3DPRINTUK

Stand: 17-516

3DPRINTUK

Description

3DPRINTUK are specialists in low volume manufacture using state of the art SLS and MJF 3D printing systems. Our aim is to bridge the void between prototype and injection moulding. If tooling costs are prohibitively expensive for your product or you don’t require the volume demanded by injection moulding, it’s time to reach out to our team.

Categories

No categories provided.

Address

Unit D9Leyton Industrial Village

Argall Avenue

London

Greater London

E10 7QP GB

No products provided.

No brochures provided.

DALTONS

Stand: 18-120

DALTONS

Description

Daltons, established in 1901, is a leading UK and Ireland supplier of industrial CNC machinery, specialising in high-performance solutions for multi-material processing. At MACH 2026, Daltons will showcase CNC routing, fibre laser cutting, 5-axis milling and press brake technology, supported by expert application knowledge and nationwide service.

Categories

Address

A L Dalton LtdCrossgate Drive

Queens Drive Industrial Estate

Nottingham

Nottinghamshire

NG2 1LW GB

Kimla BFP Linear CNC Router

The Kimla Industrial BPF CNC router takes all aspects of CNC machining to the next level. Processing speed, build quality, operating system and ease of use are unsurpassed. The multi-purpose capabilities of this CNC router make it suitable for almost any business working with wood, MDF, Plywood, aluminium and composites, cardboard, plastics and to name a few.

Houfek Maxx 8W

Designed for high production processing of metal punched/ laser-cut/ routed/ water-jet cut parts, the Houfek Maxx 8W offers both dry and wet configurations. Whether you are looking to calibrate, deburr, finish or edge round, this wide belt sander can be specified with any combination of roller disc and brush heads to deliver consistent, reliable results.

Kimla FineCut

Designed to cater for entry level production requirements, the Kimla FineCut is ideal for smaller companies looking to take their first step into fiber laser cutting. The FineCut has a compact footprint and a working area of 1000 x 2000 mm and up to 2 kW laser power and benefits from linear drives to each axis, automatic head height adjustment and anti-collision system as standard.

Kimla PowerCut

Truly awesome. The PowerCut delivers uncompromised performance maximising the synergy between fiber laser efficiency and Kimla’s unique CNC linear drive motion technology. With automatic pallet loading, compact operational footprint and a choice of laser powers up to 12 kW, the PowerCut is aimed at manufacturers looking for a reliable and efficient cutting system.

Kimla Fiber Lasers

DownloadABB ROBOTICS

Stand: 18-640

ABB ROBOTICS

Description

ABB Robotics is a pioneer in robotics, machine automation and digital services, providing innovative solutions for a diverse range of industries, from automotive to electronics to logistics. As one of the world’s leading robotics and machine automation suppliers, ABB Robotics employs more than 11,000 people in 53 countries and has shipped more than 500,000 robot solutions.

Categories

No categories provided.

Address

3100 Daresbury ParkDaresbury

WARRINGTON

Cheshire

WA4 4BT GB

No products provided.

No videos provided.

No brochures provided.

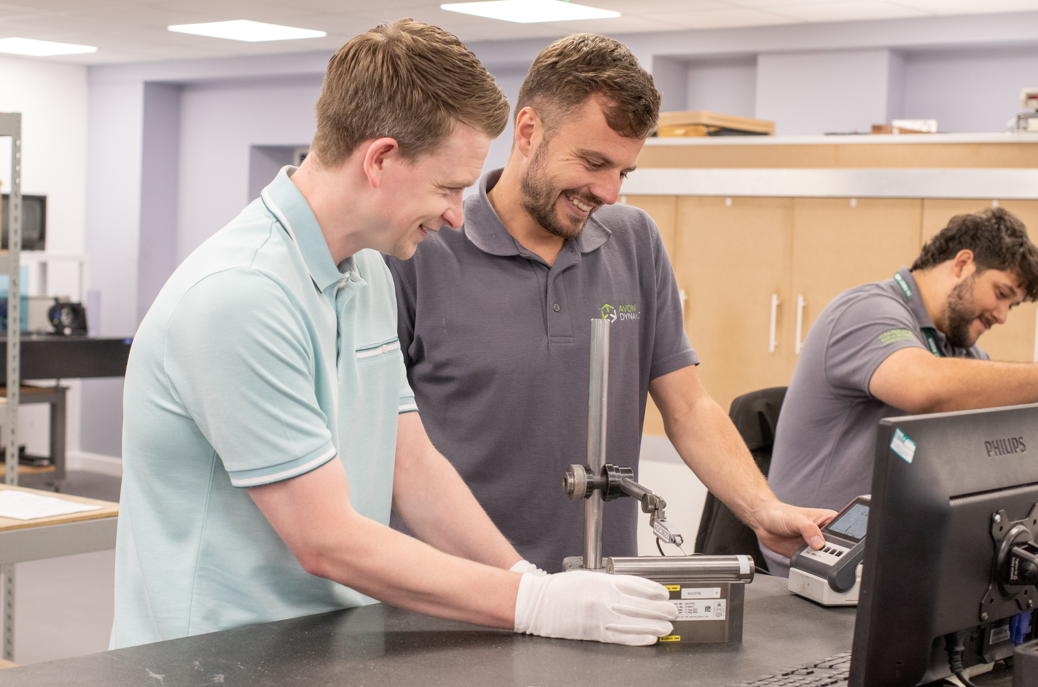

ABERLINK LIMITED

Stand: 19-738

ABERLINK LIMITED

Description

Since the launch of our first ground-breaking Coordinate Measuring Machine, the best-selling Axiom, Aberlink has earned a global reputation for producing a range of affordable CMMs and Optical Measuring Systems - recognised internationally for quality, accuracy, robustness, speed and ease of use.

