On Stand 432 in Hall 20 at MACH 2024, Industrial Tooling Corporation (ITC) will showcase its unsurpassed range of new cutting tool solutions. The Tamworth cutting tool manufacturer will present its latest product lines as well as cutting tool solutions from BIG KAISER, Karnasch, Kemmler, Bass and WIDIA.

As the UK partner for the world leading WIDIA brand of cutting tools, ITC will introduce all the latest solid carbide and indexable solutions – many of which will be making a MACH exhibition debut. The VariMill range of end mills has been the standout performer in the industry for several years with WIDIA continually evolving the industry’s most dynamic range of end mills for high-performance machining. Now, the VariMill series has been improved once again with the arrival of the VariMill Chip Splitter range.

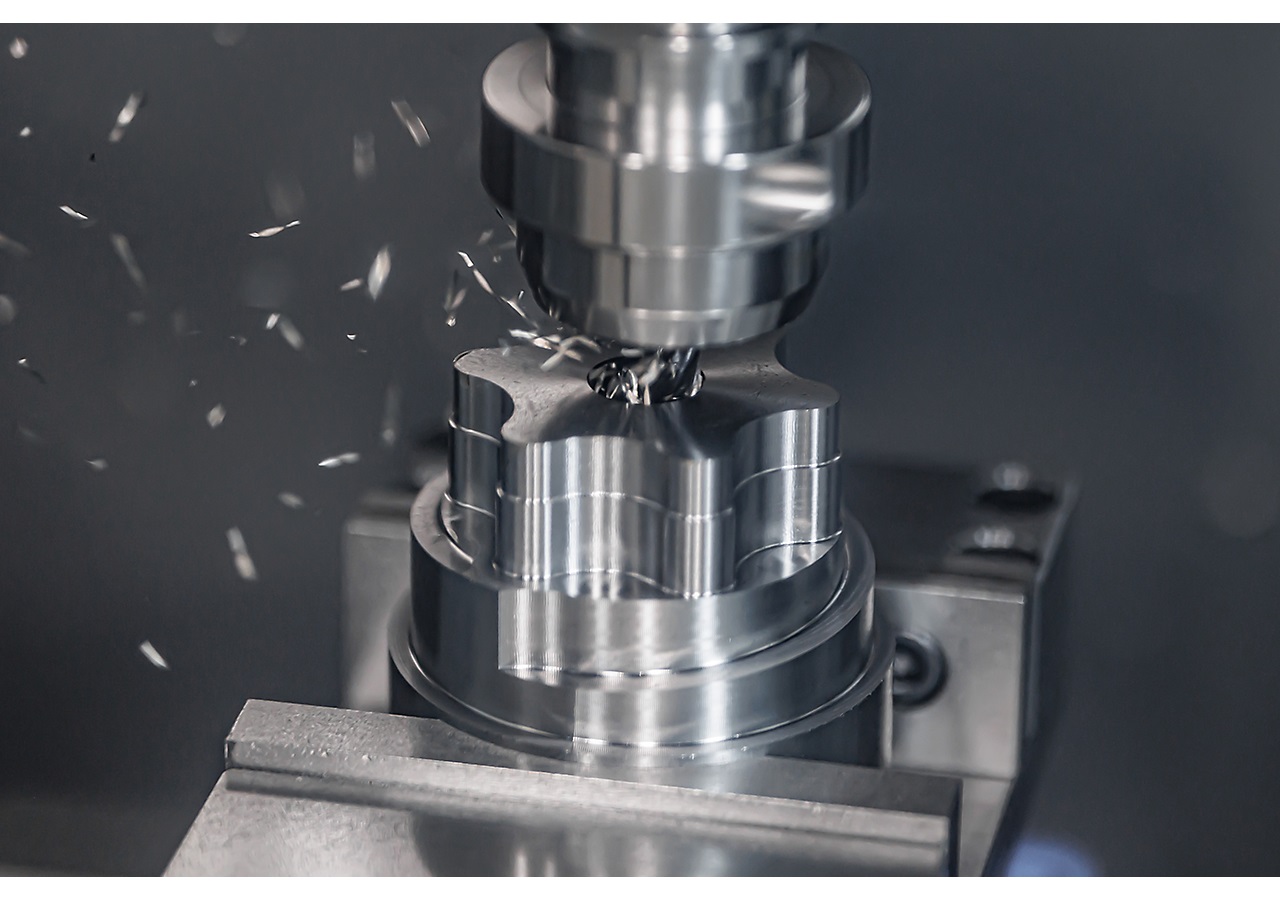

Designed for dynamic milling, ramping, helical interpolating and side milling at high speeds and feed rates, the new VariMill Chip Splitter series delivers exceptional chip control that allows the tool to run with a longer axial depth of cut while productively diving into deep pockets in steel, stainless steel and high-temperature alloys. Suitable for cutting materials ISO groups P, M, K, S and H, the new series is a genuine high-performance tool.

Presented as a 5-flute solid carbide end mill that is available in WIDIA’s WP15PE and WS15PE carbide grades, the new VariMill Chip Splitter has features incorporated that improve chip evacuation by breaking the chips into the smallest possible segments. The 5-flute end mills are available with a straight or Weldon shank in 3XD or 5XD variants. The straight shank 3XD end mills are available in 10, 12 and 16mm diameters with the Weldon shank designation also offering a 20mm diameter variant. Similarly, the 5XD plain shank variant is available from 10 to 20mm diameter with the Weldon shank also offering an 8mm diameter variant. Complementing the 5-flute variant will be the new 7-flute end mills that are also available with a straight or Weldon shank in 3XD or 5XD variants.

Alongside the 5 and 7 flute end mills will be the Hanita VariMill XTREME. The solid end milling brand delivers high-performance that is a significant advancement upon its predecessors from the iconic VariMill Series. The VariMill XTREME has been engineered to excel in a variety of aggressive machining conditions, enhancing chip evacuation and corner stability to exceed performance expectations on a wide range of materials. The impressive 4-flute solid carbide end mill is offered with a choice of geometries that include a square-end, sharp edges, chamfers and corner radii designs and it is available in diameters from 3 to 25mm.

