MACH 2026 Secures Prime Position as the UK’s Leading Manufacturing Event

/The ballots for MACH 2026 have concluded, and the floorplan is rapidly filling up.With strong onsite sales, MACH 2026 is already well over 50% occupied, and all stands are now available for booking. As the premier UK event for the manufacturing sector, MACH 2026 is the place to showcase cutting-edge technologies, connect with industry leaders, […]

Read more

MACH 2024 is hailed a roaring success

/MACH 2024, the UK’s national event for inspiring, innovating, and connecting manufacturing, has once again been hailed as a triumph, with thousands of visitors filling the five halls at the NEC in Birmingham over the weeklong show in April. The 2024 edition of the exhibition saw a 6% increase in the number of visitors meaning […]

Read more

Report reveals ‘True Impact’ of manufacturing is nearly a quarter of UK GDP

/Manufacturing is having a far greater impact on the UK economy than first thought according to a major new report released today. ‘The True Impact of UK Manufacturing’, which will be unveiled at MACH 2024 in Birmingham later, shows industry is worth £518billion and supports 7.3million UK jobs directly and across the supply chains/communities it […]

Read more

Visit the MMMA Metalworking Village in Hall 6 at MACH 2024

/Established in 1949, the Metalforming Machinery Makers Association (MMMA) is the only trade body solely dedicated to the sheet metalforming industry representing companies specialising in sheet metal, metalforming and fabrication. MMMA will be celebrating its 75th Anniversary at MACH 2024 which takes place between 15-19 April at the NEC Birmingham. MMMA is very excited to […]

Read more

Walking the floor: A starting point for sustainability

/New for MACH 2024, Lloyds Bank is hosting a Sustainability Solutions Hub at Stand 18-650 in partnership with the Manufacturing Technology Centre (MTC). For manufacturers looking to understand where to begin on their journey to Net Zero or what support is available, we are on hand to help. Here, David Atkinson, UK Head of Manufacturing […]

Read more

New Knowledge Hubs initiative at MACH 2024

/Reversing UK manufacturing’s poor record for adopting new technology will be tackled head on at MACH 2024 as The Manufacturing Technologies Association (MTA) launches its new Knowledge Hubs initiative, showcasing how to adopt new technology to improve productivity and efficiency in manufacturing.

Read more

Changing times: Manufacturers’ unprecedented opportunity

/We’re looking forward to meeting manufacturers from across the country at MACH 2024, to hear about their strategies for the year ahead and discuss how we can support.

Here David Atkinson, UK Head of Manufacturing SME & Mid Corporates, Lloyds Bank, and James Selka, CEO of Manufacturing Technologies Association (MTA) discuss their ambitions for the sector in 2024.

Sandvik Coromant announced as headline sponsor of the MACH 2024 Education & Development Zone

/The Education and Development (E&D) Zone at MACH 2024 is once again being sponsored by global metalcutting specialist, Sandvik Coromant.

Read more

Knowledge Hub initiative to be core theme of MACH 2024

/Reversing UK manufacturing’s poor record for adopting new technology will be tackled head on at MACH 2024. The Manufacturing Technologies Association (MTA) has made it its mission to spearhead growth by using its flagship event to launch its new Knowledge Hubs initiative. The programme showcases the latest technology to exhibitors, helping manufacturers learn more about […]

Read more

MTA announces flagship initiative to help UK manufacturers adopt latest technologies

/The Manufacturing Technologies Association (MTA) will use its flagship event, MACH 2024, to launch its new initiative to help UK manufacturers become more competitive while improving efficiency and sustainability. A series of Knowledge Hubs will feature at the exhibition, taking place at the NEC, Birmingham from 15-19 April 2024, all designed to encourage UK engineering-based […]

Read more

Avoiding Unplanned Downtime: Online Monitor of Critical Bearings

Avoiding Unplanned Downtime: Online Monitor of Critical Bearings Keeping a close eye on the condition of critical equipment is fundamental in any industrial facility. When critical bearings fail, it almost always leads to unplanned downtime and interrupted production process, costing companies thousands in production loses. In this case study we will look at how an […]

Read more

Ultrasound and Vibration analysis: two key elements of predictive maintenance

Vibration analysis has been for many years the technology of choice for maintenance professionals to monitor the condition of rotating assets. However, in the last years ultrasound has also emerged as a very popular technology for condition monitoring. The question that many are now asking themselves is: which one is best? Ultrasound or vibration? In […]

Read more

Electrical Equipment Reliability with Ultrasound & Infrared

Ultrasound and infrared technologies are a perfect match when conducting inspections of electrical equipment. At any voltage, thermal anomalies and sources of ultrasound such as tracking and arcing can occur. Corona can also occur at 1000 volts and greater. Any of these conditions threaten the reliability of the equipment being inspected. Typical electrical components that […]

Read more

Best Practices for Ultrasonic Compressed Air Leak Detection

Contrary to what some might think, compressed air is not free. In fact, for what it takes to produce it, to what is generated it is often considered the most expensive utility in a typical manufacturing facility. To further add to the problem, the US Department of Energy notes that more than 50% of all […]

Read more

Saving Energy by Inspecting Steam Traps with Ultrasound

High energy prices and global competition dictate a need to reduce energy waste and improve system efficiencies whenever possible. Steam, aside from being one of the costliest utilities in plants, is an essential component to product quality in many processing industries. A major contributor to waste and inefficiency is leaks: both to atmosphere and through […]