Categories

Address

Aberlink Building Vatch LaneEastcombe

Stroud

Gloucestershire

GL6 7DY GB

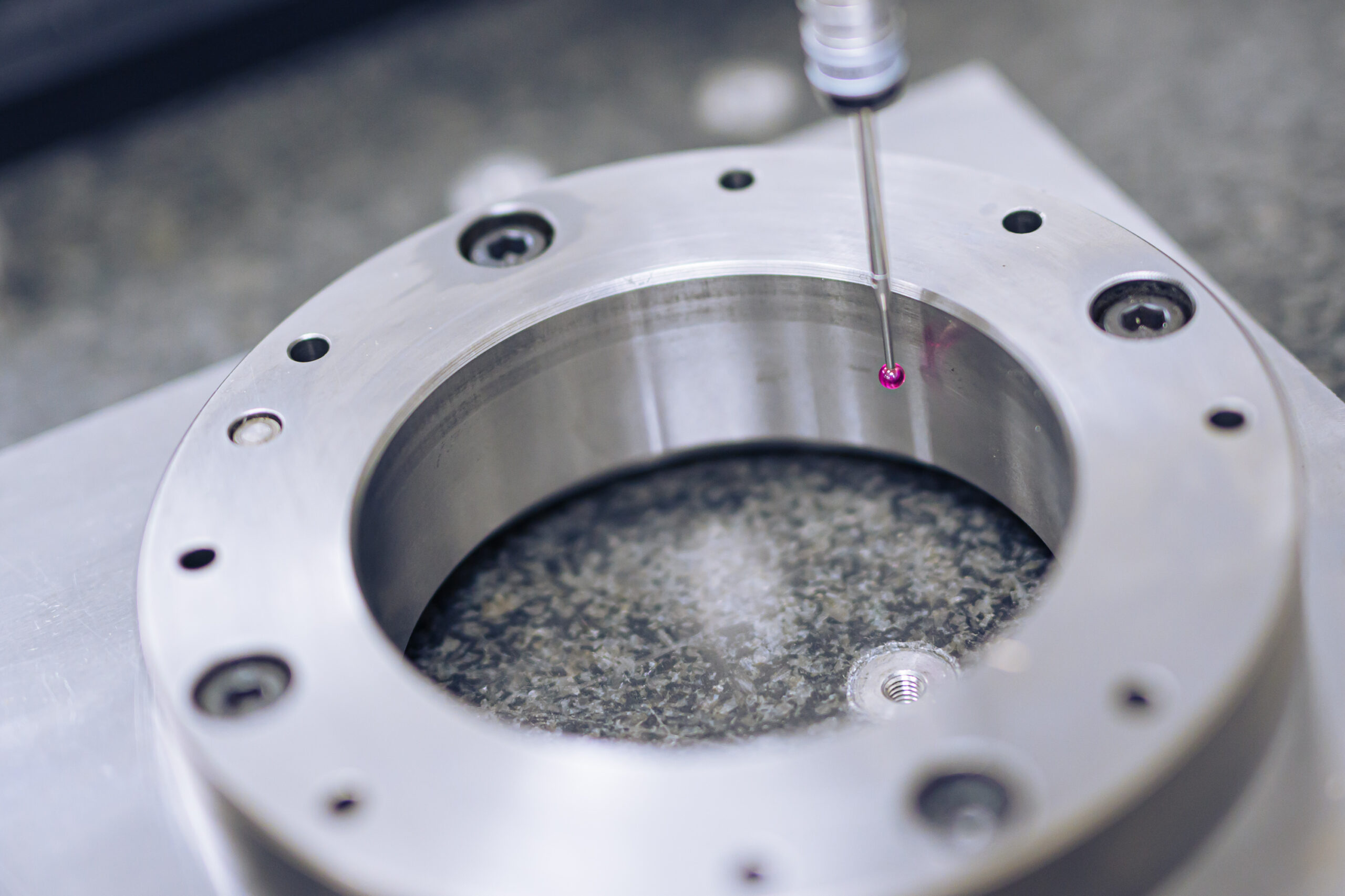

Axiom too CMM

The Complete Shop Floor Inspection System

Fast, accurate and reliable, the Axiom too CNC CMM comes in four different sizes with Y axis travel up to 1200mm. The Axiom too range of shop floor CMMs can be used with touch trigger probe, continuous contact scanning probe or with Aberlink’s revolutionary non-contact camera system.

The all aluminium bridge structure not only ensures that the Axiom too has low inertia and high acceleration to get the job done quickly, but also that the temperature of the machine rapidly follows the temperature of the room, ideal when the CMM is not housed in a controlled environment. Temperature compensation in the software reports results as if they had been measured at 20°C/68°F.

Horizon 1000 CNC CMM

Extending The Linear Drive Horizon

Drawing upon the tremendous success of the Horizon 800, the Horizon 1000 has a larger X-Y-Z axis travel whilst utilising the same frictionless linear drives.

The entire design of the Horizon 1000 has been optimised to take full advantage of parts already used on the Horizon 800 whilst improving the stiffness-to-weight ratio across the bridge assembly. Most notably: The Y-axis rail is 200mm taller so that the same right-hand-side linear drive system is common and improves rigidity; the carriage assembly has reduced in size and weight, without compromising metrology performance, to improve the stiffess-to-weight ratio; the Z-axis motor has increased power to optimise its performance; the left-hand-side air bearing assembly has a custom extruded profile to keep weight to an absolute minimum and maintain stiffness.

Extol CNC CMM

Next Generation Of Shop Floor Hardened, Non-Cartesian CMM

True to Aberlink's heritage for innovation, the Extol is the world's first CMM to utilise a delta mechanism.

Designed for robustness and reliability, the Extol CMM will run around the clock making it ideal whether it is positioned next to a machine tool, in a manufacturing cell, or used in a dedicated inspection area.

Five temperature sensors monitoring both the machine and ambient temperature ensure that the Extol is capable operating in uncontrolled environments and reporting measurements as though they had been taken at 20°C. The software will also produce a warning should the temperature change at a rate that is not conducive to reasonable metrology practice.

Robust, accurate, and reliable, the Extol CMM is the perfect solution to automatically verify part quality for critical components.

Fulcrum Manual CMM

Accurate Inspection Right Next To Your Machine Tool

Now supplied with a 3-year warranty!

Inspect your parts through every step of the manufacturing process.

The Fulcrum is a revolutionary manual CMM, by employing a three-rotary axis design, Aberlink has created a compact and portable design enabling it to be used where it is needed, on the shop floor near your machine tools.

Designed to optimize inspection as parts come off the machine one op at a time, feeding back to the machining process at the earliest opportunity, before final inspection, before more expense.

A simpler user interface has been developed for Aberlink measurement software, making it even easier to use on a manual CMM, while retaining full functionality. After manually scanning the part, critical features are automatically recognized, and dimensions are automatically displayed.

Intuitive software and innovative design mean you’ll be measuring your parts within minutes of switching on the Fulcrum CMM, even with no prior operating experience. It will quickly become the tool of choice for jump-on, ad-hoc inspection, whether checking 1st off inspection, small batch quality control, or setting CNC machines. The Fulcrum is the easiest CMM to learn and use.

Aberlink Product Catalogue

DownloadACCRETECH (EUROPE) GMBH

Stand: 18-519

ACCRETECH (EUROPE) GMBH

Description

ACCRETECH was founded in Tokyo in 1949 and is now one of the world’s leading providers of products for precision measuring equipment and of the most modern equipment for the semiconductor industry. ACCRETECH has been established on the European market since 1989 and now benefits from a comprehensive sales and service network.

Categories

Address

Landsberger Str. 396Munich

Bavaria

81241 DE

No products provided.

No videos provided.

No brochures provided.

ACCURIDE INTERNATIONAL LTD

Stand: 6-64

ACCURIDE INTERNATIONAL LTD

Description

Accuride is a global leader in engineered movement solutions for engineering and manufacturing professionals worldwide. We provide precision drawer runners and linear motion solutions for industrial use. With over 50 years of experience, our high-performance hardware supports robotic systems, automated material handling, equipment cabinets, and machinery.

