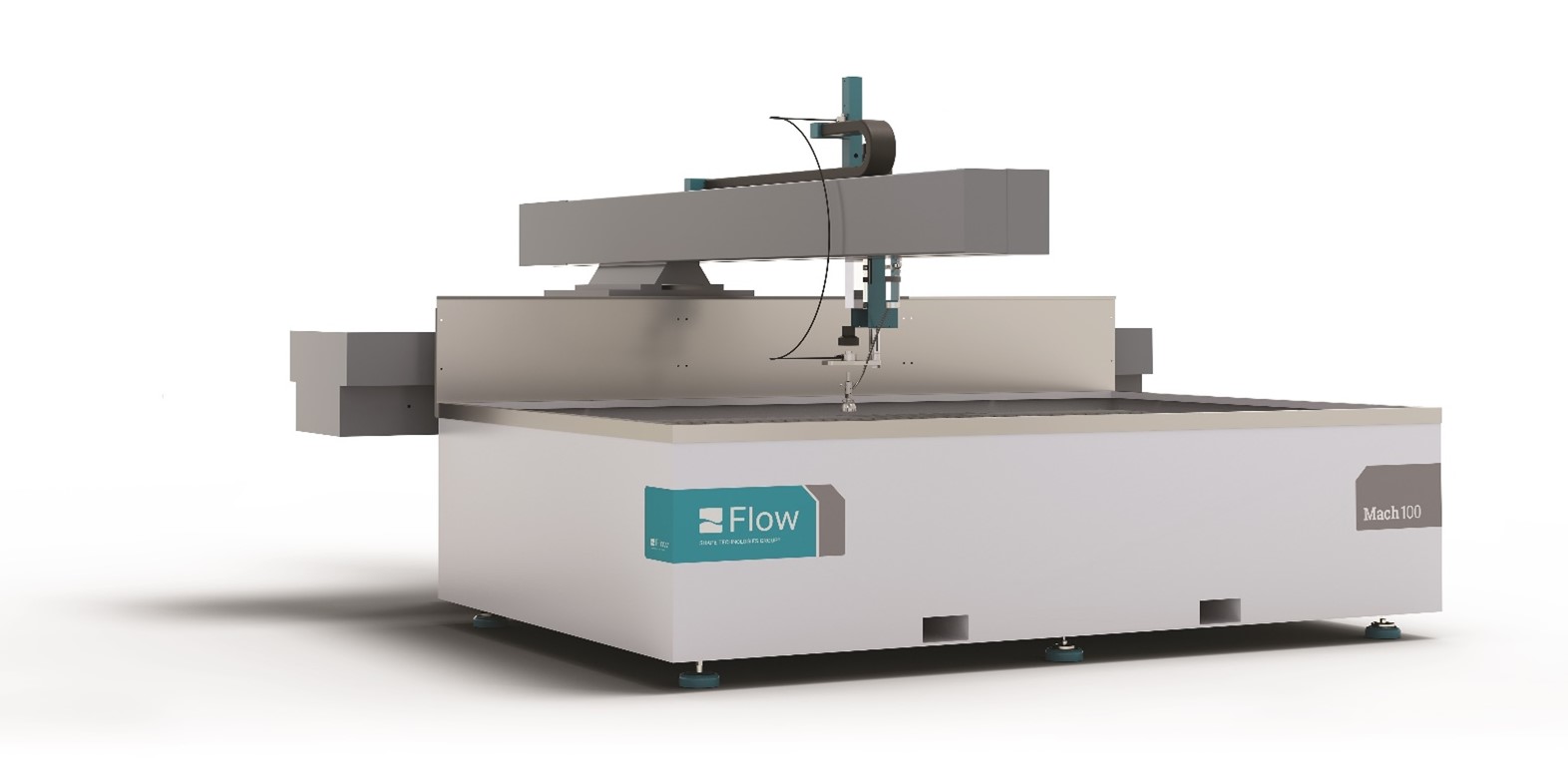

