Visit the MMMA Metalworking Village in Hall 6 at MACH 2024

/Established in 1949, the Metalforming Machinery Makers Association (MMMA) is the only trade body solely dedicated to the sheet metalforming industry representing companies specialising in sheet metal, metalforming and fabrication. MMMA will be celebrating its 75th Anniversary at MACH 2024 which takes place between 15-19 April at the NEC Birmingham. MMMA is very excited to […]

Read more

Walking the floor: A starting point for sustainability

/New for MACH 2024, Lloyds Bank is hosting a Sustainability Solutions Hub at Stand 18-650 in partnership with the Manufacturing Technology Centre (MTC). For manufacturers looking to understand where to begin on their journey to Net Zero or what support is available, we are on hand to help. Here, David Atkinson, UK Head of Manufacturing […]

Read more

New Knowledge Hubs initiative at MACH 2024

/Reversing UK manufacturing’s poor record for adopting new technology will be tackled head on at MACH 2024 as The Manufacturing Technologies Association (MTA) launches its new Knowledge Hubs initiative, showcasing how to adopt new technology to improve productivity and efficiency in manufacturing.

Read more

Changing times: Manufacturers’ unprecedented opportunity

/We’re looking forward to meeting manufacturers from across the country at MACH 2024, to hear about their strategies for the year ahead and discuss how we can support.

Here David Atkinson, UK Head of Manufacturing SME & Mid Corporates, Lloyds Bank, and James Selka, CEO of Manufacturing Technologies Association (MTA) discuss their ambitions for the sector in 2024.

Sandvik Coromant announced as headline sponsor of the MACH 2024 Education & Development Zone

/The Education and Development (E&D) Zone at MACH 2024 is once again being sponsored by global metalcutting specialist, Sandvik Coromant.

Read more

Knowledge Hub initiative to be core theme of MACH 2024

/Reversing UK manufacturing’s poor record for adopting new technology will be tackled head on at MACH 2024. The Manufacturing Technologies Association (MTA) has made it its mission to spearhead growth by using its flagship event to launch its new Knowledge Hubs initiative. The programme showcases the latest technology to exhibitors, helping manufacturers learn more about […]

Read more

MTA announces flagship initiative to help UK manufacturers adopt latest technologies

/The Manufacturing Technologies Association (MTA) will use its flagship event, MACH 2024, to launch its new initiative to help UK manufacturers become more competitive while improving efficiency and sustainability. A series of Knowledge Hubs will feature at the exhibition, taking place at the NEC, Birmingham from 15-19 April 2024, all designed to encourage UK engineering-based […]

Read more

Manufacturers pledge support for MACH 2024 with more than 80% of exhibition space sold

/The UK’s engineering-based manufacturing sector has once again backed the industry’s largest trade show, booking more than 80% of floorspace at MACH 2024 with more than 200 days still to go before doors open at the NEC in Birmingham. Show organiser, the Manufacturing Technologies Association (MTA) said it was delighted with the response but stressed […]

Read more

Lloyds Bank confirmed as headline sponsor of MACH 2024

/The countdown to MACH 2024, the UK’s national event for inspiring, innovating and connecting manufacturing, has reached an important landmark, with just one year to go before the doors to the National Exhibition Centre in Birmingham open for the UK’s national event for engineering-based manufacturing. In recognition of the landmark – and reaffirming their commitment […]

Read more

Sustainability to be the watchword for MACH 2024

/MACH 2024, already expected to be one of the most important exhibitions in the event’s illustrious history, is also set to the most sustainable. With challenges mounting for the UK’s engineering-based manufacturers, MACH 2024 organiser, the Manufacturing Technologies Association is taking a proactive approach to the current situation with a show-ready ethos that promotes the […]