Categories

Address

Liliput RoadBrackmills Industrial Estate

Northampton

Northamptonshire

NN4 7AS GB

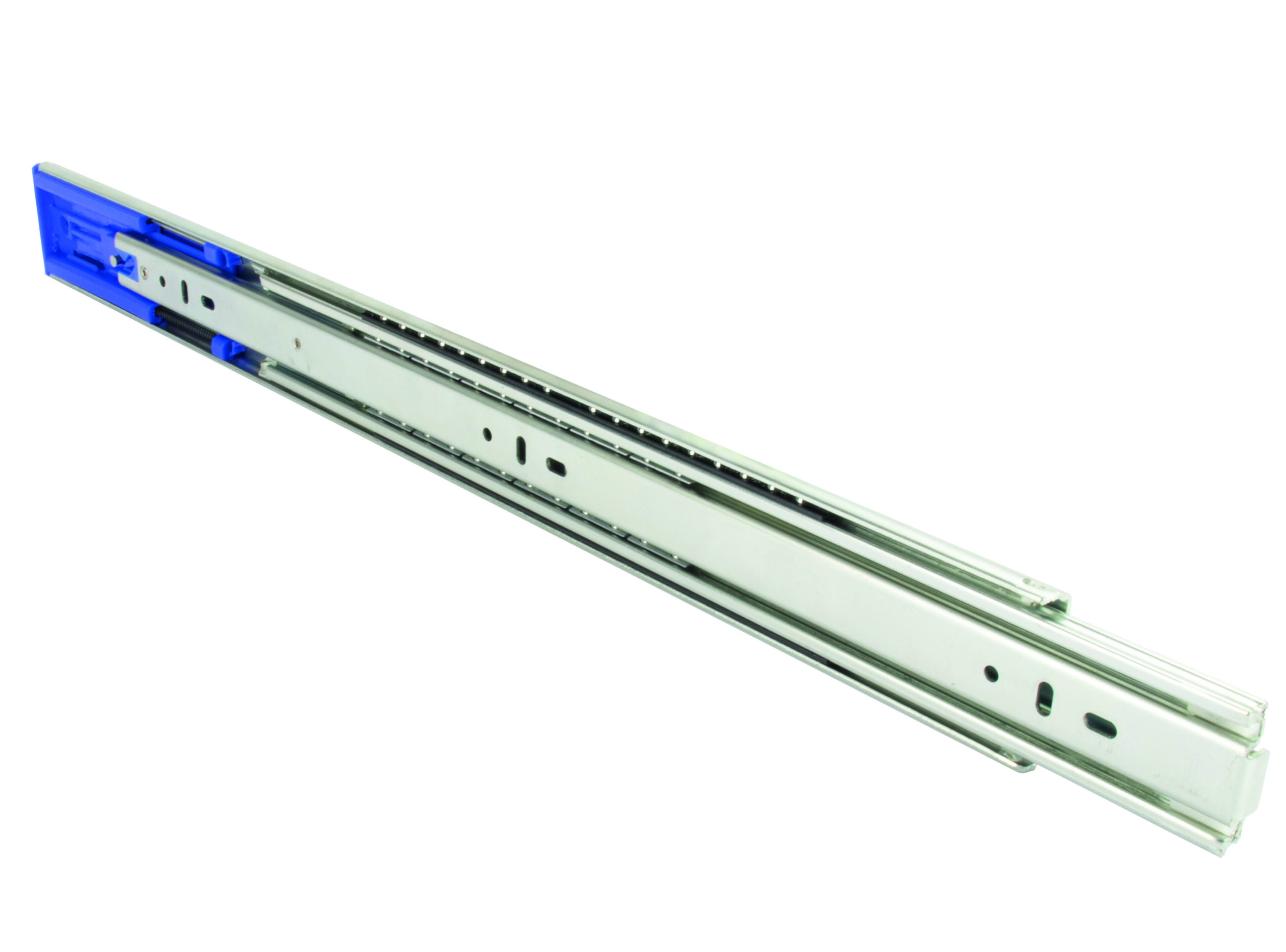

Light Duty Slide with Lock-In: DZ2731-CL

The DZ2731-CL is a light-duty, lock-in slide for environments that require secure positioning and space-efficient design. Featuring 100% extension capability, this compact slide offers full access for loads up to 30 kg, ideal for lighter storage and display applications. A front-mounted, dual-action lever allows intuitive unlocking in either direction, ensuring secure locking and quick access when needed.

With a low profile of 27 mm and a slide thickness of 19.1 mm, the DZ2731-CL fits seamlessly into slim cabinetry and shallow enclosures, optimising space without compromising strength or reliability. Its lock-in feature ensures drawers remain securely closed, beneficial for mobile or high-traffic retail environments.

The DZ2731-CL telescopic slide is equipped with a refined lock-in mechanism that enhances both security and usability. Designed for applications where maintaining a closed position is critical, i.e. mobile environments or high-traffic areas, this mechanism engages automatically when the slide is fully retracted.

A front-mounted lever release allows for smooth and intuitive unlocking, enabling quick access when needed. The dual-action lock-in lever can be pushed in either direction - up or down - to unlock the slide. This ensures reliable locking and easy unlocking at the same time.

Compact Design

Engineered with space efficiency in mind, the DZ2731-CL features a slim profile, measuring just 27 mm in height and 19.1 mm in thickness, ideal for integration into compact assemblies.

Full Extension for Accessibility

This slide offers 100% extension, allowing users complete access to the entire length of drawers or compartments. Full extension not only improves operational efficiency but also enhances safety and ergonomics by reducing the need to reach into confined or obstructed spaces.

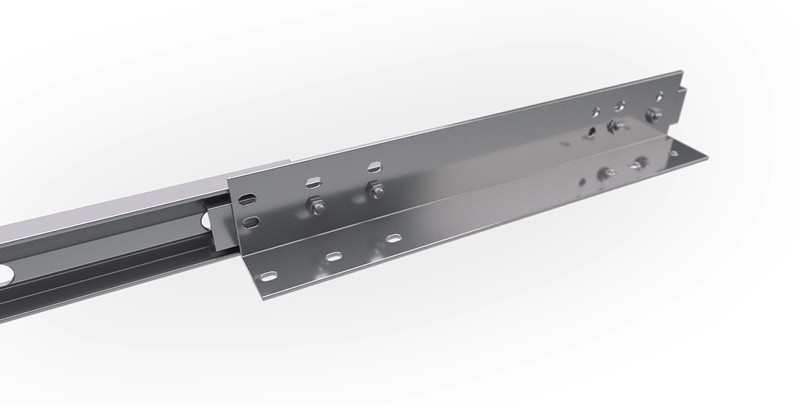

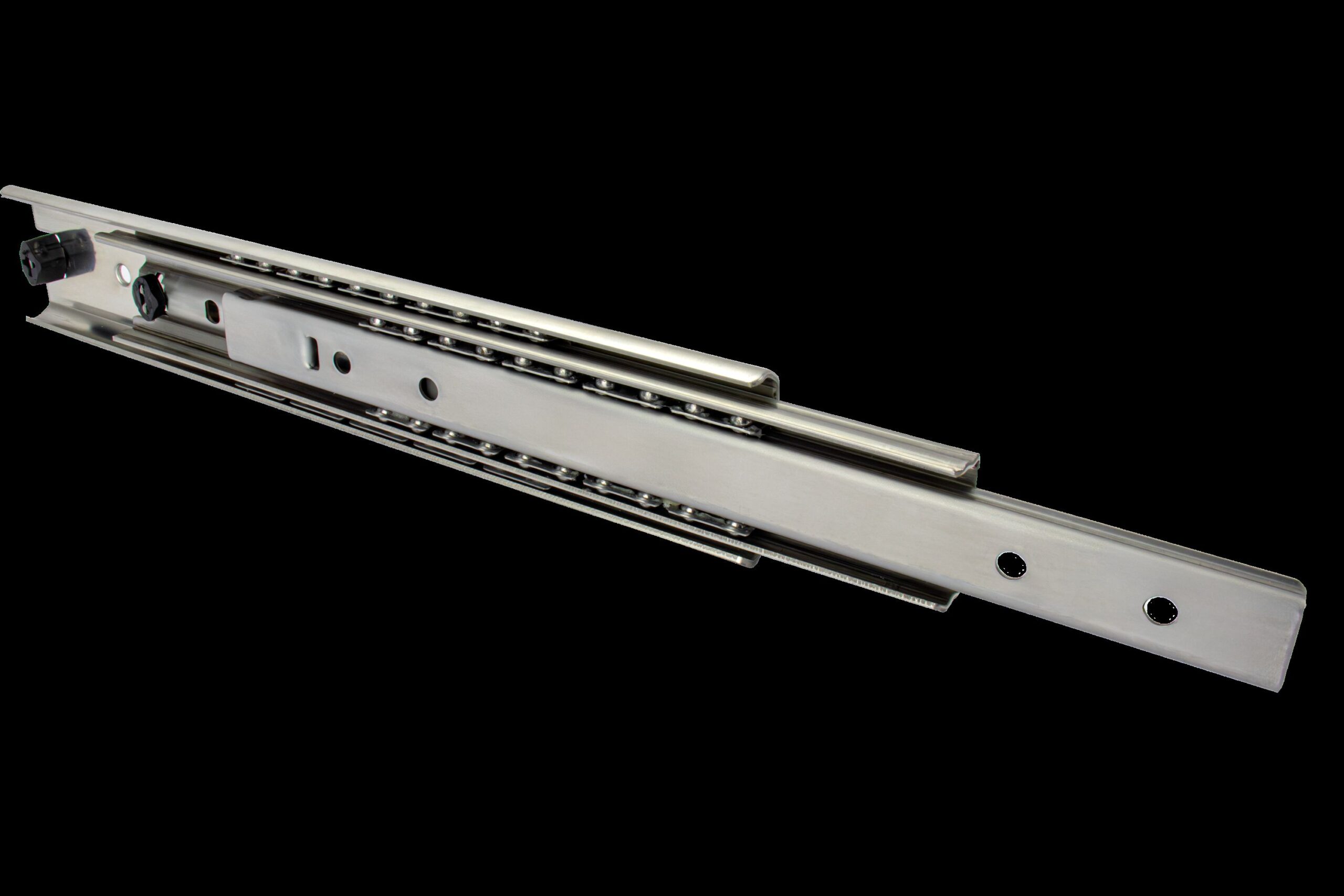

Heavy Duty Aluminium Two-Way Travel Slide DA4165-A

This heavy-duty two-way travel slide DA4165-A is made from corrosion resistant aluminium with a stainless-steel ball retainer and ball bearings, providing high-quality movement for even the most demanding applications. It offers solutions in industries including warehouse automation, railway, aerospace and marine.

