A L DALTON LIMITED

Stand: 18-120

A L DALTON LIMITED

Description

Established in 1901, Daltons Wadkin are a family run business specialising in the supply and support of industrial machinery for processing a wide range of materials include metal, wood, plastics and composite materials. The company represents leading European manufacturers focusing on quality and service for its customers.

Categories

Brands

Kimla, Houfek

Address

A L Dalton LtdCrossgate Drive

Queens Drive Industrial Estate

Nottingham

Nottinghamshire

NG2 1LW

GB

Kimla BFP Linear CNC Router

The Kimla Industrial BPF CNC router takes all aspects of CNC machining to the next level. Processing speed, build quality, operating system and ease of use are unsurpassed. The multi-purpose capabilities of this CNC router make it suitable for almost any business working with wood, MDF, Plywood, aluminium and composites, cardboard, plastics and to name a few.

Houfek Maxx 8W

Designed for high production processing of metal punched/ laser-cut/ routed/ water-jet cut parts, the Houfek Maxx 8W offers both dry and wet configurations. Whether you are looking to calibrate, deburr, finish or edge round, this wide belt sander can be specified with any combination of roller disc and brush heads to deliver consistent, reliable results.

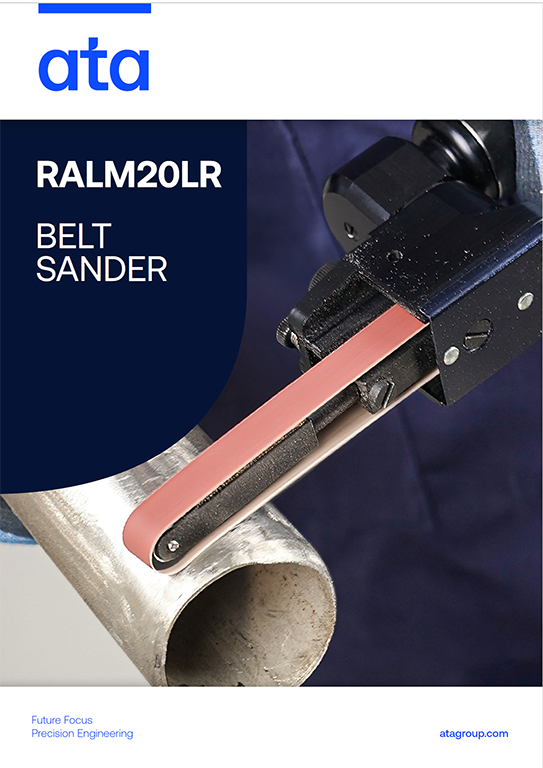

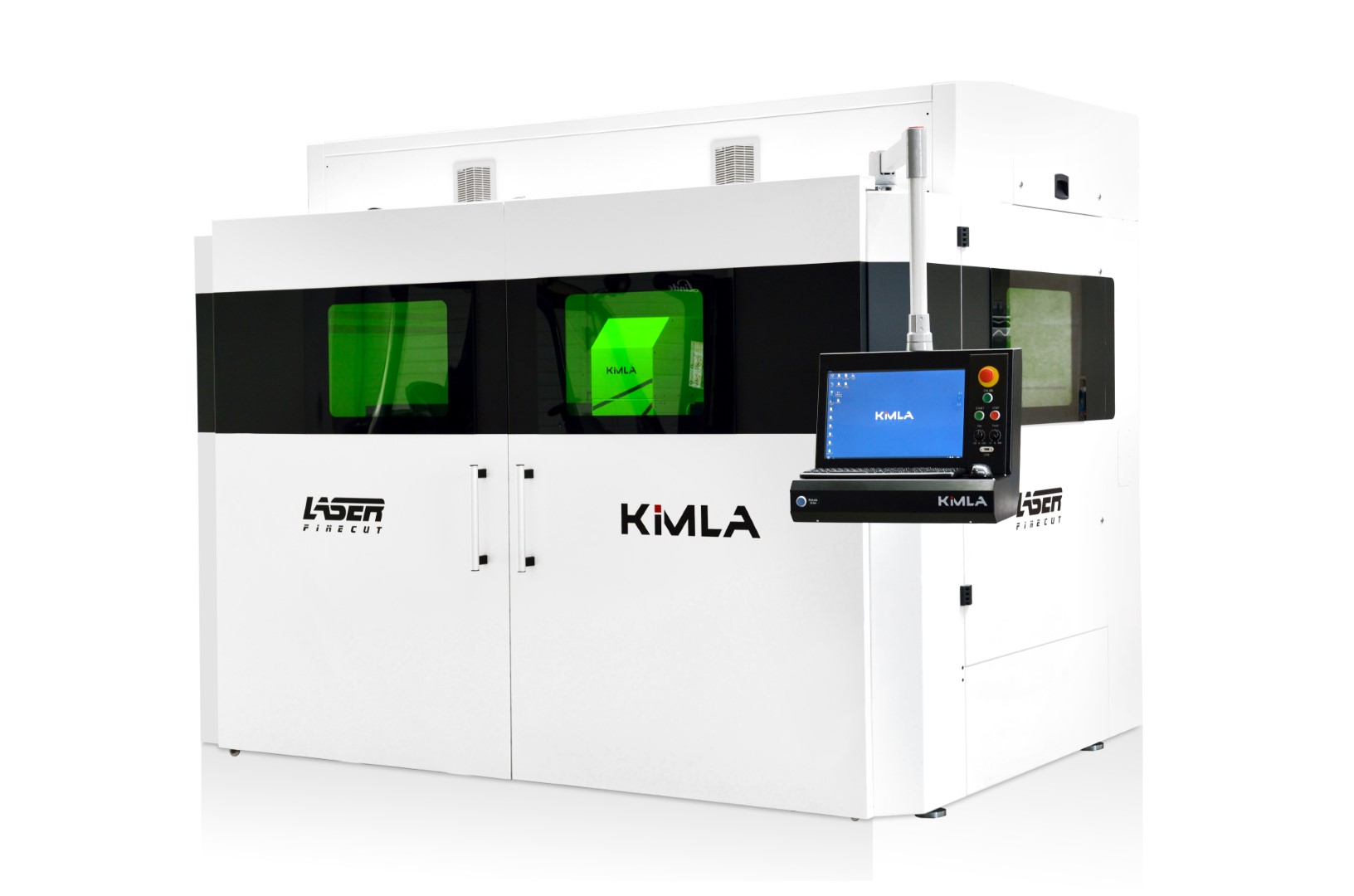

Kimla FineCut

Designed to cater for entry level production requirements, the Kimla FineCut is ideal for smaller companies looking to take their first step into fiber laser cutting. The FineCut has a compact footprint and a working area of 1000 x 2000 mm and up to 2 kW laser power and benefits from linear drives to each axis, automatic head height adjustment and anti-collision system as standard.

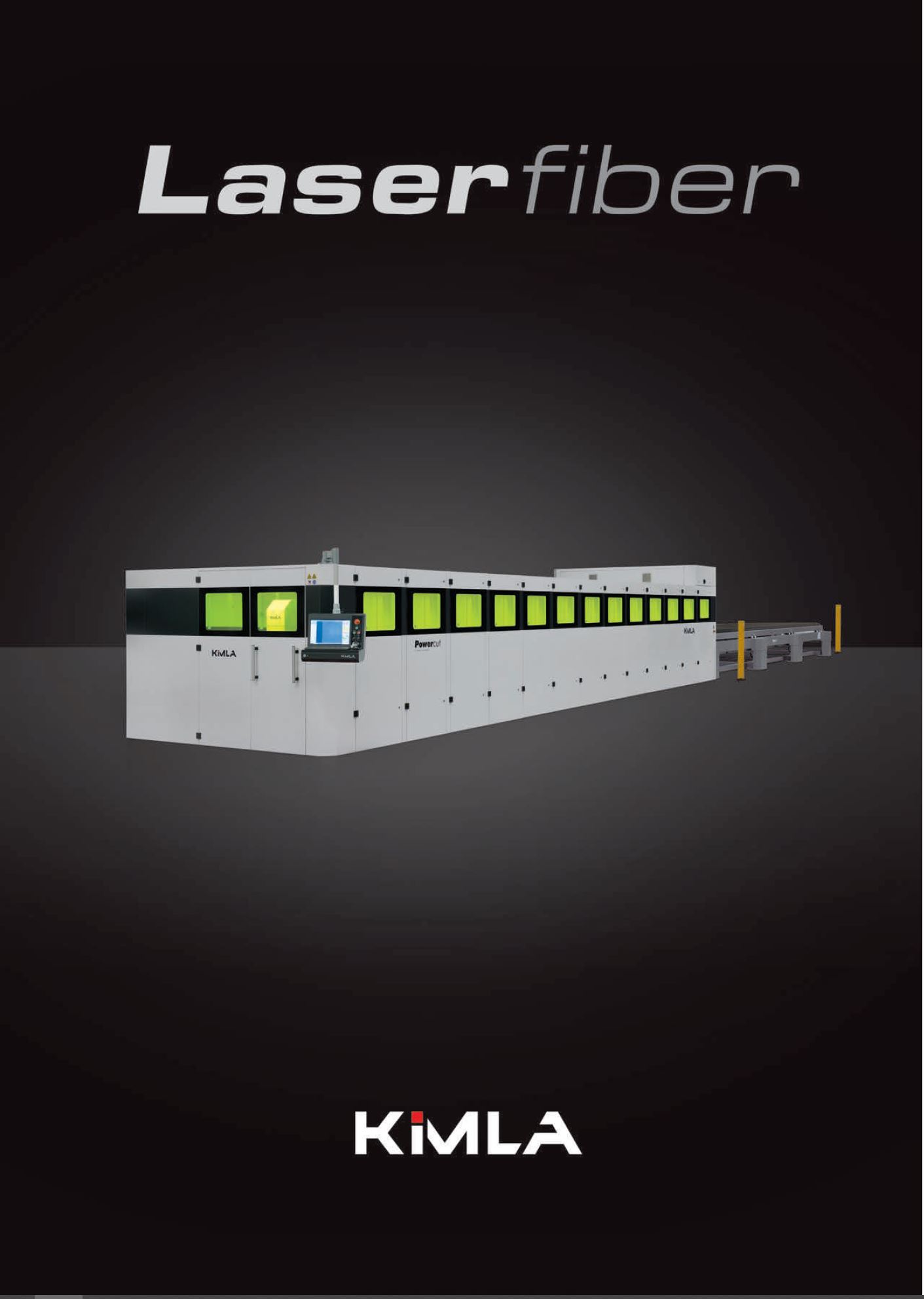

Kimla PowerCut

Truly awesome. The PowerCut delivers uncompromised performance maximising the synergy between fiber laser efficiency and Kimla’s unique CNC linear drive motion technology. With automatic pallet loading, compact operational footprint and a choice of laser powers up to 12 kW, the PowerCut is aimed at manufacturers looking for a reliable and efficient cutting system.

Kimla Fiber Lasers

DownloadABERLINK LIMITED

Stand: 19-738

ABERLINK LIMITED

Description

Since the launch of our first ground-breaking Coordinate Measuring Machine, the best-selling Axiom, Aberlink has earned a global reputation for producing a range of affordable CMMs and Optical Measuring Systems - recognised internationally for quality, accuracy, robustness, speed and ease of use.

