For the big jobs, the EROWA Giant Tooling System measures up

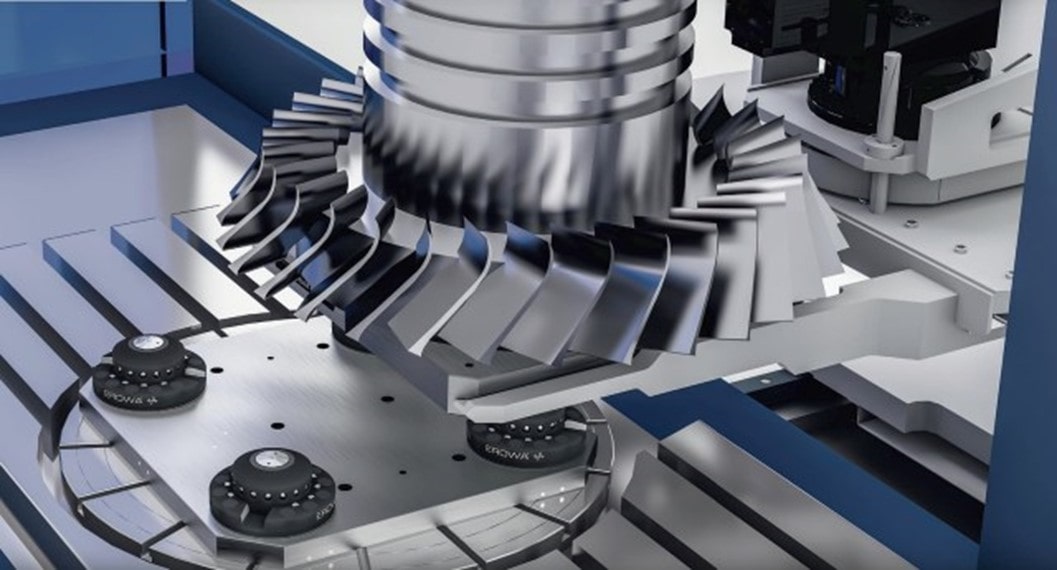

The ‘Giant Tooling System‘ (GTS) is the new, automation-ready tooling system innovation from EROWA. Available in the UK from the Swiss company’s established partner, REM Systems. The patented system has been conceptualised to clamp large and heavy workpieces.

Besides its use in rough machining, the tooling system is particularly suitable for chip removal applications such as milling and turning. The GTS can be mounted on every machine table and provides optimal machining performance, the highest degree of precision and uncompromising monitoring functions.

As Managing Director, Ian Holbeche, explains: “Every business manufacturing large components faces the same challenges regarding workshop efficiency and productivity as those producing parts up to a manageable 20 kg or so, but with the additional problems associated with the hefty weight of the workpiece. When we manually load a manageable component into a machine vice we may achieve the final alignment with the aid of a soft faced mallet. That certainly will not work on a large part.

“This is where the new ‘Giant Tooling System‘ from EROWA can help. The tapered faces on the system help guide the workpiece accurately to the desired location before it is securely clamped ready for machining.”

With a clamping power of 80 kN force per chunk, the Giant Tooling System provides a stable and immovable machine table base. The number of chucks can be specified to suit the exact customer requirements The clamping status of the chuck and the workpiece is monitored by the hydraulic closed and open check with guaranteed reliably. Additionally, the tooling system possesses a pneumatic cleaning function that protects all the relevant precision and functional areas against swarf and coolant ingress and contamination.

One significant feature of the EROWA Giant Tooling System is the ‘Floating’ clamping part. This unique aspect provides thermal compensation, thereby ensuring consistent quality and precision even in harsh conditions with fluctuating temperatures, such as those in the working envelope found during the machining process.

Additionally, a lowering and raising function that is integrated in the chuck aids the loading and unloading process of pallets and workpieces that is easier on the system. Besides its manual application, the EROWA GTS can be fully automated with process reliability thanks to its extensive functions. The EROWA Giant Tooling System is the ultimate solution for companies that need to efficiently machine large and heavy workpieces to high quality standards and tight tolerances. With a robust design and technologically advanced capabilities, it is the best choice for demanding production environments.

Ian Holbeche concludes: “While GTS will certainly improve the Overall Equipment Efficiency (OEE) for any machine shop manually loading mid to large and even very large workpieces, it is the systems ability to support automation that will make the largest impact on any Key Performance Indicators (KPIs). The capability to confirm chuck status being vital to any process monitoring hierarchy and the self-cleaning function ensure process reliability.”

Visit EROWA on Stand 20-362