Product Features:

Load rating up to 270kg

Two-way travel

26.5mm slide thickness

Stainless steel ball retainer and ball bearings

Corrosion resistant

Not suitable for flat mounting

Temperature -20°C to +70°C

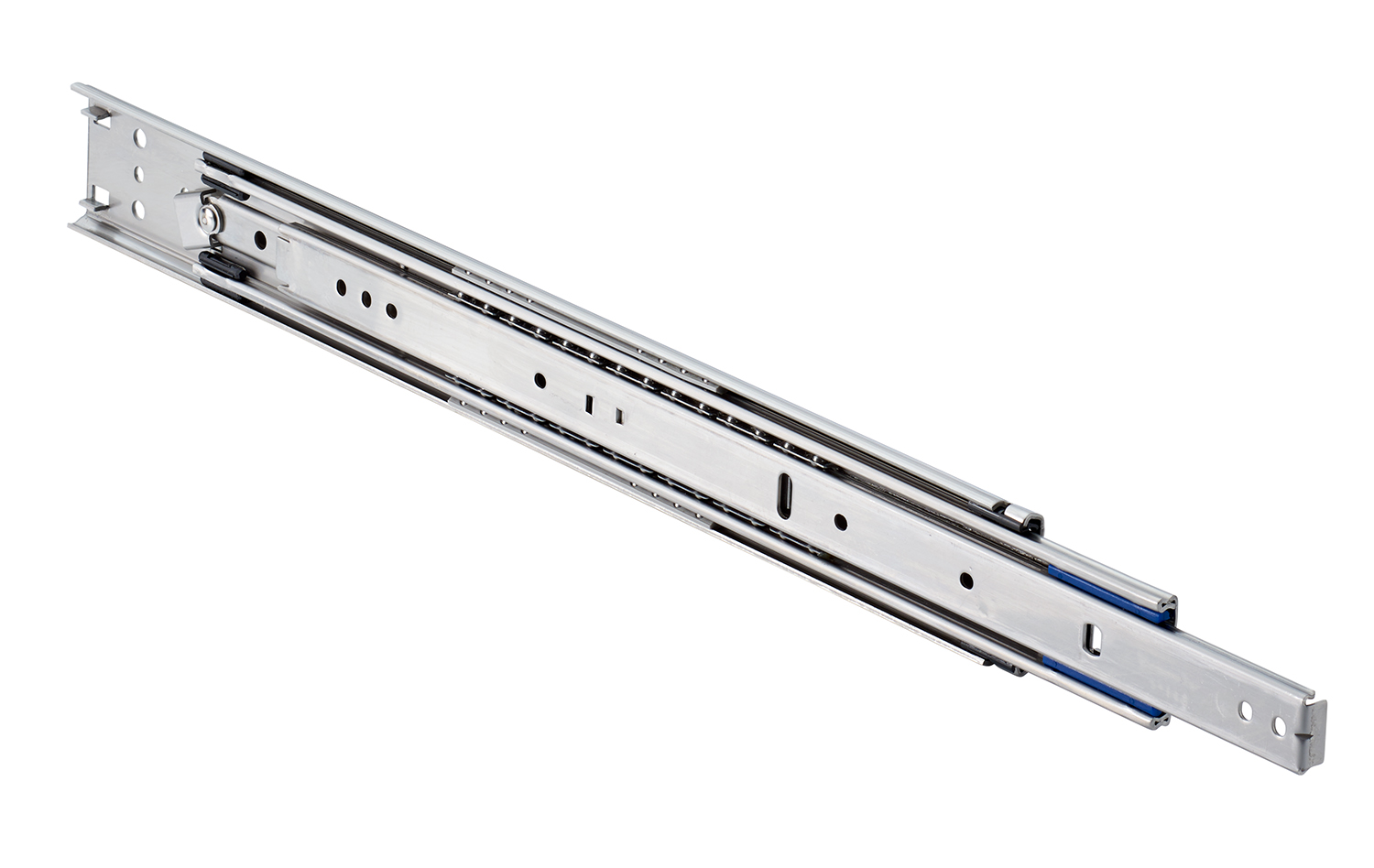

Heavy Duty Stainless Steel Telescopic Slide – DS5321

Our heavy duty stainless steel telescopic slide - DS5321 has a load rating up to 160-180kg with a hold-in feature. It's ideal for harsh environments where mild steel might be subject to corrosion.

The DS5321 stainless steel heavy-duty slide provides over 100% extension, corrosion resistance, and incredible strength, even at full extension.

Over-travel provides the added benefit of full, easy access to stored items, even those right at the back of the drawer. The DS5321’s hold-in detent prevents the drawer from rolling out or bouncing back during transit, providing reliable movement whenever it is needed.