Categories

Brands

Aberlink CMMs, Aberlink Measurement Software, Renishaw hardware

Address

Aberlink Building Vatch LaneEastcombe

Stroud

Gloucestershire

GL6 7DY

GB

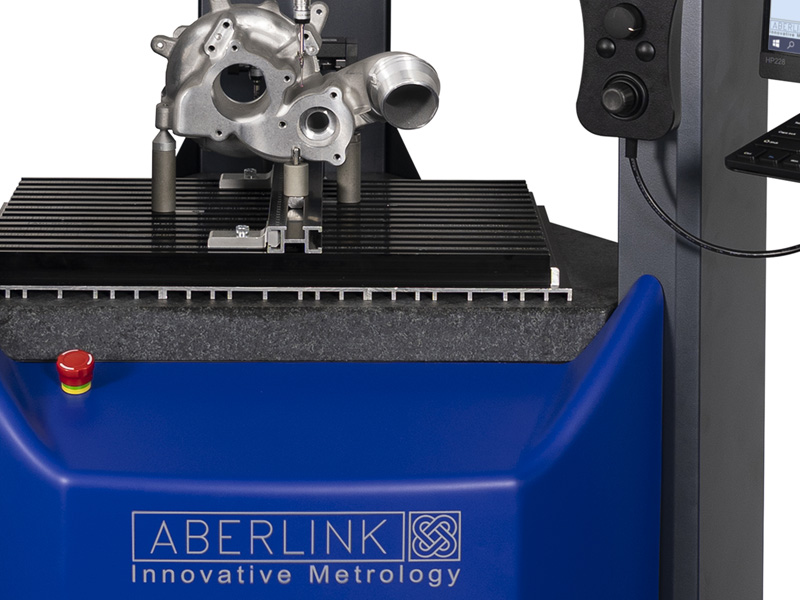

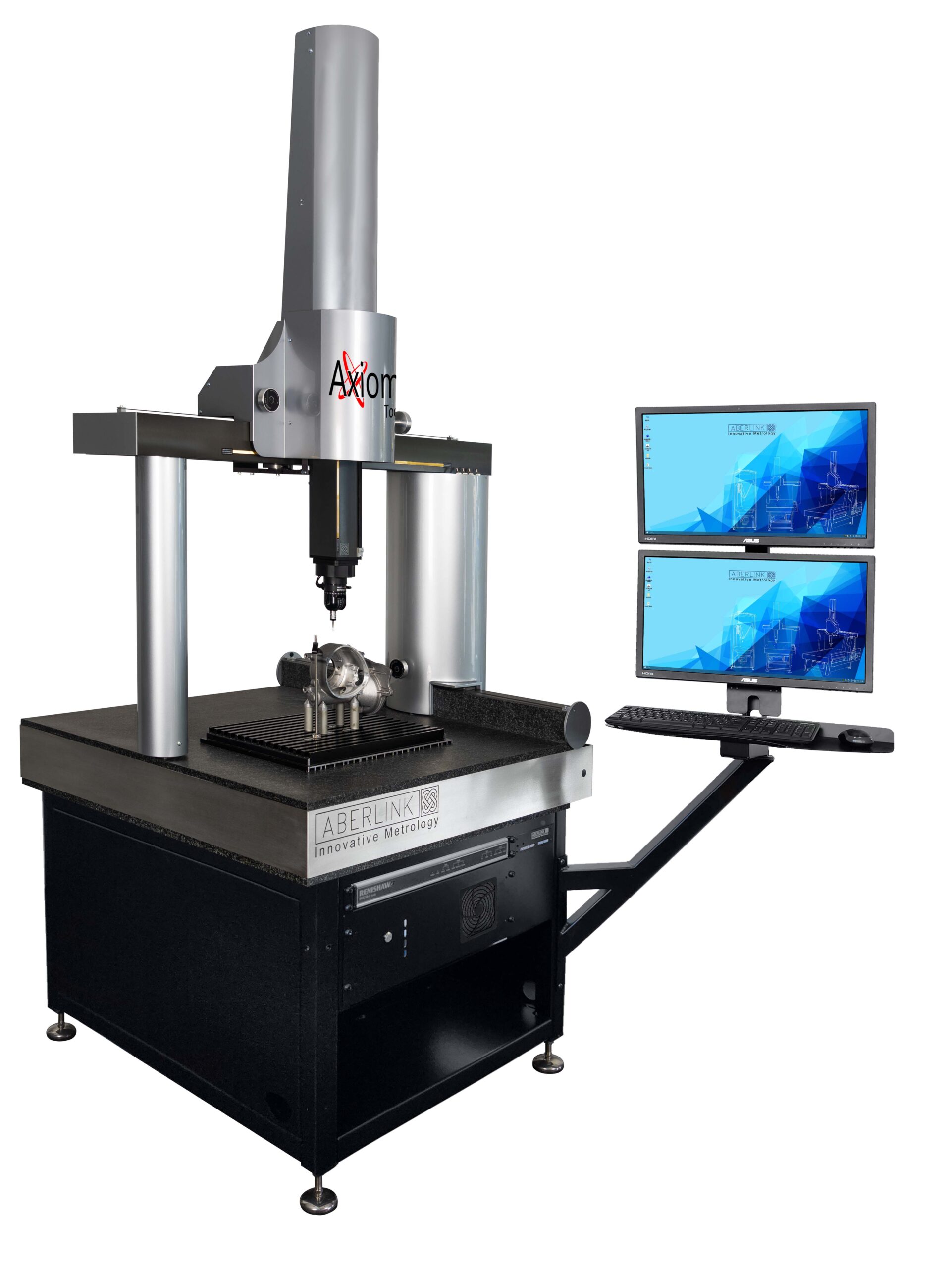

Axiom too CMM

The Complete Shop Floor Inspection System

Fast, accurate and reliable, the Axiom too CNC CMM comes in four different sizes with Y axis travel up to 1200mm. The Axiom too range of shop floor CMMs can be used with touch trigger probe, continuous contact scanning probe or with Aberlink’s revolutionary non-contact camera system.

The all aluminium bridge structure not only ensures that the Axiom too has low inertia and high acceleration to get the job done quickly, but also that the temperature of the machine rapidly follows the temperature of the room, ideal when the CMM is not housed in a controlled environment. Temperature compensation in the software reports results as if they had been measured at 20°C/68°F.

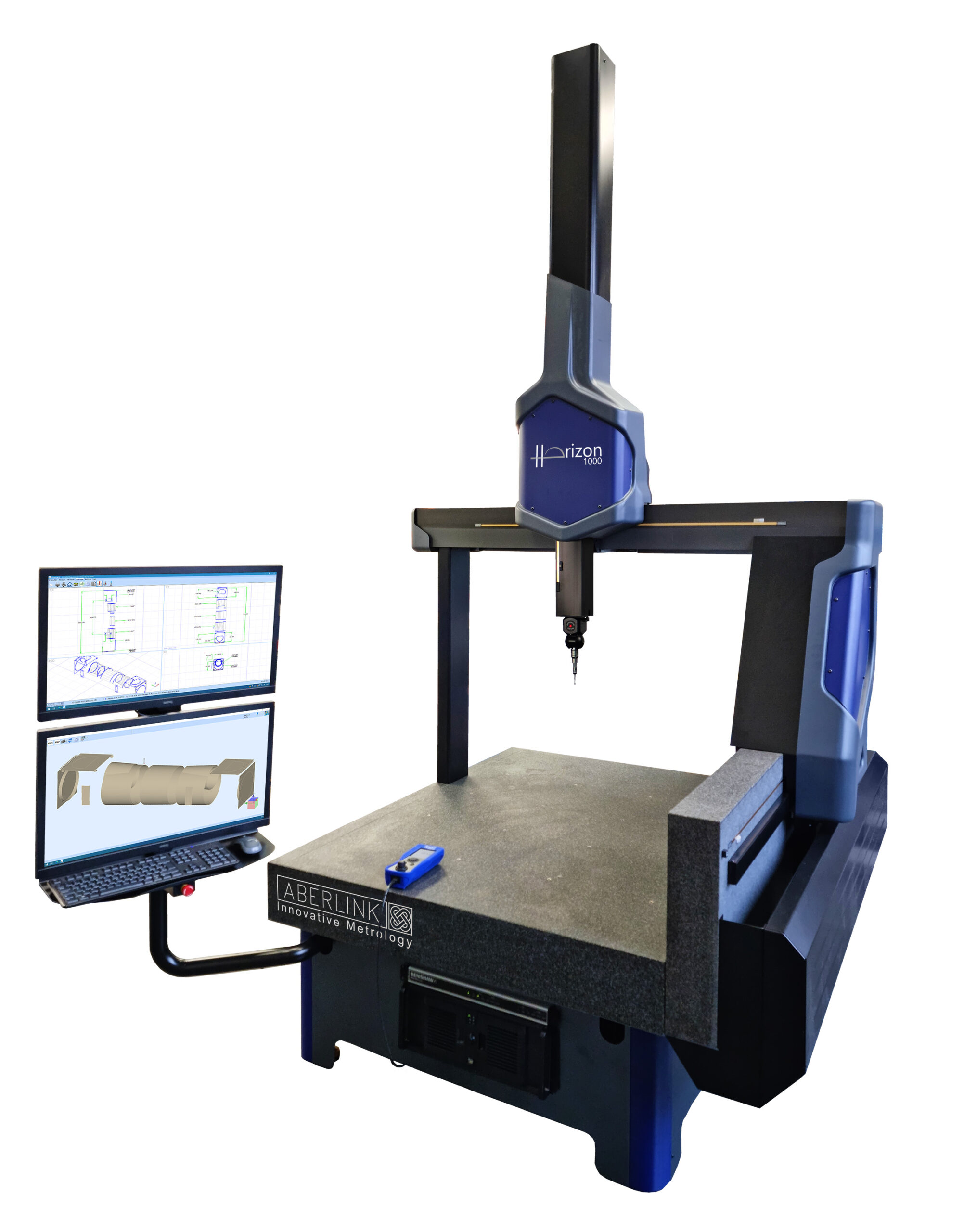

Horizon 1000 CNC CMM

Extending The Linear Drive Horizon

Drawing upon the tremendous success of the Horizon 800, the Horizon 1000 has a larger X-Y-Z axis travel whilst utilising the same frictionless linear drives.

The entire design of the Horizon 1000 has been optimised to take full advantage of parts already used on the Horizon 800 whilst improving the stiffness-to-weight ratio across the bridge assembly. Most notably: The Y-axis rail is 200mm taller so that the same right-hand-side linear drive system is common and improves rigidity; the carriage assembly has reduced in size and weight, without compromising metrology performance, to improve the stiffess-to-weight ratio; the Z-axis motor has increased power to optimise its performance; the left-hand-side air bearing assembly has a custom extruded profile to keep weight to an absolute minimum and maintain stiffness.

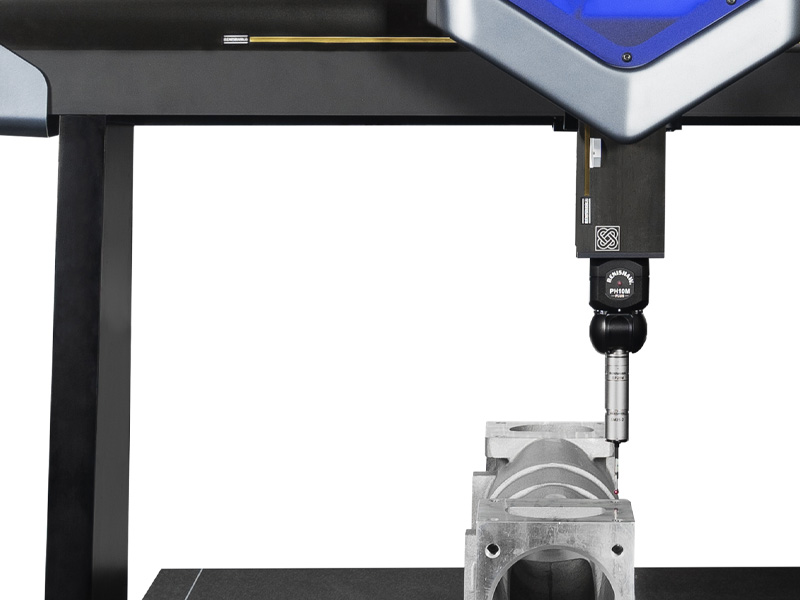

Extol CNC CMM

Next Generation Of Shop Floor Hardened, Non-Cartesian CMM

True to Aberlink's heritage for innovation, the Extol is the world's first CMM to utilise a delta mechanism.

