Lloyds Bank confirmed as headline sponsor of MACH 2024

/The countdown to MACH 2024, the UK’s national event for inspiring, innovating and connecting manufacturing, has reached an important landmark, with just one year to go before the doors to the National Exhibition Centre in Birmingham open for the UK’s national event for engineering-based manufacturing. In recognition of the landmark – and reaffirming their commitment […]

Read more

Sustainability to be the watchword for MACH 2024

/MACH 2024, already expected to be one of the most important exhibitions in the event’s illustrious history, is also set to the most sustainable. With challenges mounting for the UK’s engineering-based manufacturers, MACH 2024 organiser, the Manufacturing Technologies Association is taking a proactive approach to the current situation with a show-ready ethos that promotes the […]

Read more

UK’s engineering and manufacturing communities urged to secure space at MACH 2024 now

/The Manufacturing Technologies Association, the owner and organiser of the MACH 2024 exhibition, is advising potential exhibitors to sign up for the event now, following unprecedented demand for exhibition space at the show. Despite the doors of MACH 2024 not opening for another eighteen months, the exhibition has already received strong support from MTA members […]

Read more

MACH 2022 proves major catalyst for manufacturing investment

/MACH 2022, the largest display of new machinery and manufacturing technologies under one roof in the UK for four years, lived up to its billing as a major catalyst for investment with scores of exhibitors reporting strong sales and positive interest in their products during the five-day event at Birmingham’s National Exhibition Centre. And in […]