Summary

- Load rating up to 160/180kg

- 100%+ extension

- 19.1mm slide thickness

- Ideal for environments where mild steel might be subject to corrosion

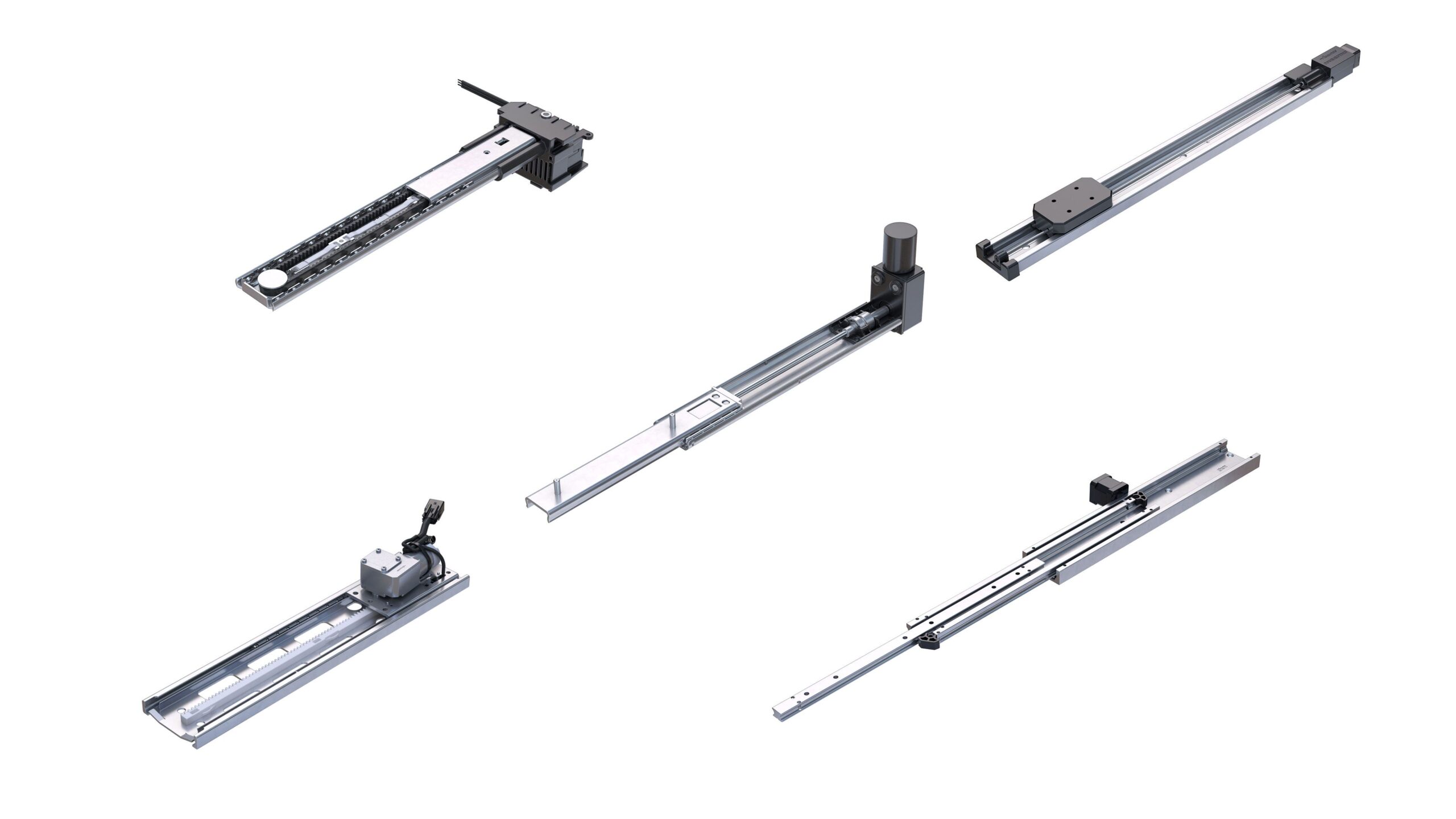

FULLELECTRIC® Motorised Slides for Robotics and Automated Systems: 3531 & 3532

At MACH 2026, we’ll be showcasing two slides from our FULLELECTRIC® family.

Automation is increasingly used in manufacturing and material handling, enabling tasks to be carried out quickly, efficiently, and with minimal human input.

The Accuride FULLELECTRIC® slide is designed to power these automated solutions. Driven by a compact yet powerful motor, it allows full integration into applications without compromising design or space.

Each slide can be customised to your requirements, making it suitable for a wide range of automated solutions, including:

- Robot delivery systems

- Automated factory storage and retrieval

- Industrial machines and equipment

- Unmanned production or logistics systems

- Automotive interiors and mobile equipment

Voice-controlled storage is available

You can pair the slide with a voice-assisted device opens up new possibilities within the home and for disabled access.

Visit us at Hall 6, Stand 64 to see live examples and discuss how FULLELECTRIC® slides can be integrated into your automation projects.

Marine Grade Stainless Steel Slide: DS3557

Marine grade 316 Stainless steel slide with lock-out and disconnect DS3557 with a load rating up to 90kg, medium duty with 100% extension, and 12.7mm slide thickness.

- Material and Finish: Marine-grade 316 stainless steel for superior corrosion resistance

- Load Rating: Up to 90 kg (medium duty)

- Extension and Thickness: 100% extension with 12.7 mm slide thickness

- Safety and Convenience: Pinch-free design with spring disconnect for easy and safe drawer removal and reinsertion

- Temperature Range: Operates reliably between -20 °C and 70 °C

- Applications: Suitable for refrigerators, freezers, and marine environments

Applications:

- Industrial and Manufacturing: Tool drawers, parts storage, and workstation cabinets with medium-duty loads

- Marine and Outdoor: Boats, offshore platforms, and harsh environments where corrosion resistance is critical

- Maintenance and Service Teams: Easily removable drawers for equipment access, servicing, and cleaning with pinch-free spring disconnect and lock-out

When They Are Used:

- In high-use, medium-duty industrial environments requiring smooth, reliable operation

- Where safety is important, preventing accidental drawer removal or finger pinches

- In corrosive or temperature-sensitive environments, including marine, outdoor, and industrial enclosures

Full Extension Slide with Touch Release: DZ4501-TR

DZ4501‑TR Full Extension Slide with Touch Release

The DZ4501‑TR Full Extension Slide is a light-duty sliding solution designed for efficient, reliable access in industrial and professional environments. Sold as a pair, it is constructed from mild steel with a bright zinc finish and has a load rating of up to 35 kg. Engineered for durability and ease of use, it provides 100% full extension, allowing unobstructed access to the back of the drawer.

Key Features:

- Touch-to-Release / Push-to-Open: Opens effortlessly with a simple touch, eliminating the need for handles

- Front Lever Disconnect: Simplifies installation and allows easy removal for maintenance or reconfiguration

- Hold-In Function: Keeps drawers securely closed for safety and stability.

- Breathing Tabs: Ensure precise alignment and a smooth, straightforward installation

Applications

- Mobile equipment and workstations, including tool trolleys and service carts

- Industrial displays for parts, samples, or lightweight components

- Maintenance and service environments where quick, reliable drawer access is required

When They Are Used:

- In light-duty industrial settings requiring smooth, effortless operation

- Where safety and precision are important to prevent misalignment or accidental drawer removal

Soft Close Drawer Side DZ3932-EC

The DZ3932-EC soft close medium duty slide provides a smooth and controlled closing action for delicate equipment and noise-sensitive environments.

This versatile slide can support weights of up to 68kg with a 100% extension and front disconnect.

The front disconnect feature makes the slide easier to install, and also means that the user can detach the slide during use if necessary, for example for maintenance.

- Medium duty slide

- Suitable for use with (or as a replacement for) the light duty 3832-EC-B soft close slide, due to similar slide cross-section

- Soft close feature (also called easy close) slows the closing action of the slide for a controlled, smooth slide closure

- 100% extension for easy and uninhibited access to the drawer contents

- Suitable for delicate objects and sounds-sensitive environments

- Front lever disconnect, for easy installation and maintenance

- Not suitable for flat mounting

Full Extension Heavy-Duty Telescopic Slide with Lock-In and Detent-Out: DZ5306-DO

Equipped with a hold-out feature to maintain an open position and a lever-operated Lock-In mechanism for secure closure, it offers enhanced safety and stability.

The DZ5306-DO Redefines Strength and Precision

Experience the perfect blend of strength and precision with the DZ5306-DO telescopic slide, a robust and versatile solution crafted for the most demanding industrial and heavy-duty applications. Engineered for smooth performance and long-lasting durability, this slide offers full-extension functionality, providing complete access to drawers and compartments. Its advanced design makes it ideal for environments where precision, strength, and stability are crucial.

Enhanced Safety with Dual Locking Features

This model is equipped with dual locking capabilities to enhance both safety and convenience. A hold-out feature keeps the slide securely open, maintaining a stable position during use to prevent unintended closure. Additionally, the lever-operated Lock-In mechanism holds the slide firmly shut when needed, providing stability during transport or heavy-duty operations. The intuitive lever design offers effortless control for reliable engagement and release.

High Load Capacity and Robust Performance

The DZ5306-DO slide is built to handle substantial loads, supporting up to 120kg per pair. This heavy-duty capacity ensures dependable strength for demanding applications. Designed to operate reliably across a wide temperature range from -30°C to 70°C, it performs consistently even in demanding environments.

Compact Dimensions and Durable Surface Finish

With a thickness of 19.1mm and a height of 53.1mm, the slide combines a compact profile with robust strength. With a length range of 300mm to 1100 mm, this slide provides versatile sizing to accommodate a range of applications. Constructed from high-quality mild steel with a bright zinc finish, it offers excellent protection against wear and rust.

Heavy Duty Telescopic Slide with Disconnect Easy Close: EDZ5334-EC

The Accuride DZ5334-EC is a high-performance telescopic slide designed to deliver a premium user experience in both commercial and residential drawer applications. Featuring integrated Easy-Close functionality, this slide ensures drawers close smoothly and silently, enhancing both convenience and durability.