Designed for robustness and reliability, the Extol CMM will run around the clock making it ideal whether it is positioned next to a machine tool, in a manufacturing cell, or used in a dedicated inspection area.

Five temperature sensors monitoring both the machine and ambient temperature ensure that the Extol is capable operating in uncontrolled environments and reporting measurements as though they had been taken at 20°C. The software will also produce a warning should the temperature change at a rate that is not conducive to reasonable metrology practice.

Robust, accurate, and reliable, the Extol CMM is the perfect solution to automatically verify part quality for critical components.

Fulcrum Manual CMM

Accurate Inspection Right Next To Your Machine Tool

Now supplied with a 3-year warranty!

Inspect your parts through every step of the manufacturing process.

The Fulcrum is a revolutionary manual CMM, by employing a three-rotary axis design, Aberlink has created a compact and portable design enabling it to be used where it is needed, on the shop floor near your machine tools.

Designed to optimize inspection as parts come off the machine one op at a time, feeding back to the machining process at the earliest opportunity, before final inspection, before more expense.

A simpler user interface has been developed for Aberlink measurement software, making it even easier to use on a manual CMM, while retaining full functionality. After manually scanning the part, critical features are automatically recognized, and dimensions are automatically displayed.

Intuitive software and innovative design mean you’ll be measuring your parts within minutes of switching on the Fulcrum CMM, even with no prior operating experience. It will quickly become the tool of choice for jump-on, ad-hoc inspection, whether checking 1st off inspection, small batch quality control, or setting CNC machines. The Fulcrum is the easiest CMM to learn and use.

Aberlink Product Catalogue

DownloadACCURIDE INTERNATIONAL LTD

Stand: 6-64

ACCURIDE INTERNATIONAL LTD

Description

As a global designer and manufacturer of telescopic slides and linear guides, Accuride have over 50 years’ experience developing sliding solutions.

Visit us at stand 2020 to learn about our range, including the FULLELECTRIC motorised slide, our linear motion guides and the DA1532 pocket door system for large pocket doors.

Categories

Brands

FULLELECTRIC®

Address

Liliput RoadBrackmills Industrial Estate

Northampton

Northamptonshire

NN4 7AS

GB

Heavy Duty Over Travel Slide DZ5321

Heavy duty over travel slide DZ5321with a load rating upto 140-160kg, with hold-in feature, 100% extension and 19.1mm slide thickness. Ideal for Industrial applications & wider drawers upto 1m.

Pocket Door Pack for Large Door DA1532-0070-P3-TI

Pocket door pack for large doors DA1532-0070-P3-TI containing:

1 pair of slide - Pocket door slide for large doors DA1532-0070-2

2 Hinges - Hinge Kit 40mm 81020890-A for Thick Inset Doors

1 Centre slide - DA1532-0070U

1 Bracket DS1532-BRKT

1 Damper - 40202610

1 Damper bracket - 40202810

Suitable for a maximum door height of 1200-1800mm.

Kit is for one door

If you need a variation of our DA1532 pocket door slide for a different sized door, visit our pocket door configurator to change your requirements.

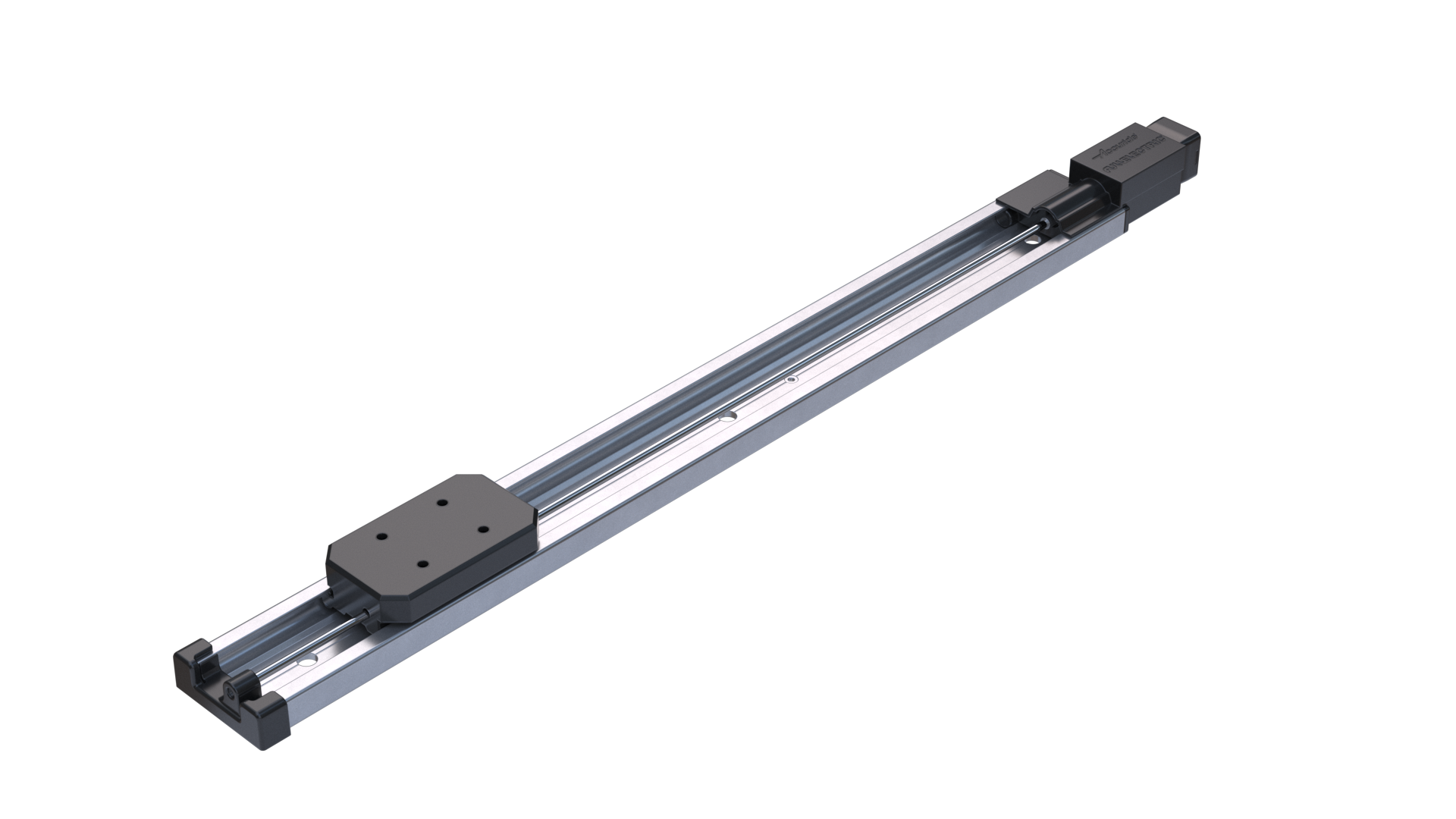

Linear Motion System DA0118RC

Linear motion track and recirculating ball carriage DA0118RC is designed to support applications of up to 375kg, with an impressive push force of just 2% of the application’s weight. Bringing smooth and accurate movement to sliding doors, vending machines, extendable worktops and assembly lines.

Full extension slide

The FULLELECTRIC® can be used as a linear actuator with existing undermount slides.

Linear Motion Slide K09 with spindle drive

Linear Slide with belt drive

Accuride DA0115 Linear Motion Track

The DA0115-RC aluminium linear motion track with recirculating ball carriages can support light duty applications with a load rating of up to 130kg, making it suitable for cabinet doors, machinery and multiple movement applications.

As an alternative to aluminium, the track is also available to purchase in stainless steel, however the stainless steel track is only suitable for light duty applications weighing up to 30kg.

Aluminum & Stainless Steel Soft-Close Heavy Duty Slide Family | #Accuride 5321

#HeavyDuty #DrawerSlides #Softclose #AccurideEurope

The Accuride 5321 is a heavy-duty slide that extends 100% of its closed length.

The 5321 also includes a detent to hold in drawers when closed.

The 5321 comes in various materials such as aluminium and stainless steel.

The 5321 also comes in multiple variants, including Self-Close and Easy-Close.

Accuride 0116RC linear motion track

Our extra heavy-duty linear motion track can support up to 600kg. The impressive linear motion track and guide is designed to support moving cranes, large sliding walls, screens and very large doors.

Introducing the Accuride Linear Track DA0118RC

Linear motion track and recirculating ball carriage DA0118RC is designed to support applications of up to 375kg, with an impressive push force of just 2% of the application’s weight.

Bringing smooth and accurate movement to sliding doors, vending machines, extendable worktops and assembly lines.

1532 Pocket Door Linear Track Video Installation Guide

The DA1532 pocket door slide is Accuride’s answer to heavy-duty wardrobes and cabinets.

Need help installing the pocket door slide? Watch our installation video.

The Accuride DA1532 Pocket Door Pack for large doors

Find out more about the Accuride DA1532 pocket door sliding system.

As the recommended pocket door slide for doors of up to 45kg, the DA1532 pocket door system has been designed with large wardrobe doors and tall room dividers in mind. Suitable for both inset and partially overlay doors, the DA1532 pocket door slide has been designed for fitters who want a high-quality pocket door slide which is easy to install.

FULLELECTRIC Slides leaflet

Customisable for your Applications

Different FULLELECTRIC® slides, with variable design (full extension, part extension, linear slide, two way travel), drive technology (lead screw, belt drive, rack-and-pinion-drive) and motor technology (stepper motor, BLDC motor or DC motor) are available.

The made-to-order slide can be customised, making it suitable for a range of automated solutions, including robot delivery systems, factory storage, luxury furniture and car interiors.

DownloadACTON FINISHING LTD

Stand: 20-480

ACTON FINISHING LTD

Description

With a legacy dating back to 1965, ActOn Finishing has emerged as a prominent family business dedicated to delivering exceptional surface finishing products and services. Throughout our journey, we have focused on designing and manufacturing high-standard solutions for mass finishing, shot blasting, waste water treatment and ultrasonic cleaning.

Categories

Brands

ActOn Finishing, DLyte, Normfinish

Address

213 Torrington AvenueTile Hill

Coventry

West Midlands

CV4 9HN

United Kingdom

Mass Finishing Consumables

We offer a range of Finishing Consumables to help our customers achieve the surface finish they need. We can cater to all your application requirements including deburring, degreasing & oil removal, cleaning, descaling, radiusing, smoothing and polishing. We will offer you full support every step of the way. Our range of consumables includes:

- Ceramic media

- Plastic media

- Agro and pre-treated media

- Shot blasting media

- Stainless steel polishing media and wood media

- Liquid finishing compound

- Powders, pastes & special compounds

- Consumables for water treatment

- Ultrasonic cleaning solutions

Wheel Blasting Machines

At ActOn we now offer a range of Wheel Blast Systems to help you achieve the surface finish you need. We can cater to all your application requirements including descaling, removal of corrosion or rust, paint stripping, de-flashing, achieving a smooth finish, shot peening, polishing and surface preparation prior to coating. We will offer you full support every step of the way.

