Don’t Miss Your Opportunity to Have Your Tooling Challenges Resolved by Experts at the MACH 2022 Tooling Clinic

/Visitors to MACH 2022 are being offered the unique opportunity to have their tooling challenges resolved free-of-charge by a team of expert – and independent – tooling specialists.

Read more

HMV Catapult Trail returns for MACH 2022

/The strong focus on the future of manufacturing technologies will be highlighted at MACH 2022 by the return of the popular High Value Manufacturing (HVM) Catapult Trail. The HMV Catapult is the go-to place for manufacturing technologies in the UK, supporting organisations of all sizes in their success. The Catapult Trail, consisting of four stands […]

Read more

MACH 2022 to focus on the ability of Additive Manufacturing to ‘rocket boost’ productivity

/The ability of Additive Manufacturing to be a significant disruptive technology for UK manufacturers will receive a special focus at MACH 2022. The focus will be underpinned by the relaunch of the only UK trade association dedicated to the sector, AM-UK. AM-UK is designed for companies who work with Additive and 3D printing technology – […]

Read more

MACH 2022 Education & Development Zone targets next generation engineers

/As with previous MACH exhibitions, MACH 2022 will have a strong focus on encouraging more young people into the engineering and manufacturing technologies industry. Focus of this will the Education & Development Zone, which will feature special displays and a dedicated exhibition zone showcasing the changes taking place within manufacturing and highlighting what makes it […]

Read more

Accelerate investment in UK manufacturing at MACH 2022

/For manufacturers and engineers looking to invest for growth, the arrival of MACH 2022 could not be timelier. The exhibition, which opens its doors at the NEC in Birmingham between 4-8th April, features the largest display of new machinery and manufacturing technologies under one roof in the UK for four years. The Manufacturing Technologies Association […]