With a load rating of up to 90 kg per pair and 100% extension, the DZ5334EC is ideal for wider drawers — up to 1,000 mm — and offers full access to stored contents. Its compact 19.1 mm slide thickness allows for easy installation in space-conscious environments, while the front disconnect feature simplifies maintenance and installation.

Reliability and Performance

The DZ5334-EC guarantees smooth and reliable movement. It has been validated to 80,000 cycles at rated load (depending on the slide length). Whether in commercial settings or residential spaces, rest assured that this slide can handle the demands of your storage requirements.

Typical applications include:

- Industrial tool storage and workstations – Suitable for tool chests, technician drawers, and mobile workstations requiring high load capacity and long service life.

- Manufacturing and workshop environments – Supports drawers and sliding trays in production, maintenance, and assembly areas where durability and misuse resistance are critical.

- Technical offices and engineering workspaces – Ideal for filing systems, under-desk storage, and sliding work surfaces in professional environments.

- Medical and laboratory equipment – Provides smooth, controlled motion for storage and access systems requiring precision, reliability, and repeatable performance.

- Equipment and system enclosures – Suitable for access drawers and trays within machinery and technical enclosures.

Easy Access with Full Extension:

The full extension feature allows the user to reach the back of drawers or compartments effortlessly, enhancing convenience and practicality in your storage solutions.

Soft Close Feature:

The DZ5334-EC is designed for a smooth user experience, featuring a soft-close mechanism for the last 45 mm of the closing cycle. Enjoy smooth and quiet closure, minimizing noise and preventing abrupt slamming.

The DZ5334-EC slide is one of the few slides with a soft close feature which can function in temperatures as low as 0°C, making this slide ideal for applications like refrigerated storage or cold rooms.

Front Disconnect Feature:

For added convenience, the front disconnect feature allows easy disconnection of the slide. This makes maintenance, cleaning, and installation of the drawer hassle-free, ensuring that your storage solutions remain efficient and user-friendly.

Wide Drawers:

The DZ5334-EC can accommodate wide drawers up to one meter wide with minimised racking. We recommend that a centrally positioned handle is used on wide drawers.

Telescopic Slide – 150%+ extension: DZ5351

The DZ5351 is a heavy-duty telescopic slide offering over-extension of 150%+, providing exceptional access to drawer contents. Rated to support loads of up to 100 kg, it is manufactured from robust zinc components for strength and durability. Designed for demanding industrial applications, the DZ5351 is suitable for large drawers, sliding trays, and equipment access where extended reach, stability, and reliable performance are required.

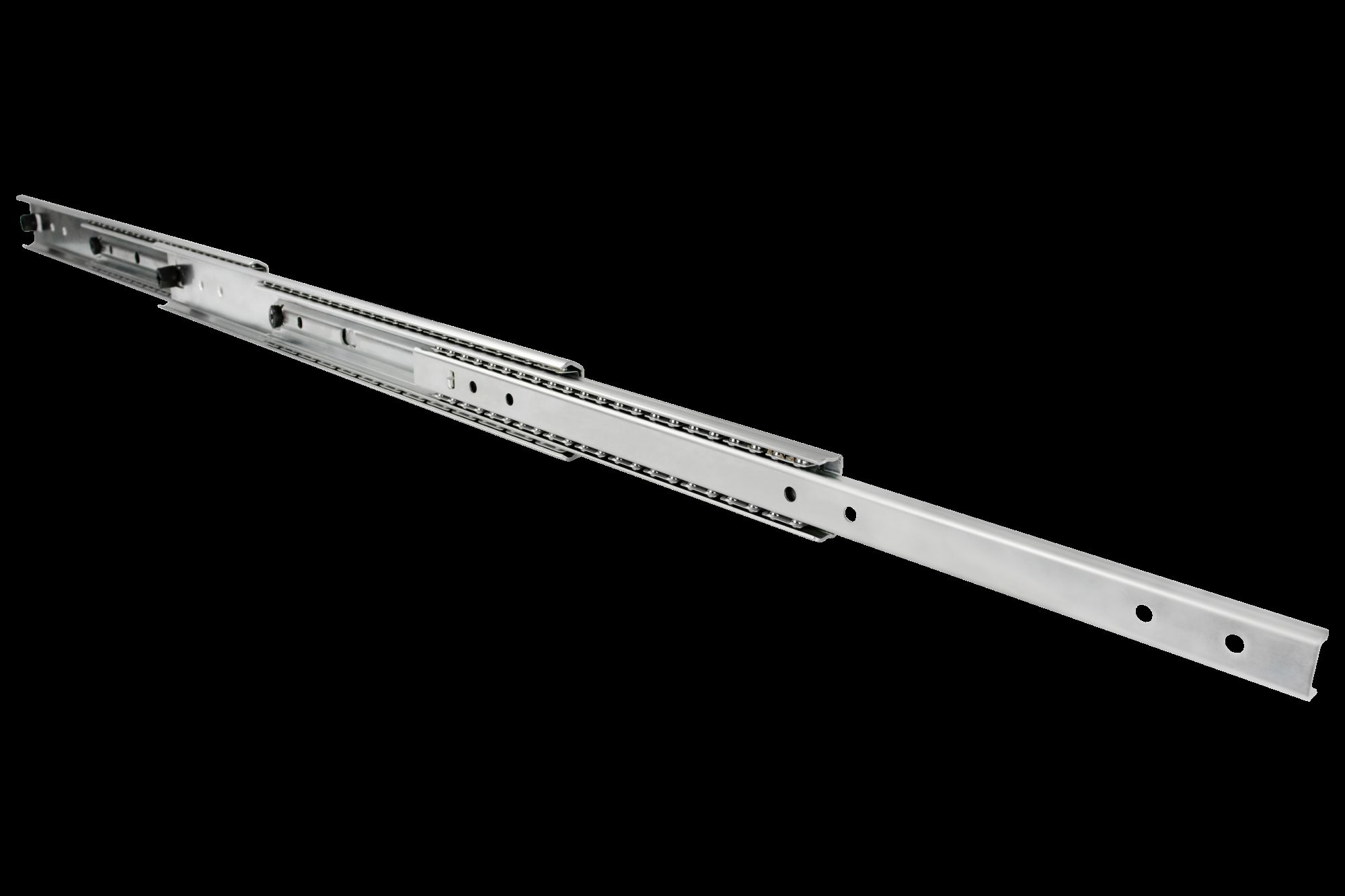

Heavy-Duty Interlock Telescopic Slides with Anti-Tilt and Hold-In (100 kg): DZ5343 + DZ5344

The DZ5343 is a heavy-duty anti-tilt drawer slide with an optional interlock, rated for up to 100 kg. It features full (100%) extension, 19.1 mm slide thickness, and is suitable for drawers up to 1000 mm wide. The interlock system ensures only one drawer can open at a time, enhancing operator safety and system longevity. The hold-in feature prevents undesired movement, allowing drawers to open only when force is applied.

The DZ5344-U is an optional companion slide for the DZ5343, also rated for 100 kg, heavy-duty, and with 100% extension. It includes the hold-in feature but does not contain an interlock, providing balanced support as part of the system. Together, the DZ5343 + DZ5344-U system delivers reliable, safe, and stable operation for heavy-duty drawers and equipment access in industrial, workshop, and OEM applications.

(Image used is the DZ5343)

NEW DON’T DELETE – Light Duty Slide with Lock-In: DZ2731-CL

The DZ2731-CL is a light-duty, lock-in slide for environments that require secure positioning and space-efficient design. Featuring 100% extension capability, this compact slide offers full access for loads up to 30 kg, ideal for lighter storage and display applications. A front-mounted, dual-action lever allows intuitive unlocking in either direction, ensuring secure locking and quick access when needed.