Shot Blasting Cabinets

At ActOn Finishing we offer a wide range of shot blasting machines to help our customers achieve the surface finish they need every time. Whether you require to descale, remove corrosion, mill scale, paint or rust, achieve a smooth finish, deflash, polish or strengthen the metal we will offer you full support every step of the way.

Our range includes a Mobile Blasting Series; The ECO Blasting Series an economical range of Suction Blast,

Wet Blast and Pressure Blast machines; The Premium Blasting Series which consists of Suction Blast,

Wet Blast and Pressure Blast machines; the AM Blasting cabinets for finishing metal and polymer 3D printed parts; and Automated Blasting Machines.

Ultrasonic Cleaning Systems

ActOn Finishing Ultrasonic Cleaning Machine UK is designed to clean, descale and strip a large range of components. It's perfect for a range of industries such as automotive, aerospace, energy, electronics, food, graphics, jewellery, manufacturing, marine, mould cleaning, medical, optical and more. This technology includes a Standard Series, a Laboratory Series, the Ultrasonic Machines built for the Automotive Industry and Customised Ultrasonic Systems.

Centrifugal Disc Machine

ActOn’s Centrifugal Disc finishing machines have been designed to be reliable and easy to operate. These machines are perfect for processing small and thin components as well as larger parts with a length of 150mm.

The Centrifugal Disc Finishing Machines are recommended for processing small to medium batches of parts. The spinning motion of the disc machine is given by the disc situated at the bottom of an open barrel. The rotating disc makes the media, compound and parts to move in a rolling motion, resulting in a effective finishing process in the shortest time.

Centrifugal High Energy Finishing Machine

ActOn’s Centrifugal High Energy Finishing machines are possibly the most efficient of the finishing systems available in the industry. These machines generate a very high gravitational force and are designed to maximise the output.

In many cases, the results achieved via CHE Finishing cannot be achieved in a standard vibratory process. Particularly applications that include achieving a high surface finish requirement, a mirror finish and the removal of heavy manufacturing defects. Parts that require hand finishing are excellent candidates for High Energy Finishing. These machines can be 10 times faster than vibratory finishing, producing superior finishes.

Which mass finishing media is best to use in a finishing process?

Not sure where to start when it comes to choosing the right mass finishing media for your finishing process? That’s where we can help, join us as we explore the essential factors to consider when selecting the best media for your specific needs in our video.

ActOn Dry & Wet Shot Blasting Cabinets

At ActOn Finishing we offer a wide range of dry and wet shot blasting machines to help our customers achieve the surface finish they need every time. Whether you require to descale, remove corrosion, mill scale, paint or rust, achieve a smooth finish, deflash, polish or strengthen the metal we will offer you full support every step of the way.

ActOn ABC01 Batch Centrifuge – Waste Water Treatment Solutions

ActOn ABC01 Batch Centrifuge is designed to work in the most effective manner to treat the waste water from mass finishing, either suitable for recycling or discharge to the foul drain as dictated by the process.

The solids are captured in the basket of the centrifuge and then disposed of based on country specific regulations.

Vibratory Finishing Bowls vs Vibratory Troughs: Which one should you use for processing parts?

While vibratory finishing bowls can finish high volumes of parts per batch, vibratory troughs are ideal for large, long or irregular shaped components that cannot fit through the bowl's chamber.

Want to better understand the differences between vibratory bowls and vibratory troughs, their benefits and features? Join us as we discuss all of this to help you decide which one your business should use for processing parts in our video.

CHEF Machines vs Conventional Finishing Technology – Learn How to Achieve a Finish 10 Times Faster

ActOn’s CHEF (Centrifugal High Energy Finishing) machines are possibly the most efficient of the finishing systems available in the industry. In many cases, the results achieved via CHE Finishing cannot be achieved in a standard finishing process. Particularly applications that include achieving a high surface finish requirement, a mirror finish and the removal of heavy manufacturing defects. These machines can be 10 times faster than vibratory finishing, producing superior finishes.

Join us as we discuss the benefits of CHEF technology and more in our video.

Special EFX Testimonial – Pressure Blast Cabinet Improves Sand Blasting Process Time & Part Finish

At ActOn Finishing we offer a wide range of dry and wet shot blasting machines to help our customers achieve the surface finish they need every time. Whether you require to descale, remove corrosion, mill scale, paint or rust, achieve a smooth finish, deflash, polish or strengthen the metal we will offer you full support every step of the way.

ADDITIVE X

Stand: 17-520

ADDITIVE X

Description

Additive-X are Additive experts! We provide companies with unbiased advice about where to start, how to grow and innovate with 3D printing as well as maximizing commercial returns.

Product Profile: 3D Metal Printing, 3D Print Bureau, 3D Printing/Printers, SLA and CFR and FFF 3D Printing, SLS 3D Printing.

Categories

Brands

Formlabs, Markforged, Lynxter, Bambu Lab, AMT, Builder, UltiMaker, 3DGence, Mayku.

Address

The College Business ParkKearsley Road

Ripon

North Yorkshire

HG4 2RN

United Kingdom

Markforged Mark Two

Introducing The Mark Two.

The Mark Two is a 3D printer for serious engineering and manufacturing applications. This is the first 3D printer in the world capable of printing composite materials with a heat deflection temperature of 140°C. So in addition to being able to reinforce nylon parts with continuous strands of carbon fibre, Kevlar and regular fibreglass, you can now reinforce parts with high-temperature materials like polycarbonate.

The Mark Two offers limitless possibilities.

Whether you are an engineer operating in aerospace, aviation, automotive, biotechnology, construction, marine or transport, or a manufacturer producing high-strength end-use parts and prototypes, the Mark Two is the 3D printer you’ve been waiting for. Parts that are reinforced with composite are as strong as 6061 aluminium and the Mark Two can reinforce features 15x smaller than the Mark One, boosting its applications considerably.

Markforged X7

Introducing the Markforged X7 - the most powerful composite 3D printer on the market. This 3D printer offers uncompromised strength and precision, with industrial-grade mechatronics and breakthrough technologies which transcend those on the market today.

Print with Markforged's full range of Composite Base materials and Continuous Fibers.

The X7 can print with Nylon or Onyx (ESD/FR) as the core build material, and can reinforce parts with Carbon Fiber, Fiberglass, Kevlar, High Strength and High Temperature Fiberglass and Precise PLA. Parts that are reinforced with a composite can be as strong as 6061 aluminum.

Print Enormous and Hugely Detailed Parts

The large build volume of the X7 makes it ideal for creating large-scale parts that currently only metal machining processes can handle. With the ability to print parts up to 330mm in width, 250mm in depth and 200mm in height, the X7 offers designers and engineers are real-world alternative to traditional manufacturing techniques. And with a 50-micron print resolution, your parts will come out with a beautiful finish, perfectly capturing the contours, details and textures you design or scan for print.

Markforged FX20™

The Markforged FX20 is the biggest, fastest, and most sophisticated 3D printer Markforged have ever built. It brings the Digital Forge and Continuous Fibre Reinforcement to a new realm of parts, problems, and industries.

Massive Builds, Faster

The FX20 pairs size and throughput to make larger builds at incredible speeds, delivering the transformational benefits of The Digital Forge at a new scale. At 4.7 times larger than the Markforged Industrial Series and three nozzles (two plastic, one fibre) you can see why it's been nicknamed 'The Beast'!

It features an 84L heated build chamber and massive, verified-flat vacuum bed with print sheets.

The motion control system offers closed loop control through precision linear encoders, and is tuned to move the 3kg print head rapidly and accurately.

FX20’s turbo mode builds parts faster than any Markforged machine, while new XL spools offer four times the material without spool changeover.

Markforged Metal X

The Metal X System is the most accessible way to fabricate complex metal parts in the widest variety of advanced metals.

From the company that revolutionised carbon fibre, Kevlar and fibreglass 3D printing comes a new breakthrough in metal 3D printing. The Metal X is a metal 3D printer that utilises a process called Metal FFF to print parts. This process uses metal powder and bulk sintering to create true-to-design solid metal parts, that can be made from a wide range of metals including Copper and 17-4 stainless steel.

The Metal X - The Ultimate Metal 3D Printer

The Metal X has a build volume of 300 mm x 220 mm x 180 mm (WDH) with an enclosed build chamber. It can print down to a layer height of 50-microns, and the user can make use of honeycomb infills and other geometries which would be impossible with subtractive and traditional manufacturing processes.

Metal FFF

3D printing metal parts has never been simpler than with the Metal X. Metal FFF prints your part using a bound metal powder surrounded by plastic. The plastic is then dissolved, and the metal powder sintered. The resulting parts are solid metal, with the same strength and durability as metal parts that have been cast.

The Metal X can 3D print several metals, including: 17-4 Stainless Steel, H-13 Tool Steel, 6061 Aluminum (Beta), 7075 Aluminum (Beta), A-2 Tool Steel (Beta), D-2 Tool Steel (Beta), Copper, IN Alloy (Inconel) 625 (Beta) and Titanium Ti-6Al-4V (Beta). The metals with beta next to them are currently in the last stages of testing, and will be approved for customers soon.

AMT PostPro DP PRO

The AMT PostPro DP PRO is the solution for cleaning or shot blasting parts hour after hour, eliminating time and cost-consuming interventions in your post-processing chain. It is ergonomically designed and equipped with features to increase your throughput.

Cleaning millions of parts

The generously sized basket, allows for optimization of the blasting angle, cleaning parts fast, while also allowing to easily switch between batches. Once you have found the ideal recipe for blasting your parts, you can store the settings, and reuse them again and again.

Large parts, small parts

PostPro DP PRO has a dedicated manual blasting area that allows fast blasting of large parts without changing anything in your automated blasting area. Again, nothing should stop you from successfully cleaning your parts.

User-friendly

PostPro DP PRO is designed with the operator in mind. It allows for a safe, sustainable and efficient user experience. It will prepare you for the next step in the post-processing chain.

DESIGNED SPECIFICALLY FOR ADDITIVE MANUFACTURING INDUSTRY

UltiMaker S7 Pro Bundle

The UltiMaker S7 Pro Bundle adds the Material Station to our newest S series 3D printer, transforming it into a manufacturing powerhouse. This one-of-a-kind upgrade further simplifies the 3D printing worklow with automatic switching of up to 6 spools. And constant humidity control ensures material is delivered in perfect condition for high-quality 3D prints.

Key Features

The Material Station enables the UltiMaker S7 to deliver 3D printed parts at maximum output. It does this by increasing uptime and minimizing the time operators need to spend at the printer.

The Material Station allows the S7 to print longer and been designed and tested to be left unattended

The UltiMaker S7 Pro Bundle optimizes the delivery of 3D printing materials so you don't have to. Perfect humidity control, reliable filament switching, and end-of-filament detection avoid human error and increase print quality.

The Material Station integrates with the UltiMaker S7, Cura, and the Digital Factory. It's never been easier to load and print with almost any combination of polymers and abrasive composites to unlock more 3D printing applications.

ADVANCED GRINDING SOLUTIONS LTD

Stand: 20-380

ADVANCED GRINDING SOLUTIONS LTD

Description

Our range of high precision grinding and finishing machinery incorporates the very latest technological advances in machine tool design and process development.

We are your partner for providing truly innovative, economical, efficient, and world class forward thinking solutions to give you the crucial competitive advantages that you need.

Categories

Brands

Rollomatic, Tschudin, Comat, Krebs and Riedel, Bahmuller, FLP, Gerber, GPA Innova, HandlingTech, Magnetfinish, Nova, Platit.