Read more

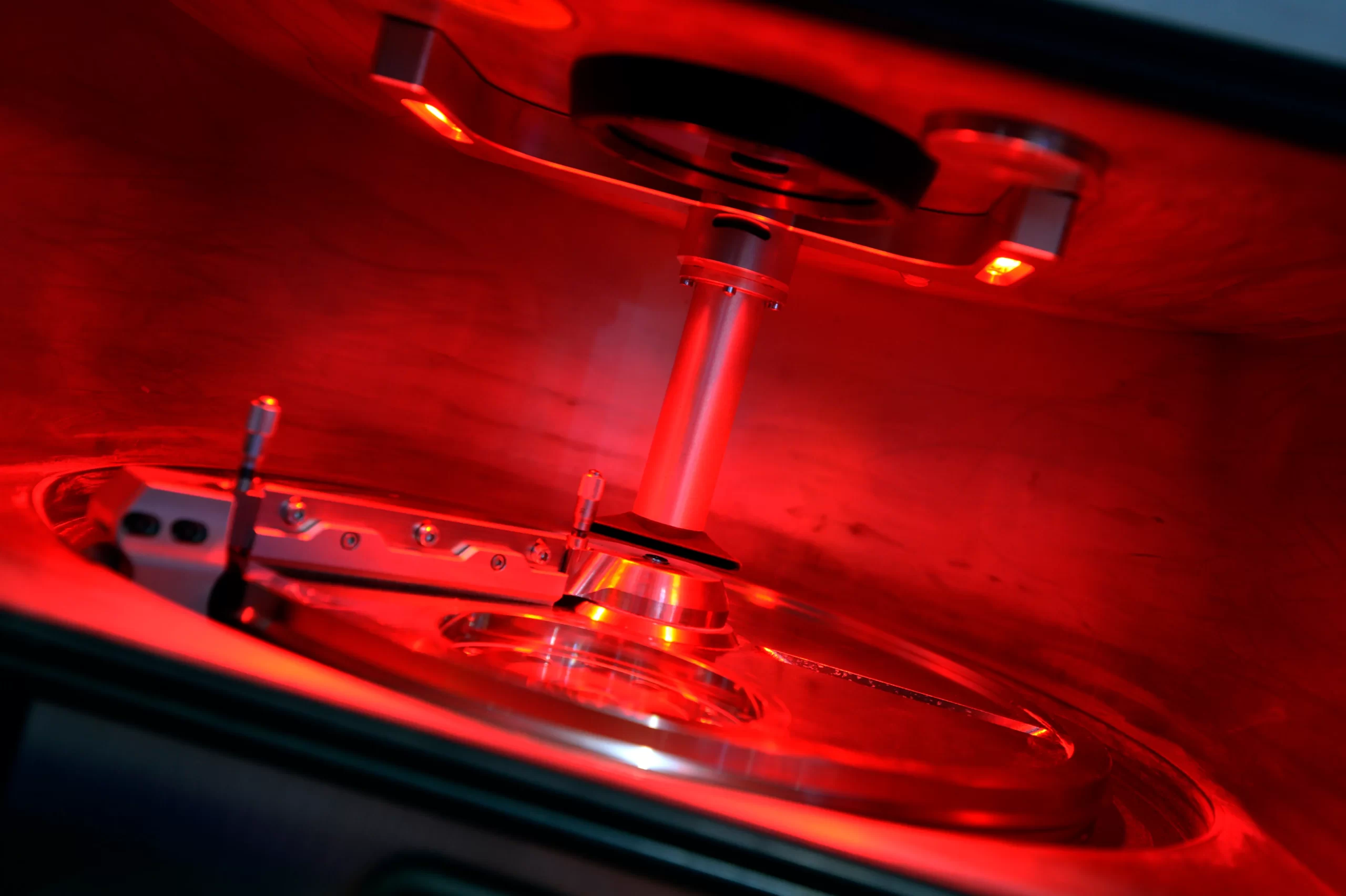

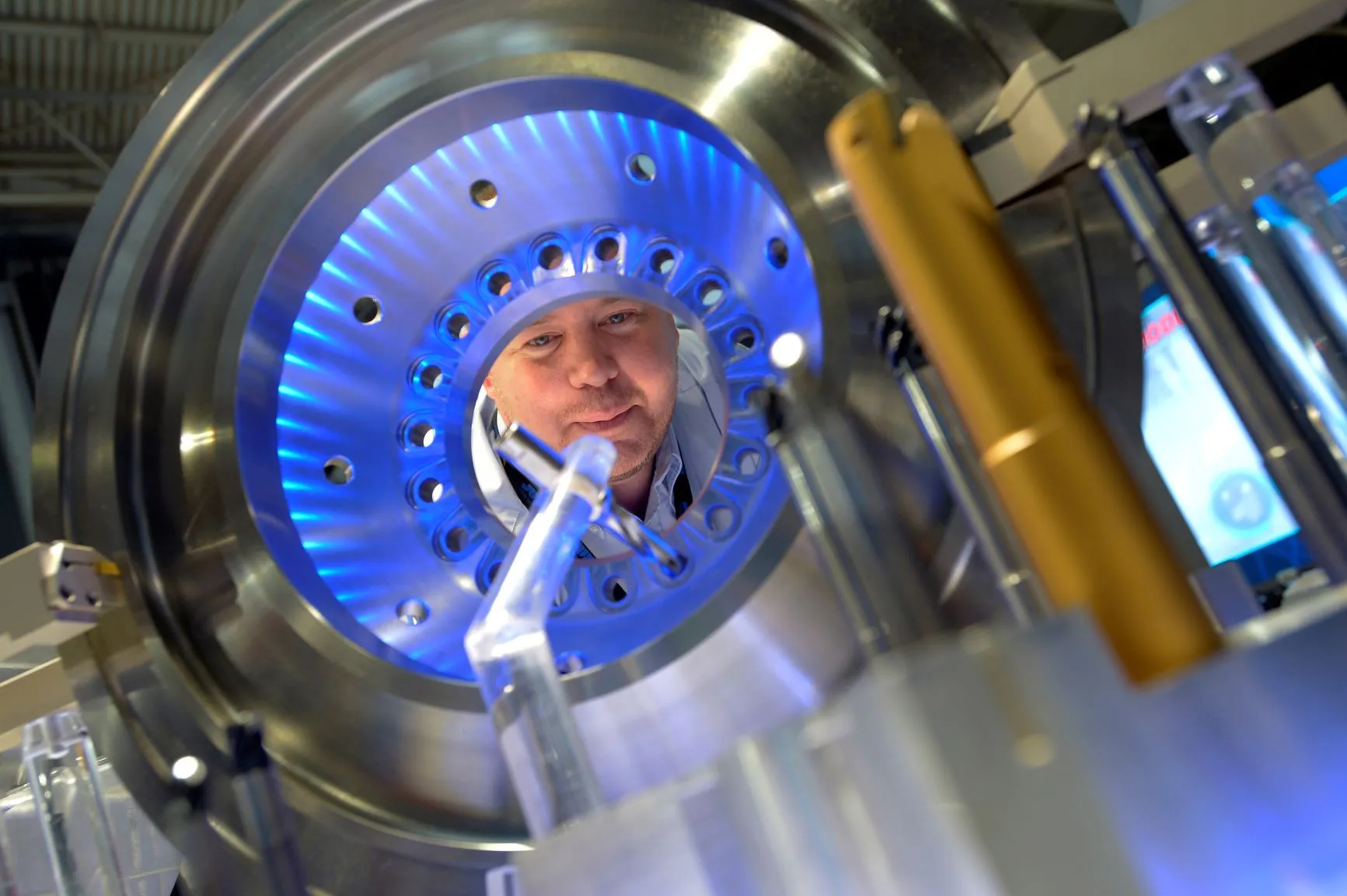

High purity cleaning combines solvent and plasma processes

Achieving residual organic contamination in the atomic percentage range In high-performance laser systems operating under high vacuum conditions, already minimal layers of organic residues can pose a risk of interfering with the process. This is why one of the leading laser manufacturers uses an EcoCcore machine with High Purity configuration and integrated, subsequent low-pressure plasma […]

Read more

How lights out manufacturing improves with Oemeta’s high-performance lubricants.

Lights-out Spotlight: Let the machines keep working after you go home. How lights out manufacturing improves with Oemeta’s high-performance lubricants. “Lights-out” or “dark factory” machining is the next step for greater productivity and profitability in UK manufacturing. With the growing reliability and cost-effectiveness of both robot loading and monitoring systems, coupled with a limited labour […]