With a low profile of 27 mm and a slide thickness of 19.1 mm, the DZ2731-CL fits seamlessly into slim cabinetry and shallow enclosures, optimising space without compromising strength or reliability. Its lock-in feature ensures drawers remain securely closed, beneficial for mobile or high-traffic retail environments.

Applications

Lockable Shelves - Storage in mobile applications where the drawer must remain closed, e.g. trolleys, van storage, ambulances.

Mobile Merchandising Carts - Lock-in shelves that stay put while moving through aisles.

Medical equipment - 100% extension and a lock-in mechanism makes this slide ideal for use in hospital carts, equipment drawers, etc.

Lock-In Feature

The DZ2731-CL telescopic slide is equipped with a refined lock-in mechanism that enhances both security and usability. Designed for applications where maintaining a closed position is critical, i.e. mobile environments or high-traffic areas, this mechanism engages automatically when the slide is fully retracted.

A front-mounted lever release allows for smooth and intuitive unlocking, enabling quick access when needed. The dual-action lock-in lever can be pushed in either direction - up or down - to unlock the slide. This ensures reliable locking and easy unlocking at the same time.

Compact Design

Engineered with space efficiency in mind, the DZ2731-CL features a slim profile, measuring just 27 mm in height and 19.1 mm in thickness, ideal for integration into compact assemblies.

Full Extension for Accessibility

This slide offers 100% extension, allowing users complete access to the entire length of drawers or compartments. Full extension not only improves operational efficiency but also enhances safety and ergonomics by reducing the need to reach into confined or obstructed spaces.

NEW DON’T DELETE Heavy Duty Stainless Steel Telescopic Slide: DS5321

The video shows an example of the 5321 slide with a bracket.

About the Slide:

Our heavy duty stainless steel telescopic slide - DS5321 has a load rating up to 160-180kg with a hold-in feature. It's ideal for harsh environments where mild steel might be subject to corrosion.

The DS5321 stainless steel heavy-duty slide provides over 100% extension, corrosion resistance, and incredible strength, even at full extension.

Over-travel provides the added benefit of full, easy access to stored items, even those right at the back of the drawer. The DS5321’s hold-in detent prevents the drawer from rolling out or bouncing back during transit, providing reliable movement whenever it is needed.

Summary

- Load rating up to 160/180kg

- 100%+ extension

- 19.1mm slide thickness

- Ideal for environments where mild steel might be subject to corrosion

FULLELECTRIC Slides leaflet

Customisable for your Applications

Different FULLELECTRIC® slides, with variable design (full extension, part extension, linear slide, two way travel), drive technology (lead screw, belt drive, rack-and-pinion-drive) and motor technology (stepper motor, BLDC motor or DC motor) are available.

The made-to-order slide can be customised, making it suitable for a range of automated solutions, including robot delivery systems, factory storage, luxury furniture and car interiors.

DownloadACTON FINISHING LTD

Stand: 20-480

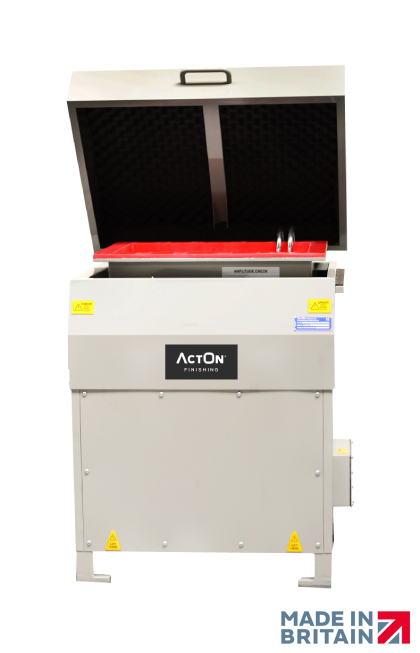

ACTON FINISHING LTD

Description

With a legacy dating back to 1965, ActOn Finishing has emerged as a prominent family business dedicated to delivering exceptional surface finishing products and services. Throughout our journey, we have focused on designing and manufacturing high-standard solutions for surface finishing, shot blasting, waste water treatment and ultrasonic cleaning.

Categories

Address

213 Torrington AvenueTile Hill

Coventry

West Midlands

CV4 9HN United Kingdom

Mass Finishing Consumables

We offer a range of Finishing Consumables to help our customers achieve the surface finish they need. We can cater to all your application requirements including deburring, degreasing & oil removal, cleaning, descaling, radiusing, smoothing and polishing. We will offer you full support every step of the way. Our range of consumables includes:

- Ceramic media

- Plastic media

- Agro and pre-treated media

- Shot blasting media

- Stainless steel polishing media and wood media

- Liquid finishing compound

- Powders, pastes & special compounds

- Consumables for water treatment

- Ultrasonic cleaning solutions

Wheel Blasting Machines

At ActOn we now offer a range of Wheel Blast Systems to help you achieve the surface finish you need. We can cater to all your application requirements including descaling, removal of corrosion or rust, paint stripping, de-flashing, achieving a smooth finish, shot peening, polishing and surface preparation prior to coating. We will offer you full support every step of the way.

Shot Blasting Cabinets

At ActOn Finishing we offer a wide range of shot blasting machines to help our customers achieve the surface finish they need every time. Whether you require to descale, remove corrosion, mill scale, paint or rust, achieve a smooth finish, deflash, polish or strengthen the metal we will offer you full support every step of the way.

Our range includes a Mobile Blasting Series; The ECO Blasting Series an economical range of Suction Blast,

Wet Blast and Pressure Blast machines; The Premium Blasting Series which consists of Suction Blast,

Wet Blast and Pressure Blast machines; the AM Blasting cabinets for finishing metal and polymer 3D printed parts; and Automated Blasting Machines.

Ultrasonic Cleaning Systems

ActOn Finishing Ultrasonic Cleaning Machine UK is designed to clean, descale and strip a large range of components. It's perfect for a range of industries such as automotive, aerospace, energy, electronics, food, graphics, jewellery, manufacturing, marine, mould cleaning, medical, optical and more. This technology includes a Standard Series, a Laboratory Series, the Ultrasonic Machines built for the Automotive Industry and Customised Ultrasonic Systems.

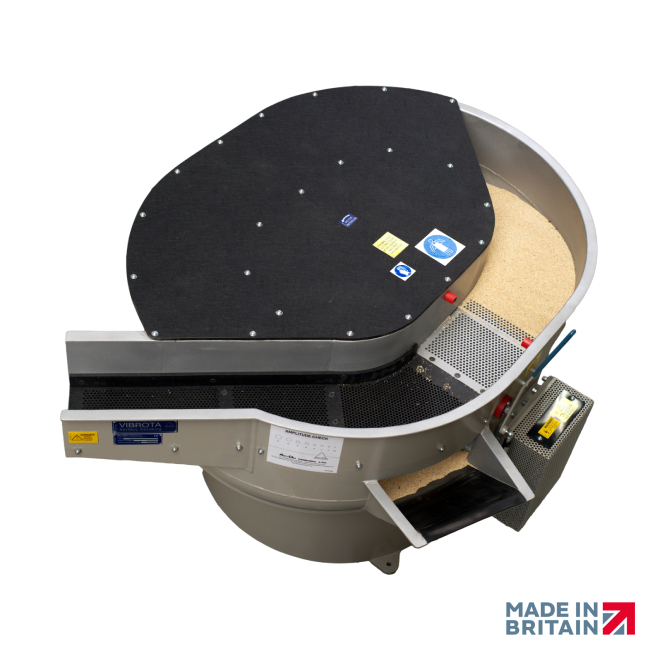

Centrifugal Disc Machine

ActOn’s Centrifugal Disc finishing machines have been designed to be reliable and easy to operate. These machines are perfect for processing small and thin components as well as larger parts with a length of 150mm.