Address

Unit 80 Hotchkiss WayBinley Industrial Estate

Coventry

West Midlands

CV3 2RL

United Kingdom

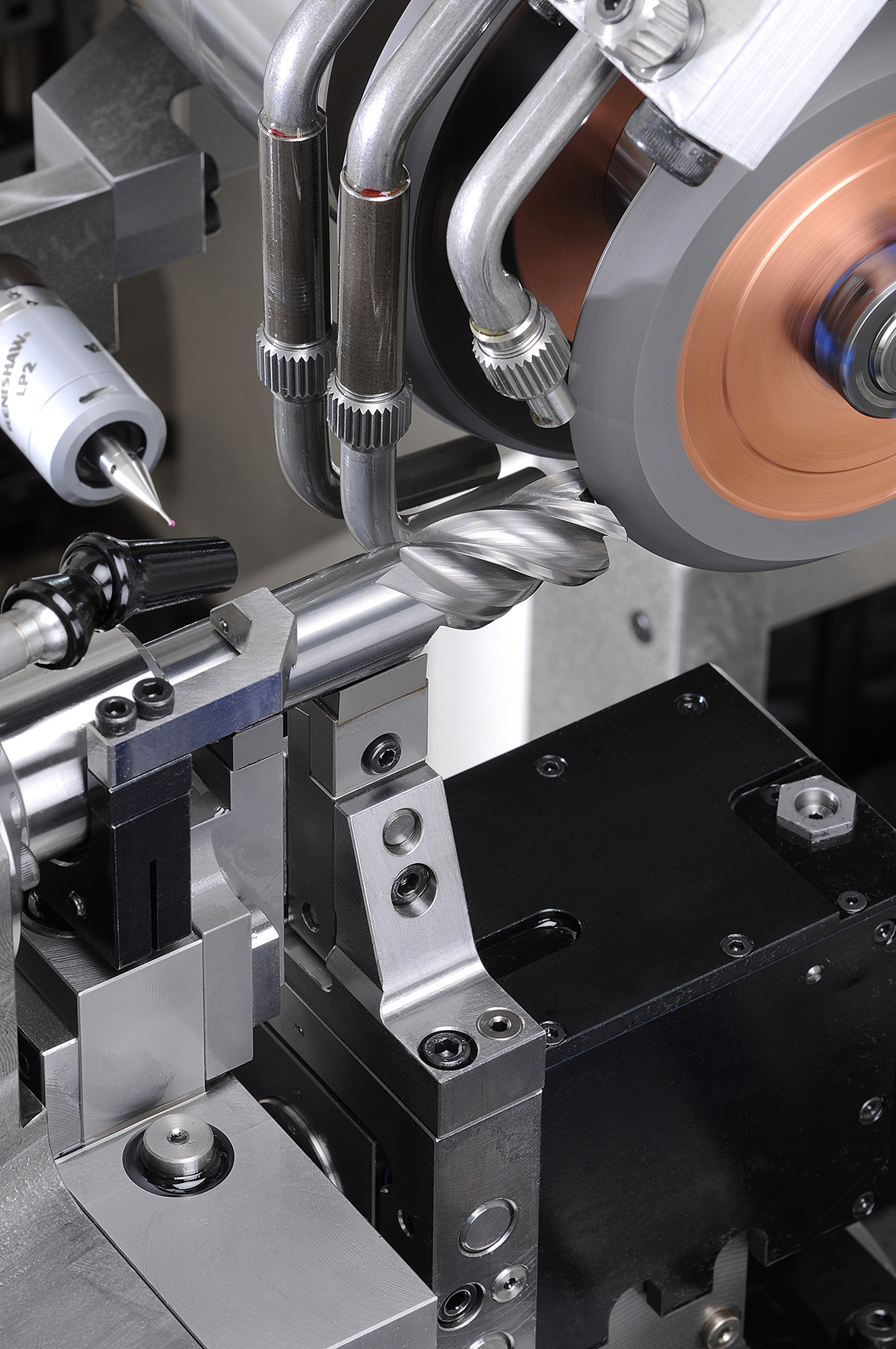

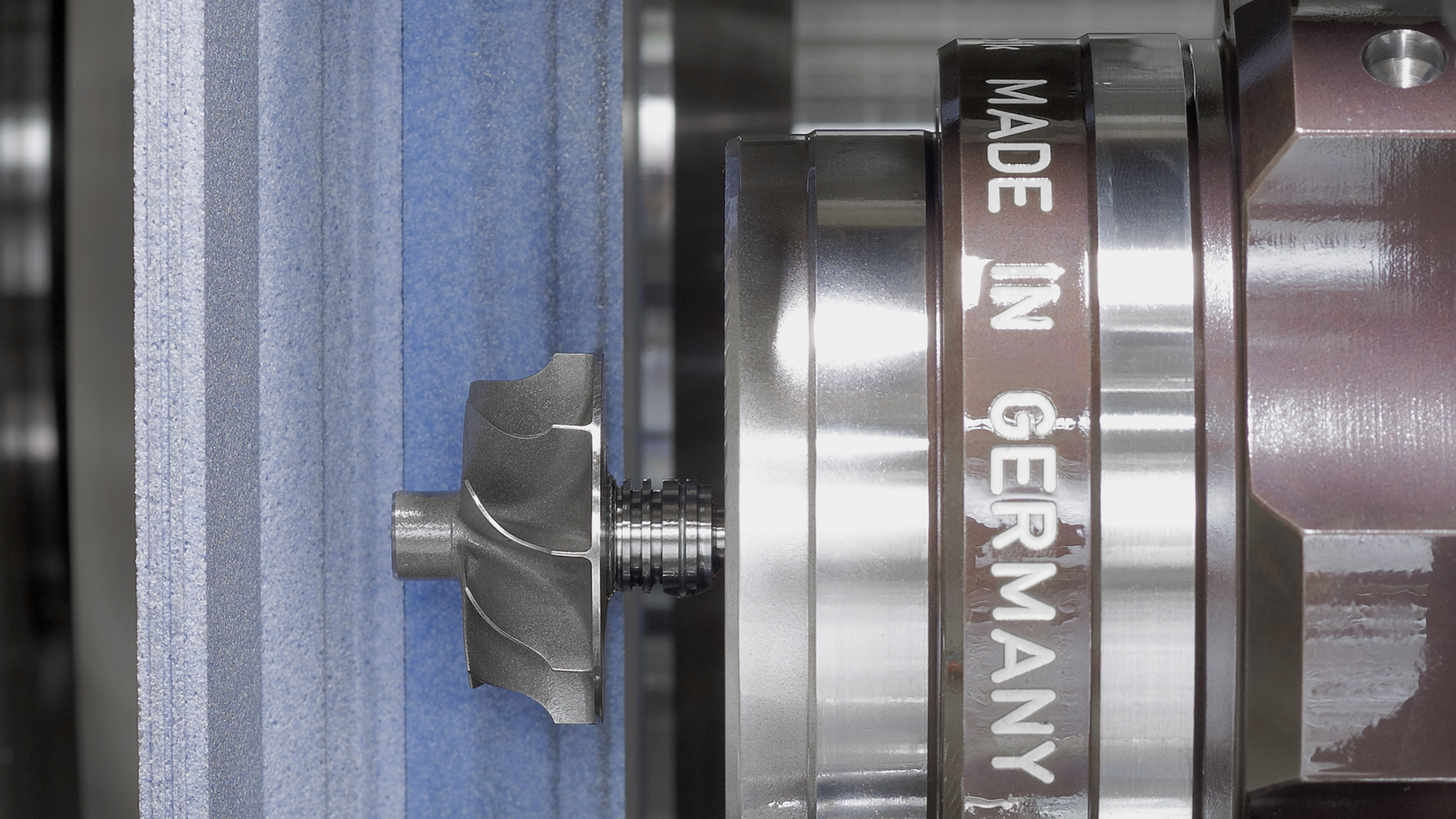

Rollomatic CNC Tool Grinding Machines

Rollomatic, one of the best known, most successful, and highly respected manufacturers of multi- axis CNC grinding machines, is the machine of choice for the production of rotary cutting tools of all kinds and for non-round tools such as punches.

GrindSmart®machines excel at producing cutting tools of up to 20mm in diameter, and the superior Swiss manufactured quality of every Rollomatic machine is demonstrated with their industry leading 3-year unlimited hours parts and labour warranty that comes as standard on all new Rollomatic machines.

GrindSmart® machines are available with a 6th CNC axis to ensure perfect tool geometry because the contact point of the grinding wheel remains constant over the entire grinding path during production. The latest linear motor technology provides more benefits such as enhanced surface finishes and reduced maintenance costs.

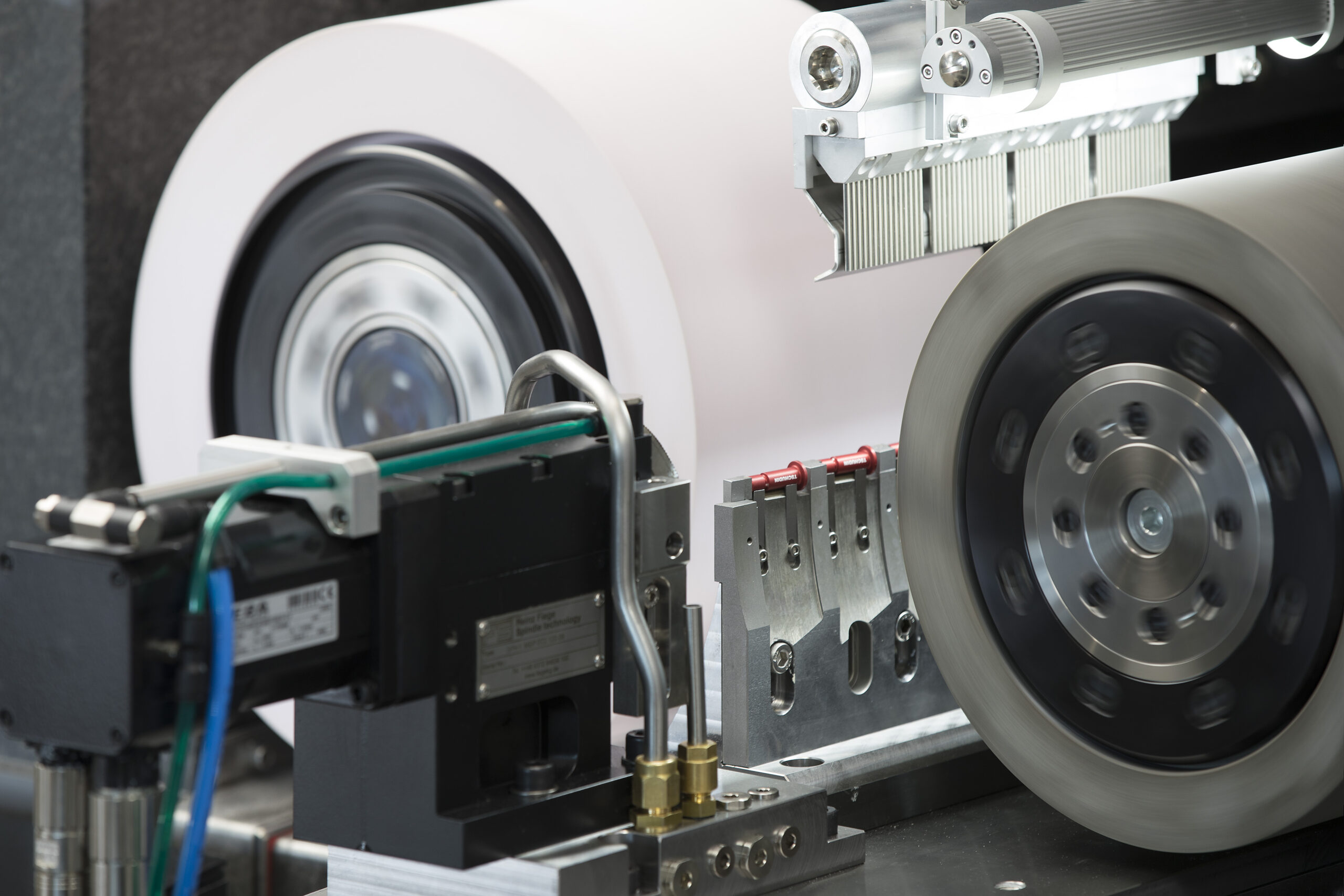

Rollomatic Blank Prep / Punch Cylindrical Grinding Machines

Rollomatic’s ShapeSmart® machines are ideally suited for the high performance cylindrical infeed grinding of cutting tool blanks such as drills, form tools, reamers, end mills, and punches. The ShapeSmart NP3 variant offers tool concentricity after grinding of within 0.002mm. These machines use a unique grinding process developed by Rollomatic known as "Pinch and Peel Grinding" for the production of cutting tool blanks or punches with diameters from 0.025mm up to 25mm and lengths of up to 330mm.