Read more

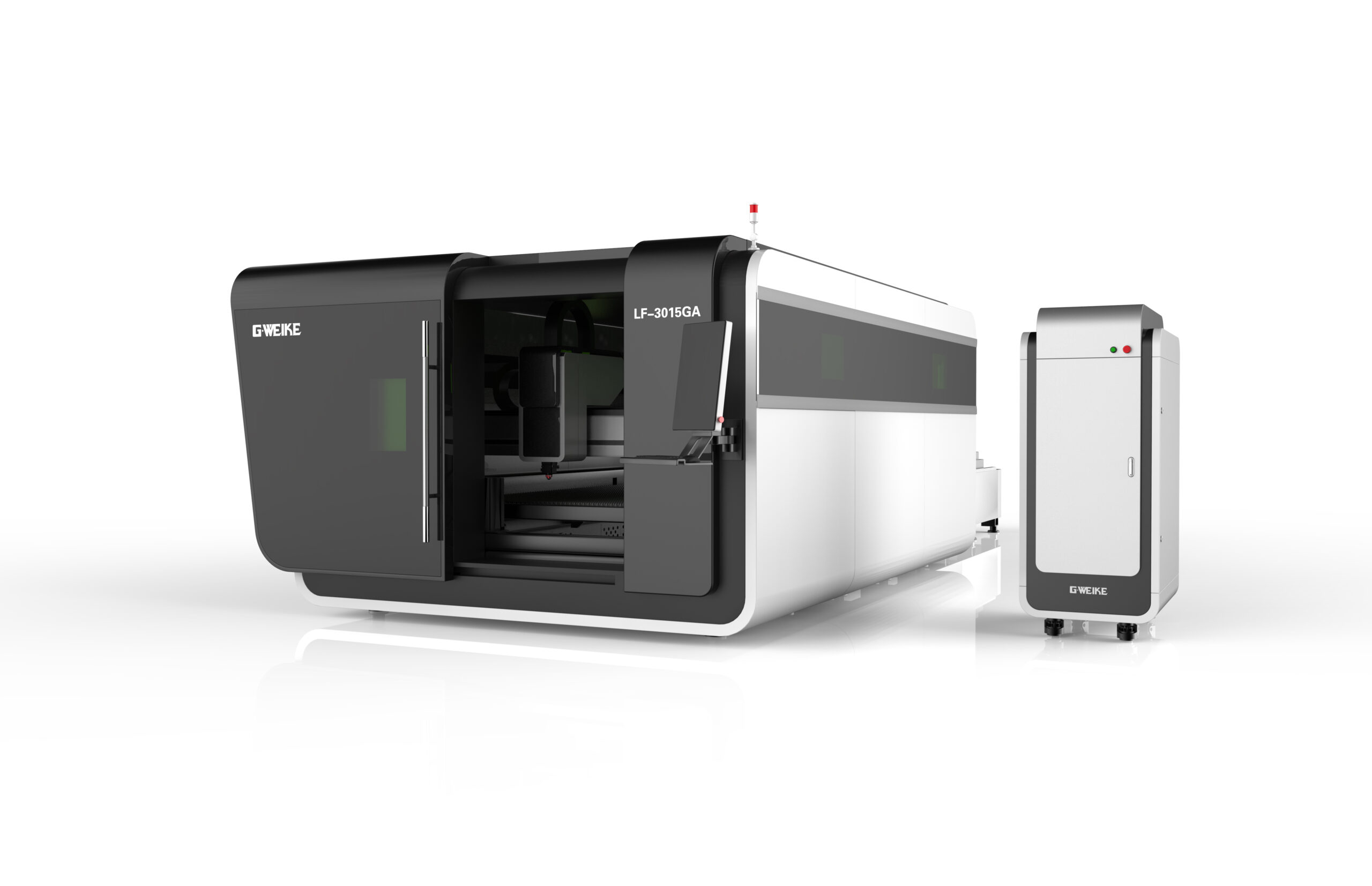

GWEIKE | WHOLE COVER FIBER LASER CUTTING MACHINE LF3015GA

Gweike presented the exhibition with “heavyweight” star equipment 6000W/LF 3015GA high-configuration fully enclosed laser cutter and new laser welding machine for welding, cutting, and cleaning all-in-one LCW series. 6000W/LF3015GA laser cutting machine The innovations and breakthroughs of the Gweike 6KW LF3015GA high-power laser cutting machine are mainly in technology. This 6KW laser machine has a […]

Read more

New Lubrication Specialist Joins ACORN

Andy Howard joins Acorn as the newly appointed lubrication product manager Acorn Industrial Services Ltd is delighted to announce the appointment of its new Lubrication Product Manager, Andy Howard. Andy brings with him 18 years of technical lubrication experience – specialising in lubricants for the food and beverage industry. Andy’s previous experience includes time as […]