Read more

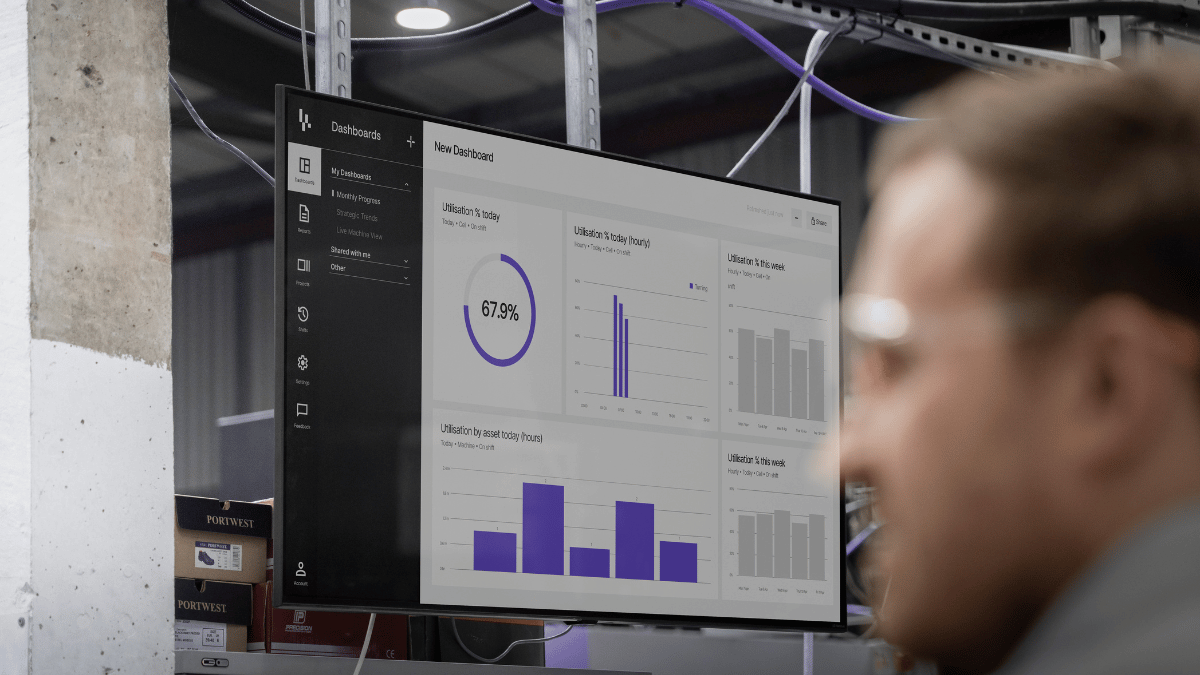

Report highlights “fundamental production data” as the key to factory visibility and productivity

/A new report from FourJaw Manufacturing Analytics suggests most manufacturers are “stuck between a rock and a hard place” when it comes to understanding their production environments. Research indicates that less than 1% of factory data is analysed effectively, and that 70% of manufacturers still rely on error-prone manual data collection methods. These data issues […]

Read more

Redefining process reliability in milling

MAPAL’s third generation of the versatile OptiMill-Uni-HPC for steel, stainless steel and cast-iron machining has been specifically developed for the requirements of modern, automated manufacturing processes. The solid carbide milling cutters impress with maximum process reliability – a key factor in the era of unmanned shifts, robot-assisted machining and growing complexity in component manufacturing. The […]

