Cooperation between the CHIRON Group and MAPAL in the USA

In a factory in Charlotte, North Carolina, CHIRON America Inc. assembles turnkey solutions based on standard machines supplied by their German parent company in Tuttlingen. These solutions are customised to meet the specific needs of their customers. Once again, MAPAL was selected as partner and tool supplier for a CHIRON machine used in truck parts production.

Customer proximity is key

CHIRON Group has been active in the United States since 1993, with a modern factory opening in Charlotte in 2001. The 7,000-square-meter plant employs 100 employees focused on adapting German-built machines to meet the needs of the American industry. From fine-tuning hydraulic systems to developing advanced automation and turnkey solutions, the focus is on delivering precision and efficiency. These machines are designed for efficient production of specific components and are delivered to customers fully equipped with software, clamping fixtures, and tools—ready for immediate operation.

Like CHIRON Group, MAPAL also operates in the United States with two sites located in Port Huron, Michigan, and Fountain Inn, South Carolina. The precision tool makers and technology partners from Aalen/Germany recognised at an early stage that customer proximity was essential in the American market. This insight led to the establishment of MAPAL’s first international subsidiary in 1977. It began in New Jersey with the reconditioning of MAPAL tools. As MAPAL expanded into the automotive industry in the following years, business grew significantly. It soon became clear that the small factory was no longer sufficient. The next logical step involved setting up a manufacturing site closer to key automotive customers. MAPAL opened its production site in Port Huron in 1995 with a focus on manufacturing and reconditioning of high-precision tooling, such as reamers with guide pads. Through its proximity to Detroit, the company was able to provide faster response times and comprehensive technical support to customers.

By consolidating technical knowledge within its international Centres of Competence, MAPAL expanded its know-how and expertise in the manufacturing sector. In 2019, the precision tool maker expanded further by opening a second factory in the southern region. The Fountain Inn site enhanced sales, service, and manufacturing capabilities, complemented by a state-of-the-art aerospace test centre. Today, MAPAL Inc. manufactures solid carbide and PCD tools at both sites using technology and processes that adhere to the MAPAL Group’s global standards. The tools include drills with one or more diameters, form cutters, reamers, and tools for composite machining – all of which are also reconditioned in-house.

CHIRON Group and MAPAL have been cooperating in North America for nearly as long as the machine tool builder has been present in the region. As a trusted OEM supplier, MAPAL has supported CHIRON Group’s work across the automotive, aerospace, and medical technology industries, as well as their suppliers. “To offer our customers the best solutions, we need reliable partners – a quality MAPAL has consistently demonstrated,” says Jesus Flores, Lead Project Engineer at CHIRON Group in Charlotte.

Demanding components

This highly complex component with many bores and a complicated form is machined out of aluminium A380 die-casting alloy. The customer aims to produce 120,000 units per year. With a potential production run of six to eight years, the total number of units could reach a million before a design modification may occur.

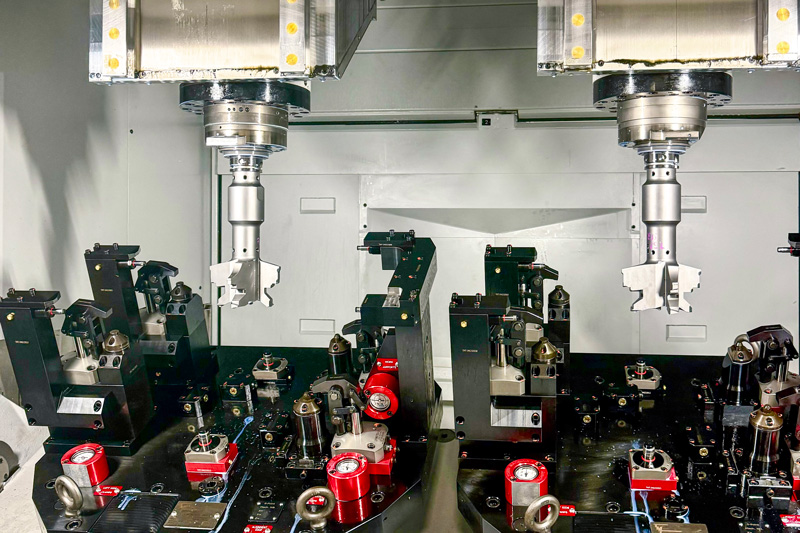

Efficient manufacturing is key to produce the required production volume of transmission housings. The double-spindle machining centre DZ 25 P five axis has been selected for this task, which CHIRON Group has developed especially for the productive machining of components with large volumes. Its rigid structure allows for high axis acceleration and rapid traverse speeds, ensuring dynamic and precise machining.

In the spacious working area, the machine can process two 800 x 800 mm components simultaneously. In the first step, the workpiece is clamped in its delivered state in order to perform pre-machining, which helps release internal stresses within the component. At the same time, machining with midrange tolerance requirements takes place. The precision machining of fitting bores and surfaces relative to reference points happens in a subsequent clamping step.

Two-thirds custom tools

Whenever possible, multiple machining steps have been combined into a single tool, allowing the machining of various diameters in one operation. “Cycle times are reduced with these custom tools”, explains Jesus Flores. “In this way, we save multiple tool changes every time, which improves both the machining times and precision.” Besides speed, the components require a high level of precision and quality that surpass typical automotive industry standards.

When it comes to positioning accuracy, a tolerance of 25 µm has been prescribed for diameter tolerances ranging from 8 to 10 µm. “This component has some of the highest quality requirements that I’ve ever seen. That’s a challenge for a workpiece of this size”, says Flores. The combination of cutting-edge machines and high-performance MAPAL tools has made the project a success. CHIRON Group highlights the quality of the PCD tools in particular, which are ideal for long production runs due to their extreme resilience and hardness.