Read more

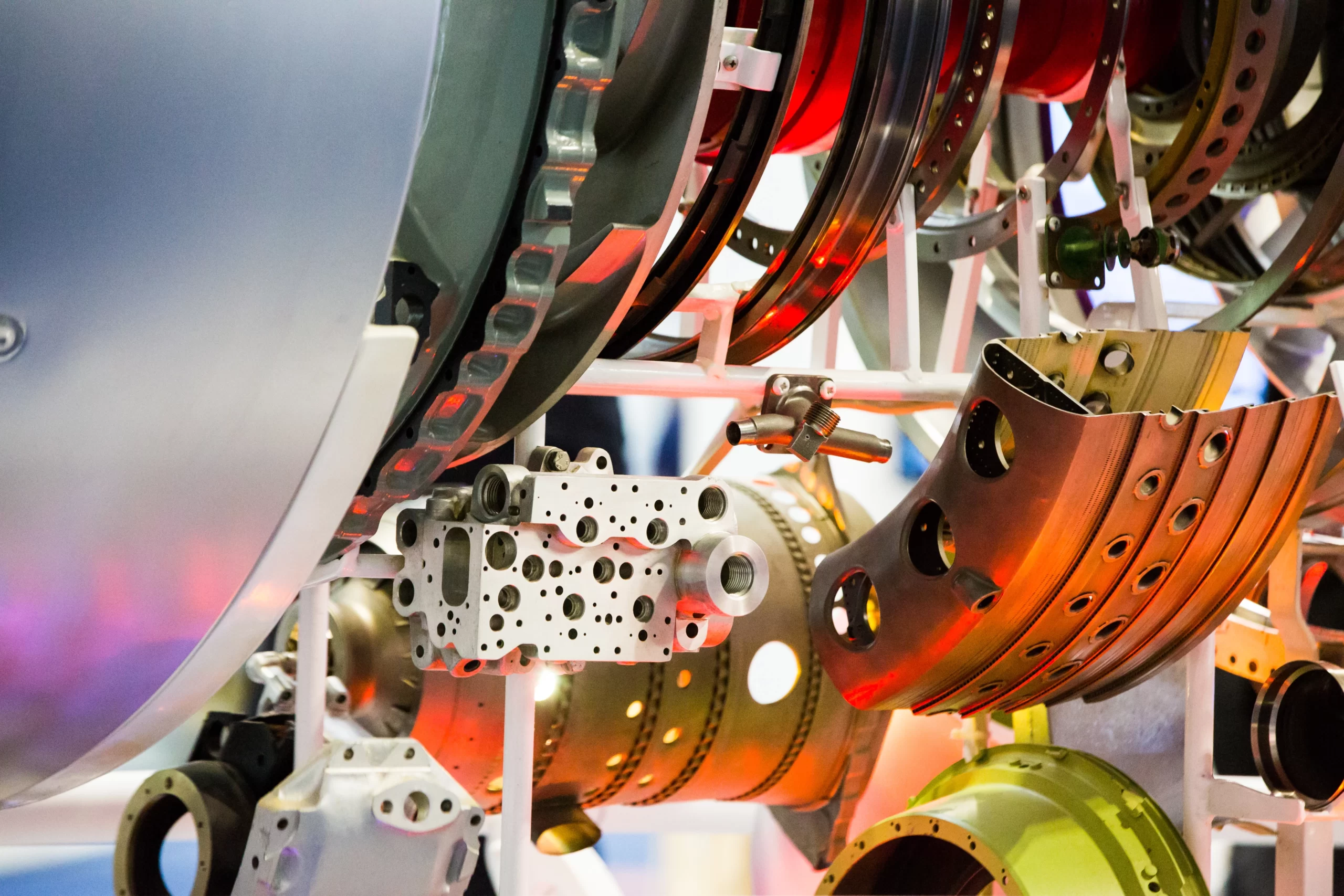

MMMA Metalworking Village proudly showcases core strengths of UK’s metalworking industry

/The core strengths of the UK’s metalworking industry are proudly on display in what is, one of the largest themed zones at MACH 2022. The Metalforming Machinery Makers’ Association’s (MMMA) Metalworking Village, which occupies 650m² of floorspace, showcases the skills and expertise of more than 20 association members. On display across the zone is an […]

Read more

AI Innovation Zone showcases the emerging technologies helping make manufacturers more productive and sustainable

/Innovative companies developing the emerging technologies that will help to shape the future of the UK’s manufacturing industry are getting their own showcase at MACH 2022. The AI Innovation Zone, supported by Made Smarter Innovation, showcases the work of 12 start up and scale ups utilising the power of data analytics, Artificial Intelligence (AI), and […]