For machining aluminium, the WIDIA Hanita Aluflash Series will be showcased at MACH 2024. Perfect for slotting, ramping, side milling, plunging, interpolating, dynamic and helical milling, the series of 2 and 3 flute solid carbide end mills are available in diameters from 1 to 25mm with a square-end or corner radius, stub, standard, long and extra-long lengths.

From the indexable milling range, ITC will once again show the WIDIA™ M1600 face mill series for roughing to semi-finishing operations in steel, stainless steel, cast iron and nodular iron materials. With a smart insert design, the M1600 performs exceptionally well under various machining conditions including low-power machines, unstable, non-rigid setups, long overhangs and weak fixture conditions. The 16-edged, precision-ground insert with a positive geometry enables low cutting forces and low power consumption resulting in higher tool life and an excellent cost per edge. The WP35CM grade targets all types of steel, while the WK15CM grade is designed for cast iron materials and is available in six metric diameter ranges between 50mm and 160mm.

Complementing the M1600 at MACH will be the M8065HD milling system for machining steel and cast-iron materials. Designed with eight cutting edges and extra-wide chip gashes, the new M8065HD is capable of achieving deep depths of cuts while producing high metal removal rates during face and shoulder milling applications. Completing the indexable face milling series will be the expanded VSM890-12. Hailed as one of the very few 8-edged double-sided milling lines with genuine 90-degree milling, the VSM890-12 has been increased with the arrival of its new MM insert geometry. The high-performance milling can conduct face, shoulder, Z-axis and contour plunging and 100% radial engagement slotting.

For highly productive holemaking, the expanded WIDIA TOP DRILL™ TDMX modular drilling line will be shown with a range of new indexable inserts added to the TDMX Modular X, it is the ultimate choice for demanding drilling applications. The latest MS geometry insert now sees the TDMX platform offer three material-specific inserts. Available in diameters from 16 to 40mm, the series can undertake inclined entry and exit, stacked plates and cross-hole drilling in steel, stainless steel, superalloys and cast iron. To find out more, come and talk to one of our experts at MACH on Stand 432 in Hall 20.