The ShapeSmart NP50 variant is able to grind many non-round forms such as ellipses, eccentric shapes, flats, squares, triangles or hexagons as needed on many punches. Punches are ground complete in a single automatic operation using both rough and finish grinding wheels allowing large stock removal and perfect ground finishes.

Bahmuller Internal, External and Universal Grinding Machines

Founded in 1945 in Pluederhausen, Bahmuller produces internal, external, and combined universal grinding machines of the very highest precision.

Bahmuller is an industry leading machine tool manufacturer providing turn-key production solutions and specialises in the development of ultra-modern technologies for high-precision grinding systems for diesel injection units, hydraulics, turbo chargers and other highly precise mass-produced components.

The wide range of internal, external, and combined grinding machines is successfully used worldwide and its Bahmuller’s continuous mission and main focus to provide all customers with leading edge technology for their demanding manufacturing requirements.

FLP Fine Grinding & Lapping Machines

The broad range of FLP fine grinding and lapping machines includes for both twin wheel - double sided CNC Lapping Machines and also single sided Lapping machines. The size of machines ranges from the most basic of 400mm in diameter having three working stations up to the world’s largest 100 ton 4-meter diameter monsters.

FLP also offers used machines, often from stock, that have been rebuilt to an as-new standard as well as supplying replacement spare and wear parts for all Lapping and fine grinding machines of every make or model. Regardless of the type and size of a customer’s old fine grinding, flat honing, lapping or polishing machine – FLP will carry out process and technology orientated improvements and general overhauls of your machines for you.

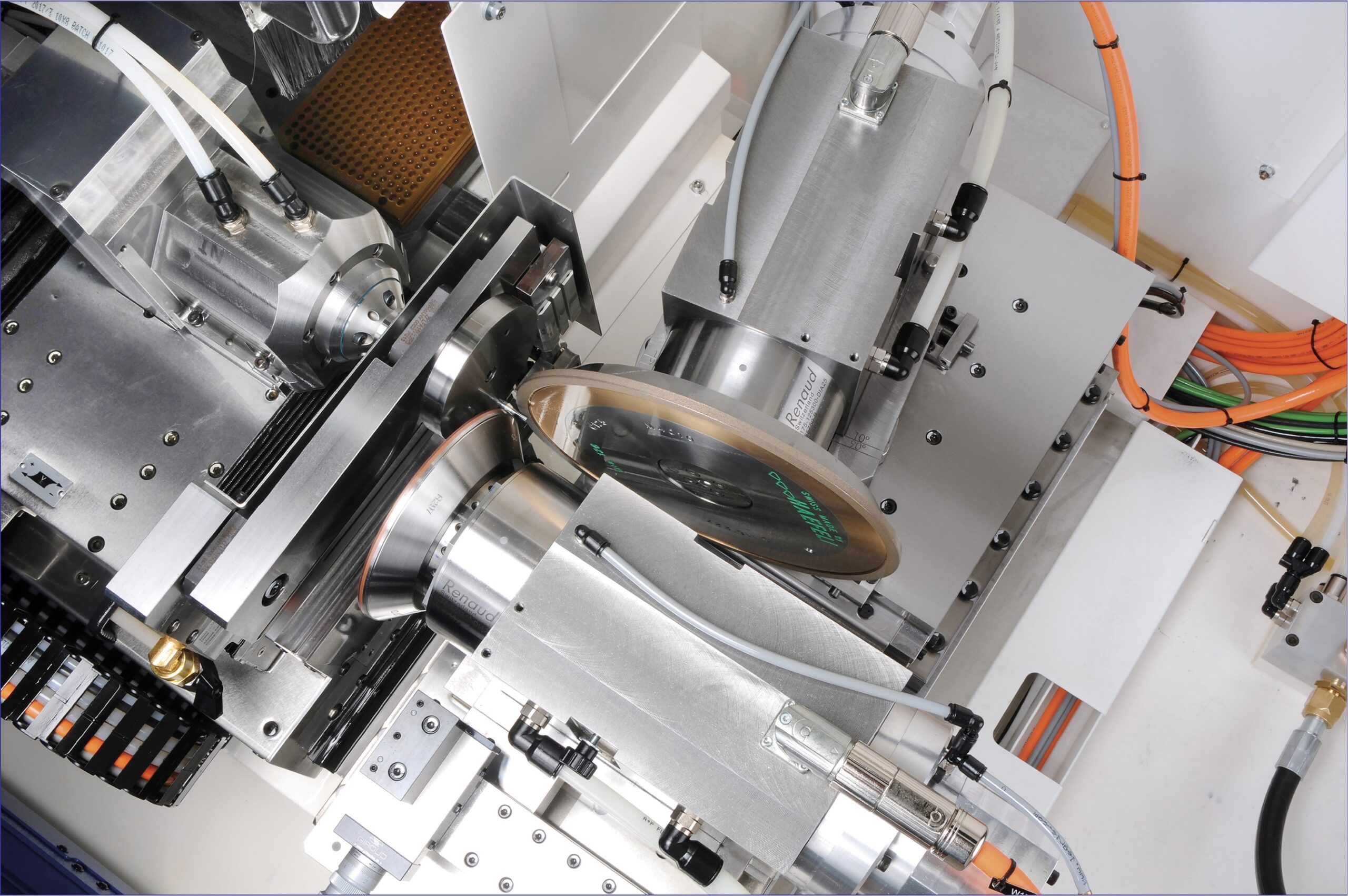

Tschudin Centerless Grinding Machines

Tschudin – One of the greatest names in grinding – continues to explore new advances in centerless grinding technology. The Tschudin machines benefit from several patented features that give them major advantages over any other machines in their class and today the Tschudin Cube machine is stated as being the world’s easiest, simplest and fastest CNC centerless grinder to set-up.

A unique feature on all Tschudin machines is also the patented movable workrest axis (W-Axis) which allows for additional grinding processes such as the highly efficient multi part grinding of several parts at a time or to split up grinding processes in the same grinding cycle to have both a rough and also a finish grind operation in one automatic set-up. Thanks to the W-axis, the loading and unloading of the workpieces is always outside of the grinding zone, allowing simplified and safe automation or safe manual loading. This feature is highly attractive for those looking to meet health & safety obligations because otherwise the hand loading of parts to centerless grinding machines can be very dangerous.

Krebs & Riedel Grinding Wheels

Krebs & Riedel who were founded in 1895 have been manufacturing high quality conventional, diamond and CBN abrasives for well over 100 years and we are able to count leading UK engineering companies such as Perkins Engines, Grundfos and Delphi Diesel Systems amongst our ever growing customer base. Krebs & Riedel who employ approx. 250 people and have a turnover of around £35m are constantly introducing new types of wheels with improved grain structures and novel bonding systems that enhance grinding wheel quality and optimise performance.

Diamond and CBN wheels that have been manufactured by Krebs & Riedel for more than 20 years are available from 3mm to over 900mm in diameter with peripheral grinding speeds of up to 160 m/s. We are also supplying UK customers many small diameter CBN wheels for jig grinding applications. These special CBN wheels are supplied in a variety of sizes, usually from 5 – 35mm in diameter in small batch sizes as low as 3 off. These can be supplied unmounted or pre-mounted onto high precision jig grinding mandrels as specified by the end user.

No videos provided.

AGS General Brochure

DownloadAIR PRODUCTS PUBLIC LIMITED COMPANY

Stand: 19-508

AIR PRODUCTS PUBLIC LIMITED COMPANY

Description

Air Products is a world-leading industrial gases company in operation for over 80 years focused on serving energy, environmental, and emerging markets. Air Products’ base business provides essential industrial gases, related equipment and applications expertise to customers in dozens of industries, including refining, chemicals, metals, electronics, manufacturing, and food.

Categories

Brands

Gastrak® Service, Integra®, Maxx® gases, CryoEase®

Address

2 Millennium GateWestmere Drive

Crewe

Cheshire

CW1 6AP

United Kingdom

Integra e2

Gastrak e2

Air Products brochure for MACH2024

DownloadAKYAPAK ULUSLAR ARASI DIS TICARET MAKINA SANAYI VE

Stand: 20-370

AKYAPAK ULUSLAR ARASI DIS TICARET MAKINA SANAYI VE

Description

We are a machinery company that connects technology and engineering through comprehensive machinery and software solutions for metal forming and fabrication. Our innovative products and services, backed by our global dealer network, provide exceptional value that helps our customers succeed and empowers industries to contribute to a better and sustainable future.

Categories

Brands

No brands provided.

Address

Hasanağa Osb Mah.Hosab Sanayi Cad. No: 62

Nilüfer

Türkiye

16280

TR

AHS-RK – 4 Roll Wind Tower Rolling Line

The AKYAPAK AHS-RK Wind Tower Production Line is specifically designed to provide customized solutions for the wind energy industry. Having amassed 62 years of experience and advanced engineering expertise, Akyapak has differentiated itself from market competitors. Its wind tower bending lines, designed to seamlessly integrate with in-house developed and manufactured welding solutions, are utilised alongside column-boom systems and rotators to boost productivity via enhanced speed and automation. This contemporary system, with its high production capacity, significantly enhances the efficiency of your work.