Read more

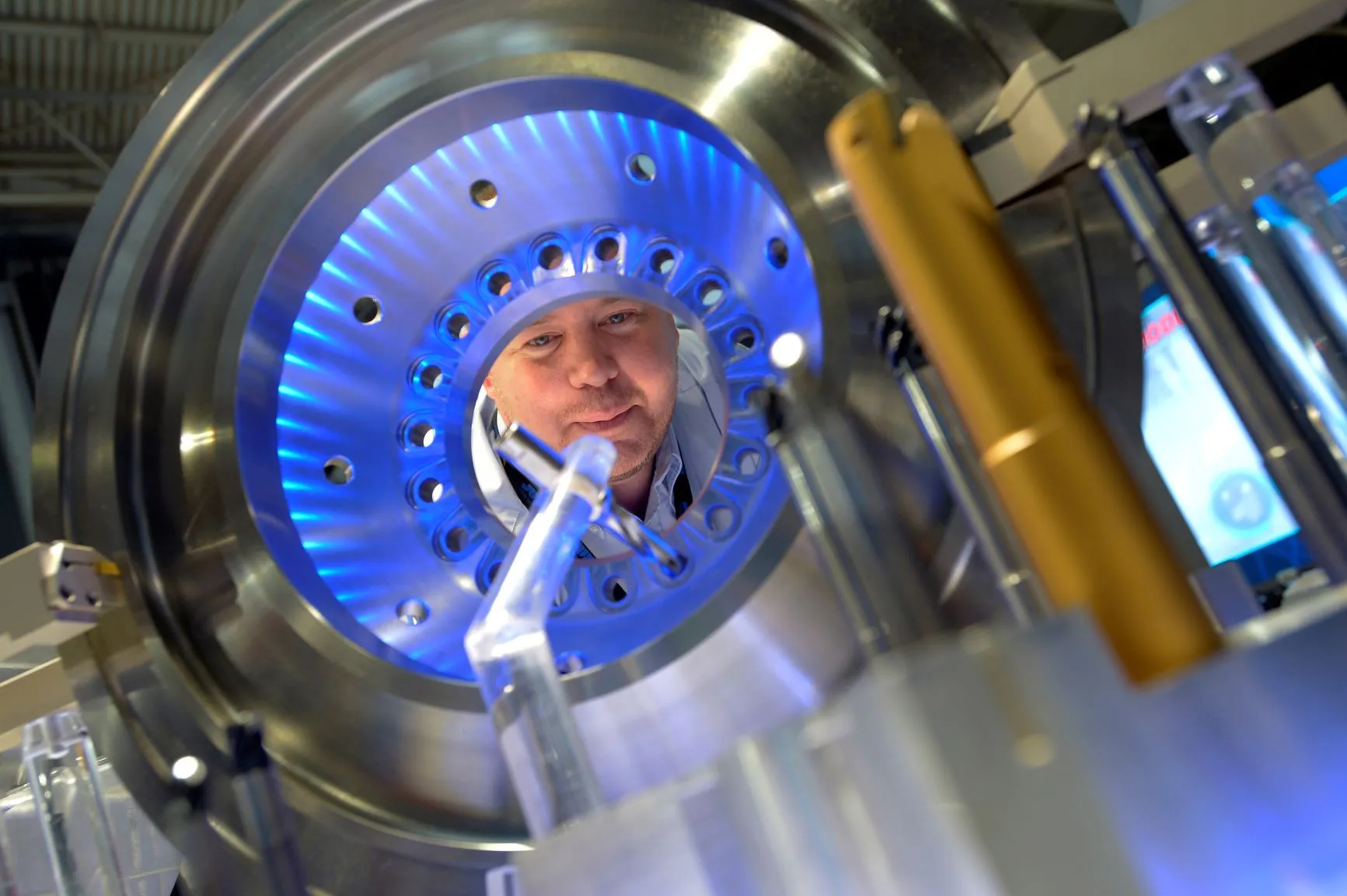

What to expect at MACH 2022

/MACH is the longest-running manufacturing and engineering exhibition in the UK and its distinctive ability to showcase the largest variety of manufacturing technology solutions in the country makes it unique in the industry and therefore, of critical importance to the sector. This year’s show will focus on the best of the manufacturing technologies sector – […]