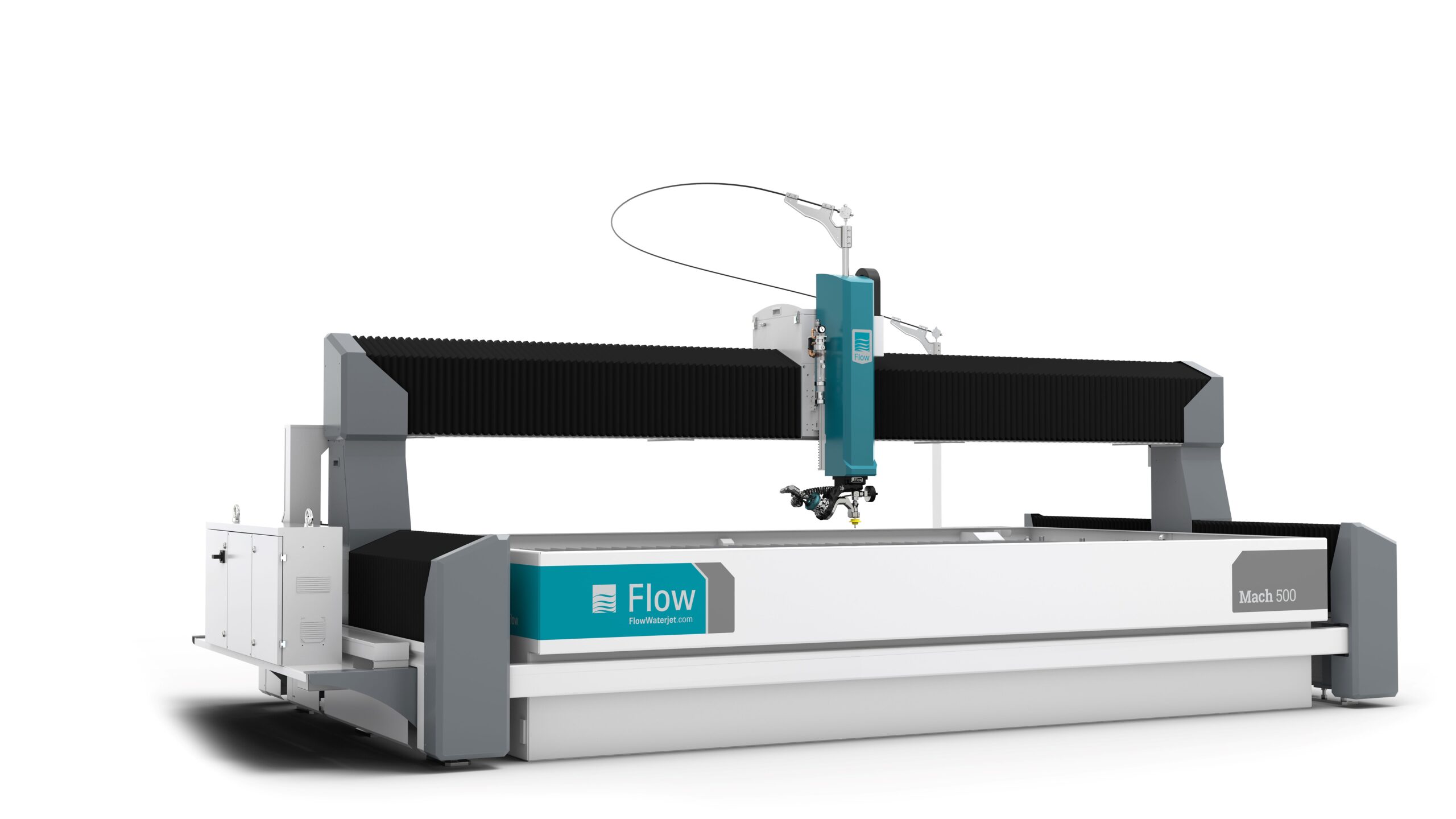

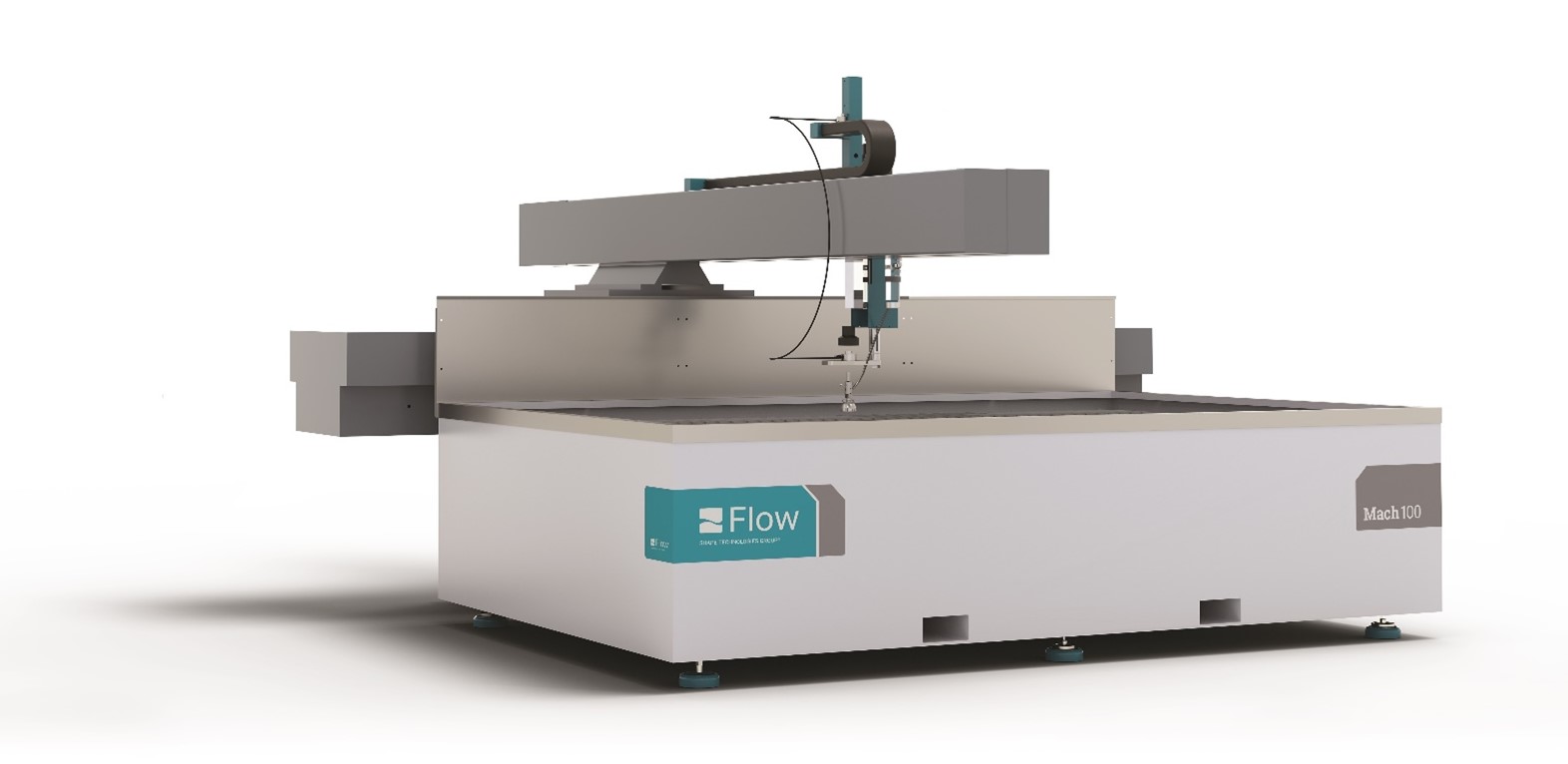