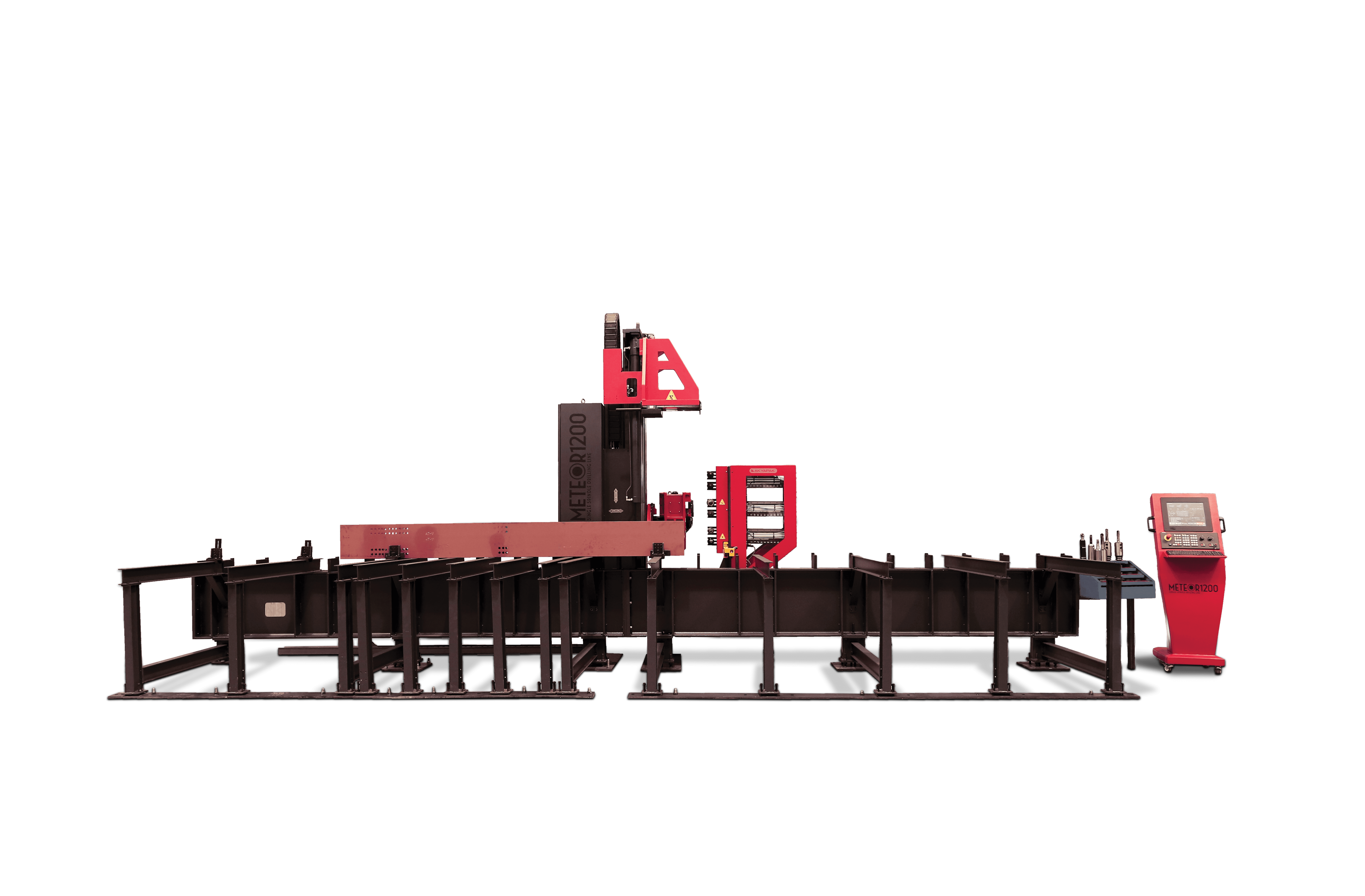

METEOR – Single Spindle Drilling Line

Minimum Downtime, Maximum Output

The METEOR is a compact, versatile machine designed for small to medium-sized fabricators seeking to enhance efficiency and space utilization. It supports a wide range of steel profiles including beams, angles, and flat sheets, and is equipped with both drilling and milling capabilities for high precision in creating slots. A key feature is its innovative sub-axis design, allowing horizontal spindle movement over a 250 mm range for accurate positioning without moving the entire machine. This enhances operational efficiency and accuracy, making the METEOR a valuable tool for improving productivity and work quality in metalworking projects.

3 ADM 1200 – 10 Axis Three Spindle Beam Drill Line

The 3 ADM is an advanced three-spindle, 10-axis CNC beam drill line, innovatively designed to process materials up to 20” (500mm) in length without the need for repositioning. This allows for the independent control of each spindle, significantly enhancing flexibility and efficiency in operation. Unlike conventional drill lines, the 3 ADM excels in performing multiple operations concurrently including drilling, marking, tapping, and milling on various sections of a beam. This is facilitated by the independent movement of each spindle along three axes, making it possible to execute different tasks simultaneously on separate parts of the workpiece.

No videos provided.

No brochures provided.

WASTE MISSION

Stand: 6-539

WASTE MISSION

Description

Waste Mission, a trusted partner in industrial waste management, began its journey in the UK in 1985 as metal recycling company, Alchemy Metals. Over the past 40 years, we’ve strived to make the world a shade greener, turning complex waste challenges into simple, sustainable solutions.

Categories

Brands

No brands provided.

Address

Cavendish PointCavendish Road

Stevenage

Hertfordshire

SG1 2EU

GB

No products provided.

No videos provided.

No brochures provided.

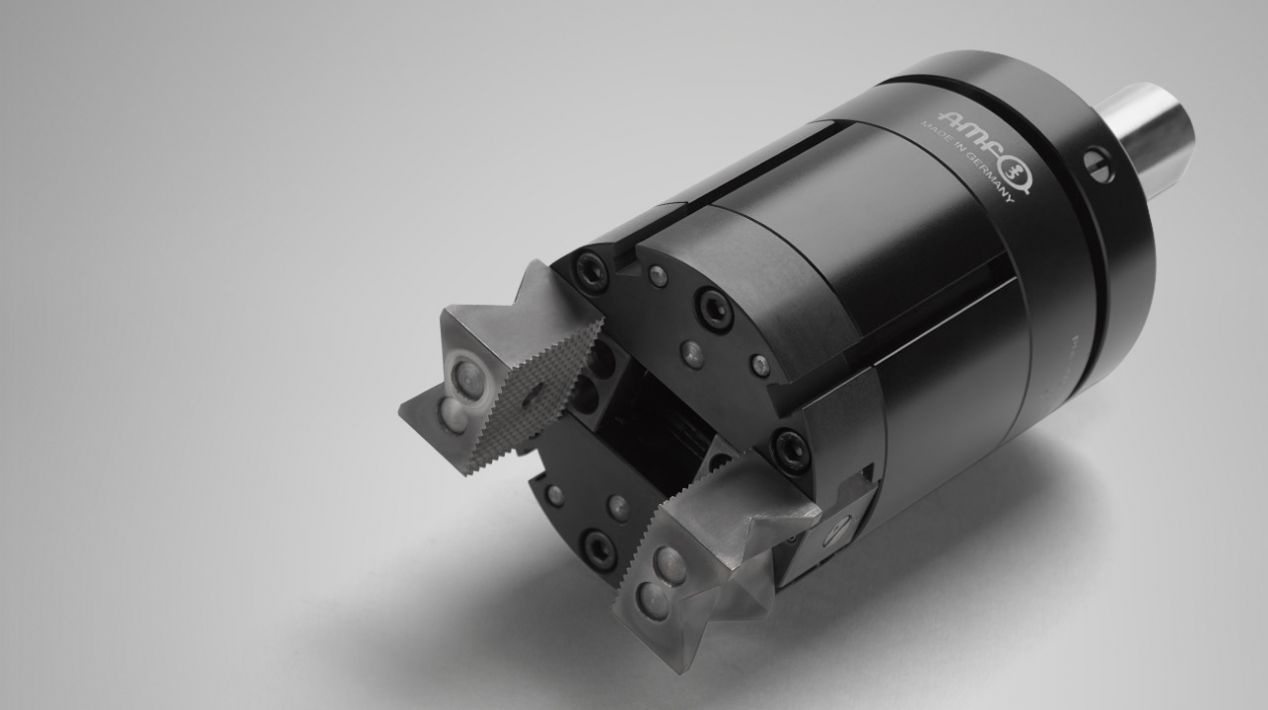

ALLIED MACHINE & ENGINEERING CO. (EUROPE) LTD.

Stand: 6-280

ALLIED MACHINE & ENGINEERING CO. (EUROPE) LTD.

Description

Allied Machine + Engineering is a worldwide leader in holemaking and finishing solutions. With over 75 years of experience, we have encountered the challenges of growth and success. By investing in cutting edge technology, our knowledge and capabilities continue to expand and grow every day.

Categories

Brands

GEN3SYS XT & XT Pro, T-A & T-A Pro, APX Drill, 4TEX Drill, Revolution Drill, Opening Drill, AccuPort 432, BT-A Drill, ALVAN Reamers, SCAMI Roller Burnishing, WOHLHAUPTER Boring Systems, AccuThread 856, ThreadMills USA.

Address

93 Vantage PointPensnett Estate

Kingswinford

West Midlands

DY6 7FR

GB

No products provided.

No videos provided.

No brochures provided.

AMOB MACHINERY LIMITED

Stand: 6-170

AMOB MACHINERY LIMITED

Description

AMOB UK is a leading provider of advanced tube bending solutions and metal forming machinery. With a history spanning decades, AMOB's innovative equipment and expert engineering cater to diverse industries, delivering high-quality results. We are committed to precision, quality, and client success, making AMOB UK a trusted industry partner.

Categories

Brands

No brands provided.

Address

Unit 6a, Pilot Trade CentrePilot Drive

Pilot Trade Centre

Coventry

West Midlands

CV3 4RS

GB

No products provided.

No brochures provided.

ANDREAS MAIER GMBH & CO. KG

Stand: 17-02

ANDREAS MAIER GMBH & CO. KG

Description

HOME OF CLAMPING

Founded in 1890 as Andreas Maier Fellbach, AMF today is a one-stop supplier in clamping technology and is one of the world market leaders. The family-owned company is an expert on automation on the machine table, because practical, economical and quickly implementable solutions help to markedly increase productivity.

Categories

Brands

No brands provided.

Address

Waiblinger Straße 116Fellbach

70734

DE

Gripper – The integrated solution as Low-Cost-Automation

With the grippers from AMF your machine tool turns night into day. For as soon as the workpieces have been set up once, the tool works around the clock. It does not matter how many different workpiece are involved here. The special thing about this solution is that it uses existing resources.

The gripper is unloaded from the tool magazine and loaded into the machine spindle in order to use workpieces from a magazine in a clamping fixture. In this way, existing shift models are supplemented easily by worker-free shifts. A huge prolongation of machine time with very low investment costs.

Marking and cleaning tools – Low costs and huge time-saving

The high economic efficiency of marking and cleaning products stems from the low procurement costs, long service life and high working speed.

The AMF Writer and AMF Marker ensure a high-quality text – the surface of the workpiece is not damaged but is even strengthened here. With the Cleaner products the machine practically cleans itself.

Hydraulic clamping technology – the ideal solution for every requirement

The principle of hydraulic clamping technology serves as the basis for an extensive range of this product line, which is being expanded continuously with innovations and highlights. Here, the systematic further development for different versions is carried out, which are aligned fully to practical needs and requirements.

The variety of the offering in hydraulic clamping technology as well as the quality of every single product is impressive and convincing.