Read more

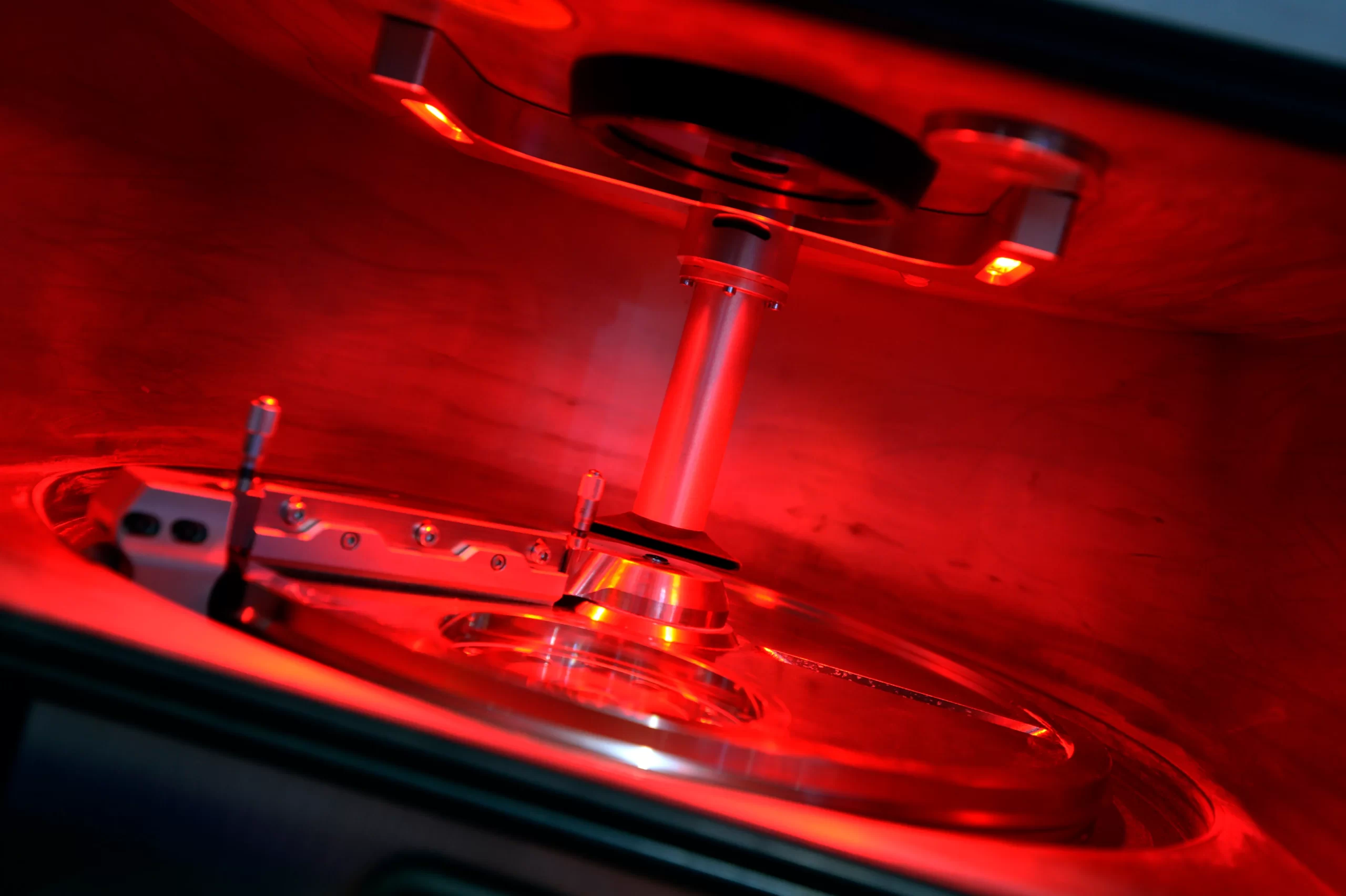

Additive Manufacturing to be key theme of MACH 2022

/The ability of Additive Manufacturing (AM) to be a significant disruptive technology for UK manufacturers will receive a special event at MACH 2022. Spearheading the initiative will be the only trade association dedicated to the Additive Manufacturing sector, AM-UK. AM-UK is specifically designed for companies who work with Additive and 3D printing technology – such […]

Read more

MACH 2022 is the must-attend event for the UK’s engineering and manufacturing communities

/MACH 2022, which opens its doors at the NEC in Birmingham on Monday, is set to be the most significant gathering of manufacturers in the UK post-pandemic. Against a backdrop of growing cost pressures on manufacturers, the arrival of the event could not be timelier offering as it does, the largest display of new machinery […]

Read more

Don’t Miss Your Opportunity to Have Your Tooling Challenges Resolved by Experts at the MACH 2022 Tooling Clinic

/Visitors to MACH 2022 are being offered the unique opportunity to have their tooling challenges resolved free-of-charge by a team of expert – and independent – tooling specialists.

Read more

Ultrasound and Vibration analysis: two key elements of predictive maintenance

Vibration analysis has been for many years the technology of choice for maintenance professionals to monitor the condition of rotating assets. However, in the last years ultrasound has also emerged as a very popular technology for condition monitoring. The question that many are now asking themselves is: which one is best? Ultrasound or vibration? In […]

Read more

Electrical Equipment Reliability with Ultrasound & Infrared

Ultrasound and infrared technologies are a perfect match when conducting inspections of electrical equipment. At any voltage, thermal anomalies and sources of ultrasound such as tracking and arcing can occur. Corona can also occur at 1000 volts and greater. Any of these conditions threaten the reliability of the equipment being inspected. Typical electrical components that […]

Read more

Best Practices for Ultrasonic Compressed Air Leak Detection

Contrary to what some might think, compressed air is not free. In fact, for what it takes to produce it, to what is generated it is often considered the most expensive utility in a typical manufacturing facility. To further add to the problem, the US Department of Energy notes that more than 50% of all […]

Read more

Saving Energy by Inspecting Steam Traps with Ultrasound

High energy prices and global competition dictate a need to reduce energy waste and improve system efficiencies whenever possible. Steam, aside from being one of the costliest utilities in plants, is an essential component to product quality in many processing industries. A major contributor to waste and inefficiency is leaks: both to atmosphere and through […]