Read more

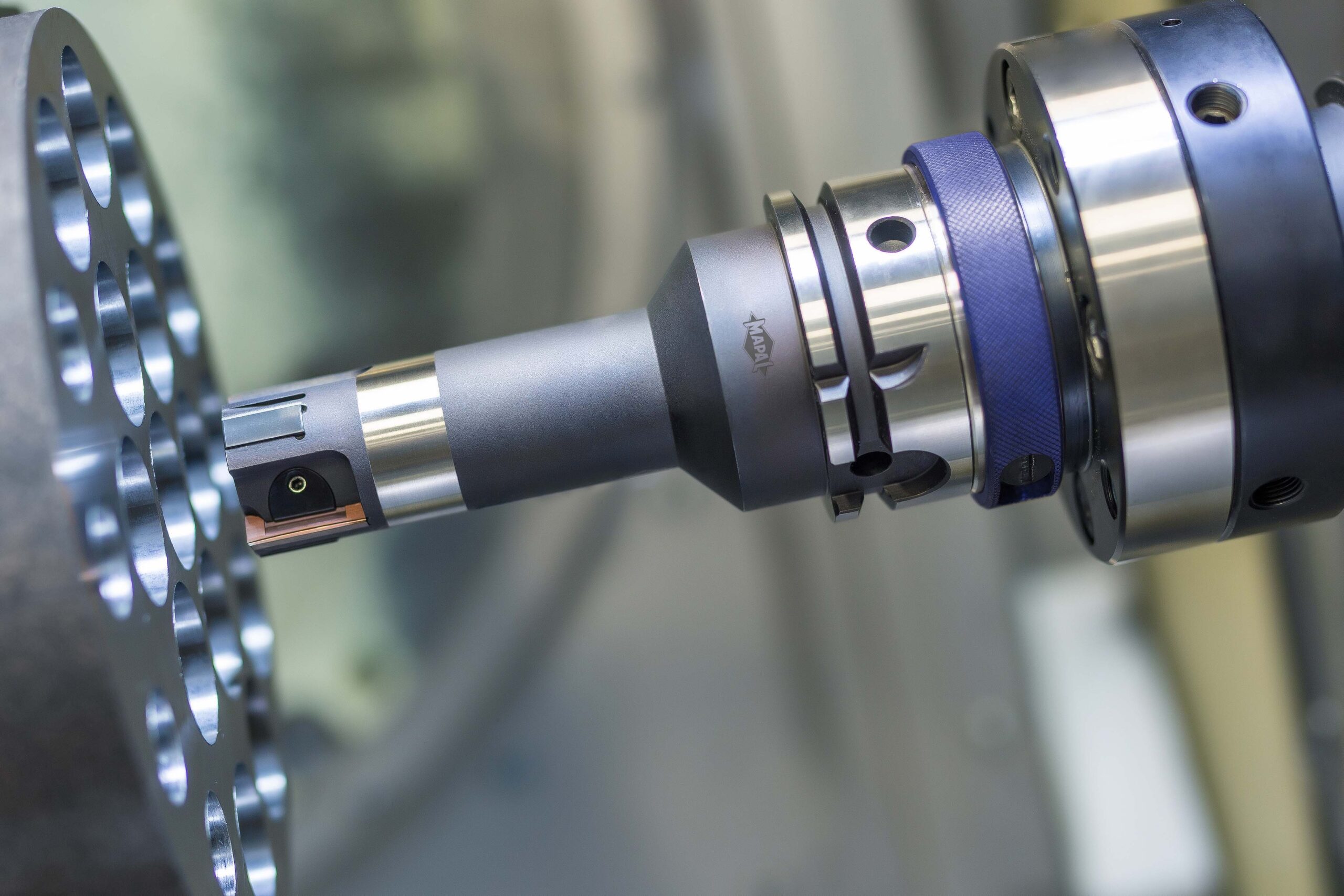

Paths to Greater Productivity with Solutions from MAPAL

MAPAL presents successful solutions on the market Maximum impact with minimal effort – paths to greater productivity production of strategic components. On that basis, these tool solutions are modified according to requirements, to help customers boost their productivity. Success stories from various market segments show just how well this works. Productivity is boosted when the […]

Read more

One-of-a-kind service from MAPAL Indonesia

Minimum quantity lubrication makes “green” production possible MAPAL in Indonesia has paved new trails to modernise a major client’s production. The Aalen-based tool manufacturer’s subsidiary not only supplies an automotive supplier with tools for use with minimum quantity lubrication (MQL), but has also taken over distribution and service for the facilities. Astra Otoparts is one […]

Read more

Standardised chip breaker geometry for long-chipping steel materials

Innovative machining solutions for P and M steels set new standards Machining long-chipping steel materials like stainless steels has always been a challenge. With the development of a new, standardised chip breaker geometry for fine boring blades, MAPAL has achieved a crucial breakthrough that has both technical and economic benefits. In metal machining, chip formation […]

Read moreHistorical Dashboards Coming to CIMCO MDC-Max Web Client

On the shop floor, managers and operators need clear insight not only into what is happening right now, but also into what has happened over time. While the existing Dashboards in the MDC-Max Web Client focus on live, real-time data, users often also need to dig into the history – to uncover trends, compare performance, […]

Read moreJump to Cut in CIMCO Edit 2025 and NC Machine Simulation

The new Jump to Cut feature in CIMCO Edit 2025 makes it faster and easier than ever to analyze toolpath simulations. Instead of manually scrubbing through the simulation timeline, you can now simply right-click on the simulated stock and select “Jump to Cut.” The simulation will instantly jump to the exact toolpath or NC line […]

Read more

Putting heads together for the last diesel engine

Fine boring tools from MAPAL for MAN diesel tools At commercial vehicle manufacturer MAN Truck & Bus’s Nuremberg plant, production of an ultra-efficient new 13-litre diesel engine has begun. As a joint engine platform, it is intended for use across the group. Fine boring tools from MAPAL are used for the cylinder heads. These machine […]

Read more

75 years of MAPAL

In a history now spanning 75 years, the family business MAPAL has gone from humble beginnings to an international group with a global reputation. From the very beginning, the tool manufacturer’s company history has been characterised by continuity and an innovative spirit that was nourished by Swabian ingenuity and creativity, as well as by the […]

Read more

Redefining process reliability in milling

MAPAL’s third generation of the versatile OptiMill-Uni-HPC for steel, stainless steel and cast-iron machining has been specifically developed for the requirements of modern, automated manufacturing processes. The solid carbide milling cutters impress with maximum process reliability – a key factor in the era of unmanned shifts, robot-assisted machining and growing complexity in component manufacturing. The […]

Read more