Read more

Aberlink raises the bar with new CMM

/https://www.pesmedia.com/aberlink-raises-the-bar-with-new-cmm

Read more

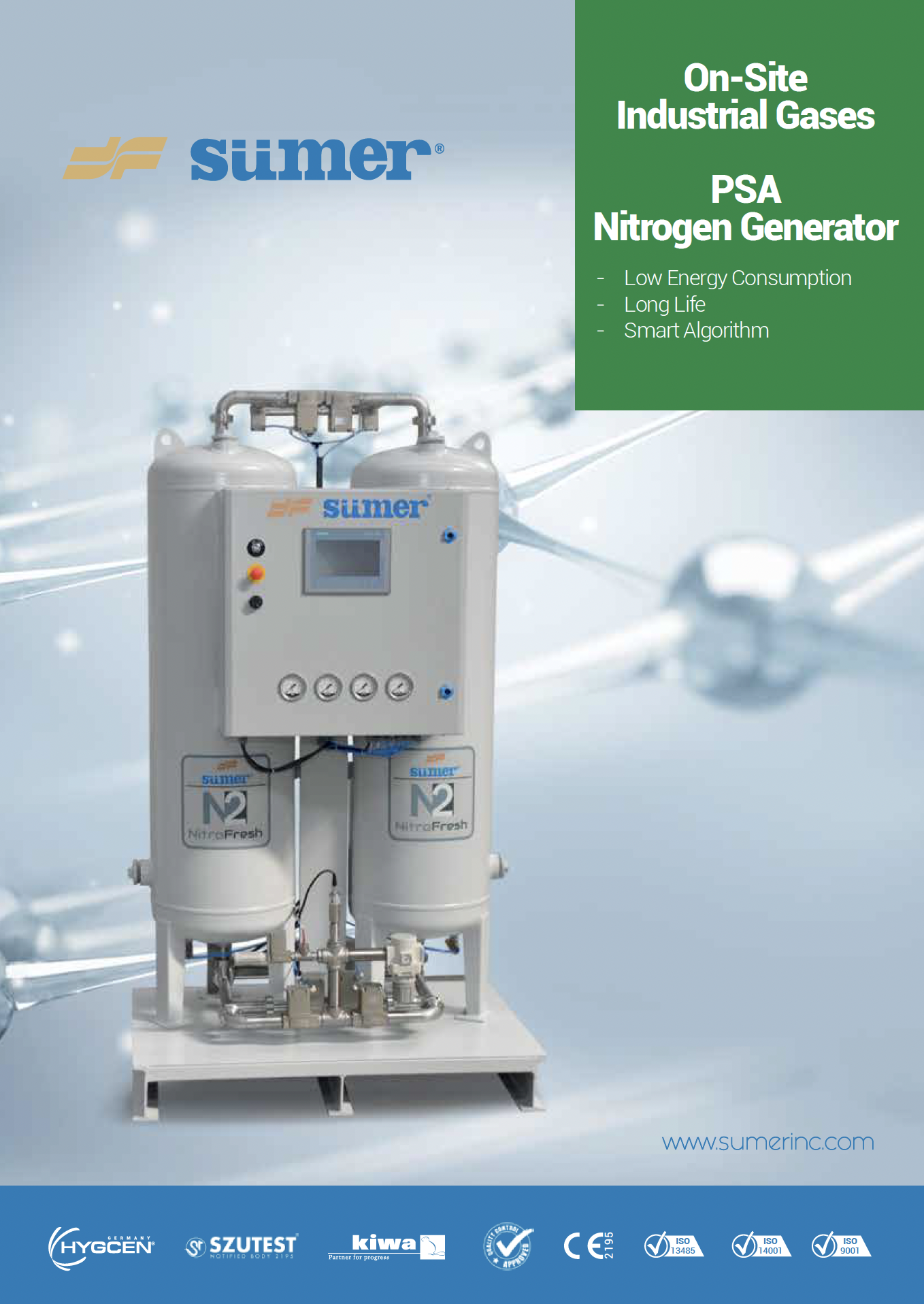

Sumer Nitrogen Generators

Pressure Swing Adsorption (PSA) technology is used with specially developed adsorbents called Carbon Molecular Sieve (CMS) to separate nitrogen from air to be able to use pure nitrogen in many applications. First, air is compressed up to 10 bars with the help of compressors, then air is dried out to remove the moisture in the […]

Read more