Read more

Case Study: Slow-Speed Bearing on Oven Motor – Failure Detection using Ultrasound

Slow Speed Bearing Inspection with Ultrasound Vibration analysis has long been the instrument of choice to use for bearings and other rotating equipment. More commonly, ultrasound is being used in conjunction with vibration analysis to help technicians confirm the condition of mechanical assets. Because of the versatility of ultrasound, if a facility does not have […]

Read more

Certification Training – the foundation of a successful Ultrasound program

Ultrasound has already become one of the most important, reliable, and widely used technologies by maintenance professionals all over the world. Its many applications (from leak detection to a complete bearing monitoring and lubrication program) and the quick learning curve makes it highly popular among inspectors. But to get the maximum out of an ultrasonic […]

Read more

Listen to your bearings: Improve lubrication practices with Ultrasound

Keeping a handle on lubrication is easy, right? All one needs to do is make sure the right lubricant is used in the right amount and at the right time. Not so fast; if only it were that simple. It has been estimated that 60-90% of all bearing failures are lubrication related. Bearing failures most […]

Read more

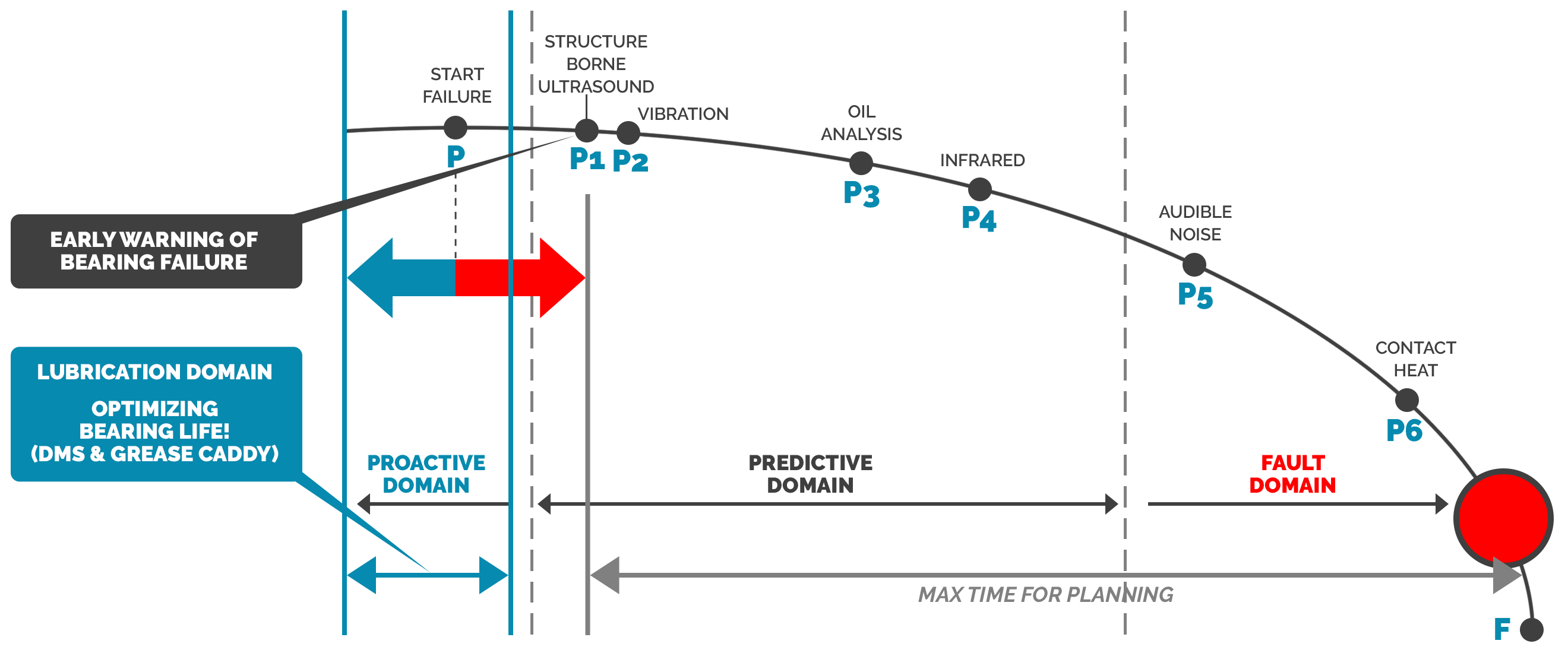

Bearing Condition Monitoring Using Ultrasound