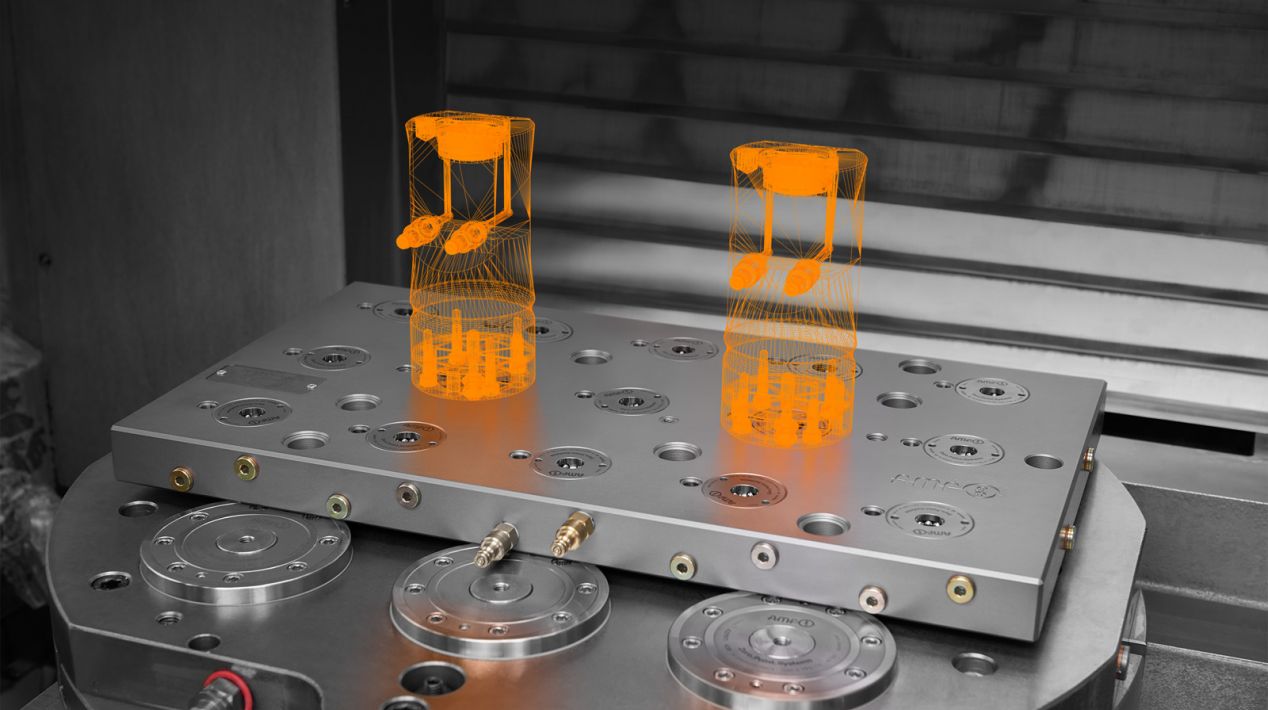

Zero-point-systems – The efficient zero-point clamping system

With technological superiority the zero-point system from AMF has virtually revolutionised the zero-point clamping technology market. The highly precise clamping modules with high draw-in, locking and holding forces ensure perfect clamping in the widest range of applications.

Extensive diversity and high repetition accuracy go without saying. The system demonstrates its strengths in daily production: optimised fixture and tool change ensure minimum set-up times and maximum efficiency.

Automation solutions with Zero-Point-Systems

Today, an automation solution consists of a number of networked, versatile products and technologies.

AMF's automation solutions meet the requirements for seamless integration into automation thanks to the possibility of fully automatic and reliable machine loading.

Numerous query options, optional media feed-through and blow-out and blow-off of the modules speak for themselves.

See the automation potential of our zero-point clamping modules for yourself!

SMART AUTOMATION

With SMART AUTOMATION, we offer a practical solution for automated workpiece handling on lathes and milling machines. SMART AUTOMATION can be operated without any programming knowledge. Production orders can be changed over quickly and flexibly, and the possibility of unmanned production during the night or at weekends becomes a reality. With SMART AUTOMATION, you significantly increase the productivity of your machine tool, while your skilled personnel are relieved of repetitive tasks so that you can utilise them more effectively.

Translated with DeepL.com (free version)

No brochures provided.

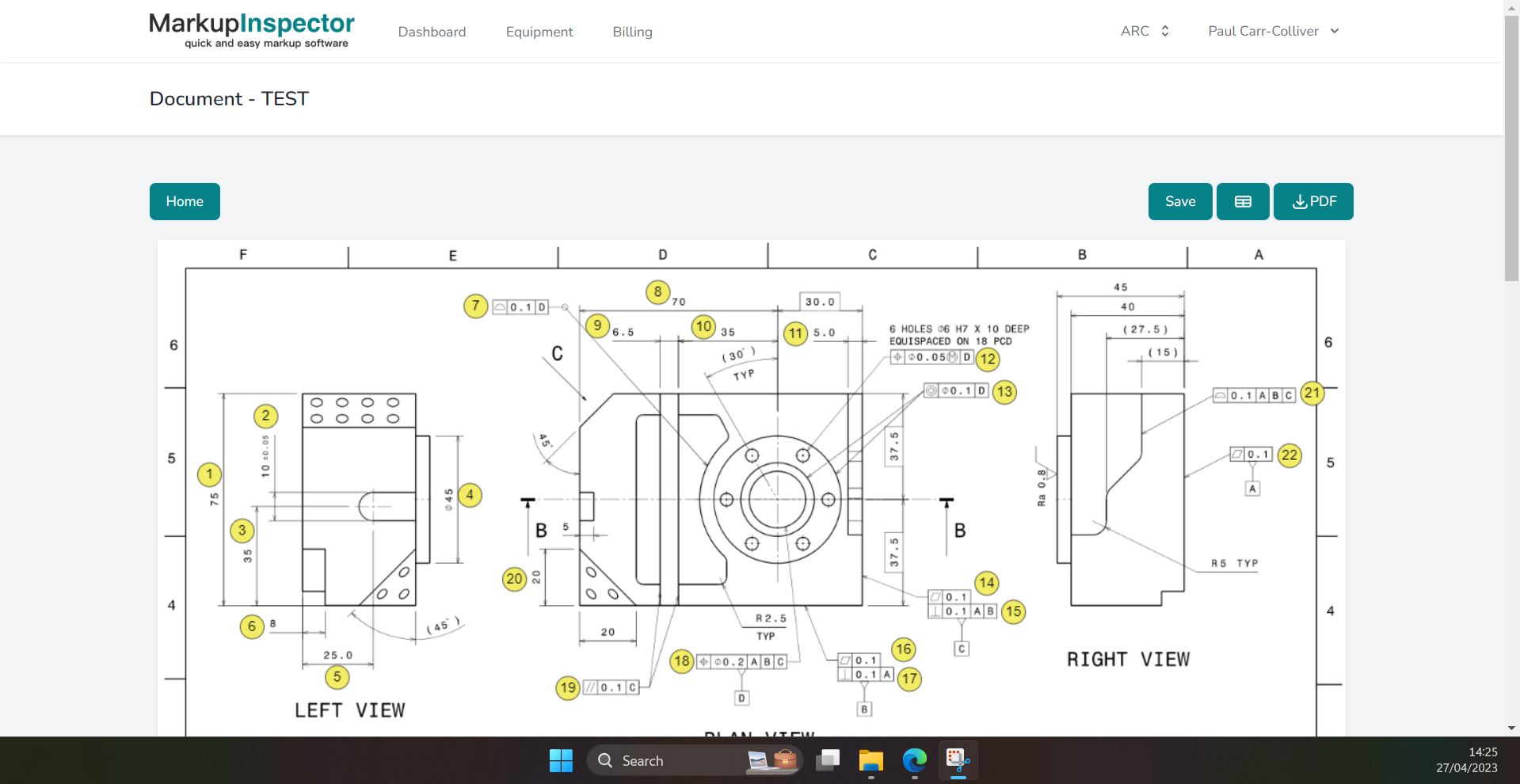

ARC METROLOGY

Stand: 19-740

ARC METROLOGY

Description

Arc Metrology Ltd., specializes in precise metrology services, software and product offerings. Leveraging a dedicated team, we deliver superior solutions, assisting businesses to boost quality through precise measurements. We're committed to accuracy, quality, and innovation. Reach out to us for bespoke metrology and products tailored to your needs

Categories

Brands

No brands provided.

Address

Cen2ury Business CentreDearne Lane

Manvers

Rotherham

South Yorkshire

S63 5DP

GB

CMM Verifications

The CMM Verification Artefact gives confidence in the accuracy of your CMM between annual calibrations by enabling you to independently verify your CMM accuracy. The Artefact includes UKAS certified calibrated length bars, ring gauge, ceramic sphere and is supplied with a one measurement program for in either Calypso, MCOSMOS, CAMIO, PC Dmis or MODUS

It is designed to be used between annual calibrations to highlight any issues with the machine's performance. An Artifact is designed to check singular or multiple axis to help you maintain the highest standards.

Includes

50mm Length Bar

300mm Length Bar

50mm Internal Ring Gauge

25mm Ceramic Sphere

UKAS Certificates

Carry Case

No videos provided.

ASH VISION

Stand: 19-746

ASH VISION

Description

ASH designs, manufactures, and distributes a unique range of high-definition digital and automated inspection solutions that are used in a wide range of industries. ASH systems make inspection processes smarter, and more efficient than using traditional inspection methods. Protect quality, minimise risk and meet demanding production requirements.

Categories

Brands

ASH

Address

Unit B5, M7 Business ParkNaas

Naas

Kildare

W91 P684

IE

Inspex 3

Powerful, flexible and intuitive HD digital microscope incorporating our new 30x HD Camera module. Ideal for industries such as medical device, pharma, precision engineering and electronics. Unique, patented, high-speed image processing algorithms for exceptional image quality. Super-fast focus speed and smooth digital zoom. Simpler, easier, more efficient inspection.

Omni 3

See what you need to see. Leverage advanced technology to move to hyper speed, super-precision, inspection. Omni 3 has been engineered to deliver one of the most advanced and intuitive digital microscope experiences. Powerful, embedded software can process complex imaging tasks without a PC. Custom designed to deliver maximum power.

Acumen AI

Acumen AI utilises next generation, deep learning video analysis and is designed and developed by Ash. Automatically identify, detect, classify, measure and count a wide range of part defects. Implementing the power of Acumen AI will significantly increase production efficiency, eliminate human error and increase production throughput.

Utilise the power of Acumen AI to develop your own machine learning models for your parts, for your needs.

Alternatively, tell us the problem and we can develop a complete Turnkey AI Solution.

ATA GARRYSON LTD

Stand: 18-730

ATA GARRYSON LTD

Description

ATA is a world-leading manufacturer and distributor of premium quality industrial and precision tools for companies needing a complete range of material removal, cutting, and finishing solutions.

The only precision engineering company in the world to supply both tools and consumables for a variety of deburring, material removal and finishing needs - across any material and any application.

Categories

Brands

ATA Garryson, ATA Karnasch

Address

Spring RoadIbstock

Leicestershire

LE67 6LR

United Kingdom

No products provided.

No videos provided.

AW PRECISION LTD

Stand: 20-30

AW PRECISION LTD

Description

When it comes to the precision engineering of punch and die products, we are pioneers in the field. Since our founding in 1970, our business has grown and evolved. We are now one of the leading manufacturers of punch and die products in the UK and Europe.

Categories

No categories provided.

Brands

Tecapres

GSB

Moeller

Address

64-66 Somers RoadRugby

Warwickshire

CV22 7DH

GB

Website

No products provided.

No videos provided.

No brochures provided.

AXE & STATUS MACHINERY LIMITED

Stand: 19-310

AXE & STATUS MACHINERY LIMITED

Description

Axe and Status, established in 1970 offer a range of machinery for both metal cutting and general fabrication.

We supply, install, maintain and offer comprehensive Service Support ongoing.

Categories

Brands

ACCURL fabrication machinery and fibre laser cutting machines,

Tuscan heavy-duty CNC oil country lathes,

Lazzati CNC Boring and milling,

Accuway CNC turning centres,

Eumach CNC vertical and horizontal milling machines,

Massa CNC vertical Turning lathes,

Millstar CNC vertical and horizontal milling machines,

Address

2, Holdom AveSaxon Park

Bletchley

Milton Keynes

Buckinghamshire

MK1 1QU

GB

No products provided.

MASSA-VLT-1600ATC+C

MASSA-VLT-1600ATC+C Axis series- Live Tools Functions Testing

ACCURL 20kw Laser Cutting Machine

ACCURL 20kw Laser Cutting Machine

ACCURL 5-axis Tube Laser

ACCURL 5-axis Tube Laser Cutter