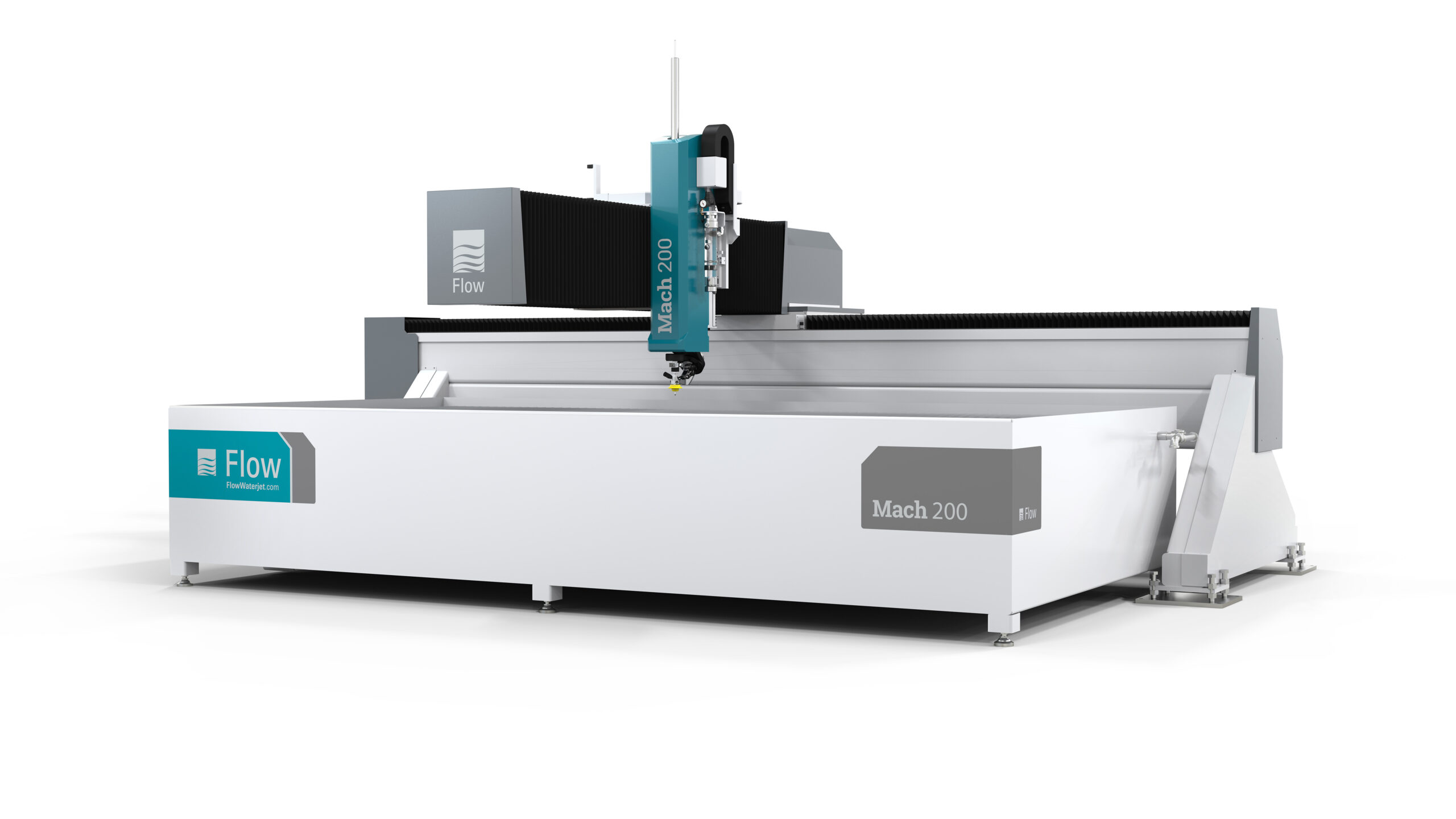

DownloadFLOW WATERJET

Stand: 6-360

FLOW WATERJET

Description