Airborne & structure-borne ultrasound has become a major player in bearing condition monitoring. Once considered just a leak detector, more maintenance & reliability professionals are beginning to realize all of the benefits associated with using ultrasound for condition monitoring applications. The P-F Curve with which we have all become familiar with reflects that trend. It […]

Read more

Ultrasound Cameras: the quickest way to energy savings

When companies wish to reduce the energy cost of their industrial facilities, finding and repairing existing compressed air leaks is an excellent starting point. But such a task requires time, personnel, and the right tools. Thus, efficiency is key when it comes to carrying on a leak detection program. And, right now, nothing is more […]

Read more

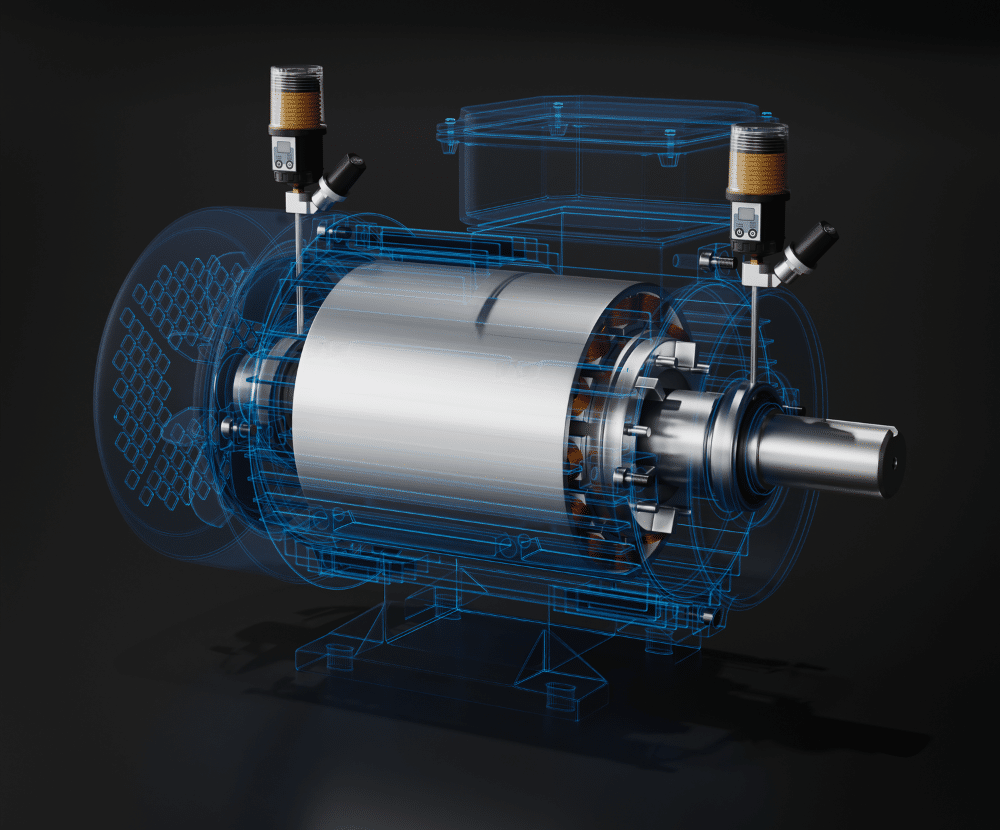

UE Systems revolutionizes Bearing Maintenance with the launch of OnTrak Wireless

UE Systems, a pioneering force in developing ultrasonic detection instruments and solutions for maintenance and reliability, unveils its latest innovation – the OnTrak Wireless system. This cutting-edge solution transcends traditional bearing health monitoring by actively preventing failures through precision autonomous lubrication, addressing lubrication-related issues which account for a significant portion of premature bearing failures. This […]

Read more