Read more

Case Study: Slow-Speed Bearing on Oven Motor – Failure Detection using Ultrasound

Slow Speed Bearing Inspection with Ultrasound Vibration analysis has long been the instrument of choice to use for bearings and other rotating equipment. More commonly, ultrasound is being used in conjunction with vibration analysis to help technicians confirm the condition of mechanical assets. Because of the versatility of ultrasound, if a facility does not have […]

Read more

Certification Training – the foundation of a successful Ultrasound program

Ultrasound has already become one of the most important, reliable, and widely used technologies by maintenance professionals all over the world. Its many applications (from leak detection to a complete bearing monitoring and lubrication program) and the quick learning curve makes it highly popular among inspectors. But to get the maximum out of an ultrasonic […]

Read more

Listen to your bearings: Improve lubrication practices with Ultrasound

Keeping a handle on lubrication is easy, right? All one needs to do is make sure the right lubricant is used in the right amount and at the right time. Not so fast; if only it were that simple. It has been estimated that 60-90% of all bearing failures are lubrication related. Bearing failures most […]

Read more

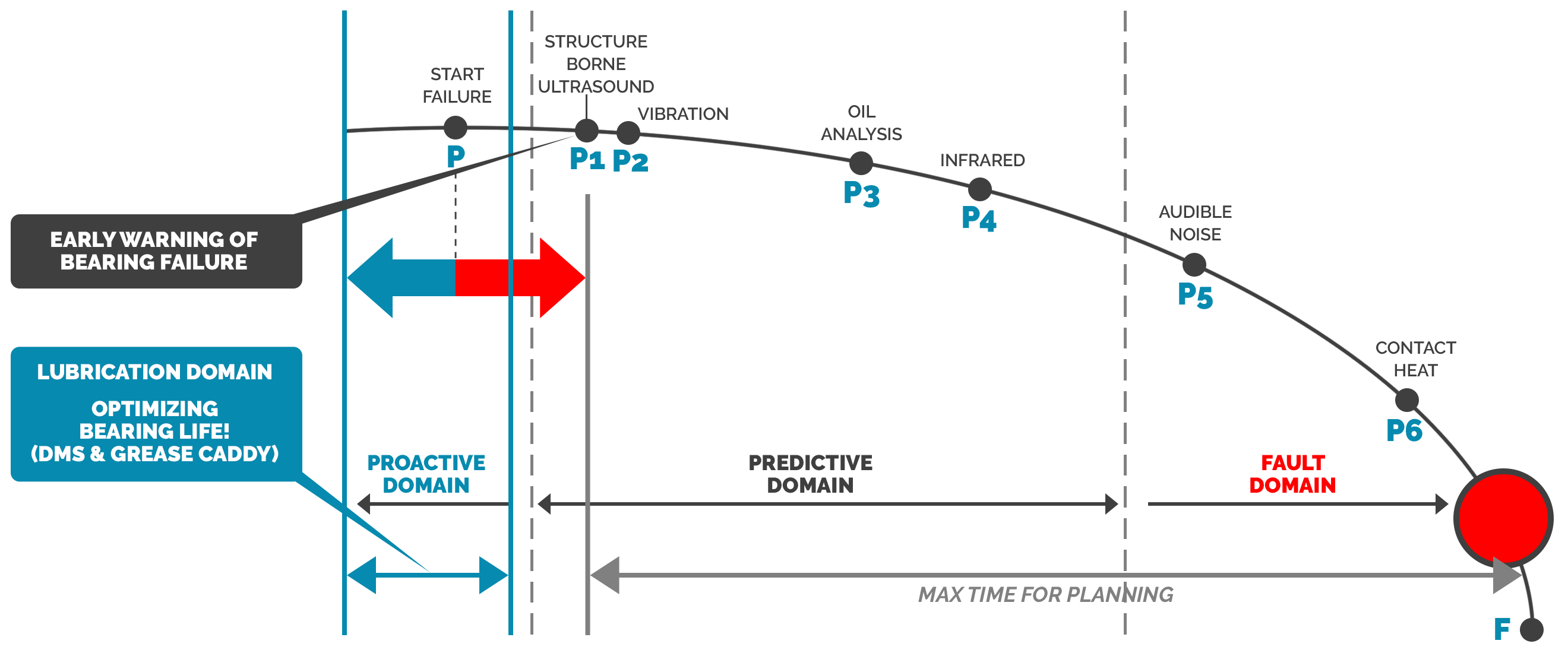

Bearing Condition Monitoring Using Ultrasound

Airborne & structure-borne ultrasound has become a major player in bearing condition monitoring. Once considered just a leak detector, more maintenance & reliability professionals are beginning to realize all of the benefits associated with using ultrasound for condition monitoring applications. The P-F Curve with which we have all become familiar with reflects that trend. It […]

Read more

Ultrasound Cameras: the quickest way to energy savings

When companies wish to reduce the energy cost of their industrial facilities, finding and repairing existing compressed air leaks is an excellent starting point. But such a task requires time, personnel, and the right tools. Thus, efficiency is key when it comes to carrying on a leak detection program. And, right now, nothing is more […]

Read more