The Centrifugal Disc Finishing Machines are recommended for processing small to medium batches of parts. The spinning motion of the disc machine is given by the disc situated at the bottom of an open barrel. The rotating disc makes the media, compound and parts to move in a rolling motion, resulting in a effective finishing process in the shortest time.

Centrifugal High Energy Finishing Machine

ActOn’s Centrifugal High Energy Finishing machines are possibly the most efficient of the finishing systems available in the industry. These machines generate a very high gravitational force and are designed to maximise the output.

In many cases, the results achieved via CHE Finishing cannot be achieved in a standard vibratory process. Particularly applications that include achieving a high surface finish requirement, a mirror finish and the removal of heavy manufacturing defects. Parts that require hand finishing are excellent candidates for High Energy Finishing. These machines can be 10 times faster than vibratory finishing, producing superior finishes.

Mass Finishing Machines

ActOn range of mass finishing machines includes: Vibratory Finishing Bowls, Troughs, Duals and Dryers; Rotary Barrel Machine; Vibratory Wheel Polishing Machines, Automated Systems and the DLyte Electropolishing Systems.

Using quality mass finishing vibratory machinery, media and compounds, we indulge in process development that is unparalleled. Our engineers have worked tirelessly over the years to provide you with quality and cost-effective finishing solutions. The developments have been in all areas, from the Vibratory and High Energy finishing technology to mass finishing consumables, to optimise in accordance to your needs.

Portable Shot Blasting Cabinets

Our Mobile Blasting Series includes 3 models: Powertrack Junior,Powertrack and a Mobile Blast Room. These blasting machines willoffer the perfect balance between productivity and portability. Some of the main advantages of the Mobile Blasting Series include:

- Are designed for a wide range of applications, including metal and stone finishing.

- Very economical and easy to operate.

- Easy to move.

Automated Mass Finishing Systems

Automated mass finishing technology reduces manual handling and ensures a consistent process. Our automated systems are operator friendly, and can be custom built to suit your needs. At ActOn Finishing we can design and manufacture Vibratory, Centrifugal High Energy, Centrifugal Disc automated finishing and Ultrasonic Cleaning systems.

LE30 Rotary Tumbling Barrel Machine

LE30 Rotary Tumbling Barrel Machine has been designed as an economic yet efficient finishing machine, for applications such as deburring, cleaning, descaling, polishing, removal of rust or smooth finishing. During the batch finishing process the barrel rotates the mix of media, compound, water and parts. The rotation of the barrel causes this mix to tumble down upon itself causing friction and thereby abrading the parts in the mass. Media and components loading and unloading is done manually.

Vibratory Wheel Polishing Machine

Designed to finish automotive wheels and motor bike wheels with sizes up to 610mm, the vibratory wheel polishing machine is great for grinding, smoothing and polishing processes.

At ActOn Finishing we have developed, in partnership with major manufacturers in the automotive industry, a high quality, repeatable finishing solution to achieve a highly polished finish in just a few hours. Our technical representatives can guide you to find the right media and compound to process your wheels and to achieve the mirror finish in the vibratory wheel polishing machine.

Mass Finishing Dryers

From classic size to bespoke specifications, our unique mass finishing dryers provide solutions for every one of your drying requirements. Hence you can choose between a Conveyorised Electrically Heated Drying Oven, a Vibratory Finishing Dryer, a Rotary Dryer, or a Centrifugal Dryer. When there is a space restriction and you need to dry small and medium sized components consider using a smaller finishing dryer such as ActOn's HD3000 or HT2D dryer.

Dual Surface Finishing Machine

This space-saving machine complements ActOn Finishing’s range of vibratory surface finishing systems. The design of the Dual Surface Finishing machine integrates two process chambers: an inner chamber that can be used for wet process application, and the outer chamber for dry process applications, both of which make it easier to control.

Vibratory Finishing Trughs

We offer Vibratory Tumblers and Finishing Troughs in many different sizes and an infinite choice of length and width combinations, making them one of our most versatile ranges of vibro machines. These Vibratory Tumblers are perfect for mass finishing larger, longer and irregular-shaped components.

Vibratory Finishing Bowls

Each of our vibratory bowl machines are simple to operate and highly efficient. These finishing machines have been manufactured in classic designs and sizes to meet a wide range of applications such as a vibration bowl polisher, deburring, descaling, radiusing, cleaning, polishing, burnishing and surface improvement.

Which mass finishing media is best to use in a finishing process?

Not sure where to start when it comes to choosing the right mass finishing media for your finishing process? That’s where we can help, join us as we explore the essential factors to consider when selecting the best media for your specific needs in our video.

ActOn Dry & Wet Shot Blasting Cabinets

At ActOn Finishing we offer a wide range of dry and wet shot blasting machines to help our customers achieve the surface finish they need every time. Whether you require to descale, remove corrosion, mill scale, paint or rust, achieve a smooth finish, deflash, polish or strengthen the metal we will offer you full support every step of the way.

ActOn ABC01 Batch Centrifuge – Waste Water Treatment Solutions

ActOn ABC01 Batch Centrifuge is designed to work in the most effective manner to treat the waste water from mass finishing, either suitable for recycling or discharge to the foul drain as dictated by the process.

The solids are captured in the basket of the centrifuge and then disposed of based on country specific regulations.

Vibratory Finishing Bowls vs Vibratory Troughs: Which one should you use for processing parts?

While vibratory finishing bowls can finish high volumes of parts per batch, vibratory troughs are ideal for large, long or irregular shaped components that cannot fit through the bowl's chamber.

Want to better understand the differences between vibratory bowls and vibratory troughs, their benefits and features? Join us as we discuss all of this to help you decide which one your business should use for processing parts in our video.

CHEF Machines vs Conventional Finishing Technology – Learn How to Achieve a Finish 10 Times Faster

ActOn’s CHEF (Centrifugal High Energy Finishing) machines are possibly the most efficient of the finishing systems available in the industry. In many cases, the results achieved via CHE Finishing cannot be achieved in a standard finishing process. Particularly applications that include achieving a high surface finish requirement, a mirror finish and the removal of heavy manufacturing defects. These machines can be 10 times faster than vibratory finishing, producing superior finishes.

Join us as we discuss the benefits of CHEF technology and more in our video.

Special EFX Testimonial – Pressure Blast Cabinet Improves Sand Blasting Process Time & Part Finish

At ActOn Finishing we offer a wide range of dry and wet shot blasting machines to help our customers achieve the surface finish they need every time. Whether you require to descale, remove corrosion, mill scale, paint or rust, achieve a smooth finish, deflash, polish or strengthen the metal we will offer you full support every step of the way.

ActOn Finishing – We Redefine Surface Finishing Solutions

Established in 1965 as a UK leading family business, at ActOn Finishing we’ve worked hard to design, develop and manufacture a product of high standard. We offer a complete end to end solution for mass finishing, shot blasting and waste water treatment. Some of the industries we cater include Aerospace, Additive Manufacturing, Automotive, Coin Blanking, Fashion, General Engineering, Hospitality and Medical.

Using our quality products, we can achieve a range of finishing applications which include deburring, descaling, degreasing, cleaning, smoothening, radiusing, brightening, polishing, drying, corrosion protection, mirror finish, surface finish, defect removal, stock removal, paint and coating removal, peening, weld splatter removal and much more.

ADDITIVE X

Stand: 17-520

ADDITIVE X

Description

Additive-X are Additive experts! We provide companies with unbiased advice about where to start, how to grow and innovate with 3D printing as well as maximizing commercial returns.

Product Profile: 3D Metal Printing, 3D Print Bureau, 3D Printing/Printers, SLA and CFR and FFF 3D Printing, SLS 3D Printing.

Categories

Address

The College Business ParkKearsley Road

Ripon

North Yorkshire

HG4 2RN United Kingdom

Markforged Mark Two

Introducing The Mark Two.

The Mark Two is a 3D printer for serious engineering and manufacturing applications. This is the first 3D printer in the world capable of printing composite materials with a heat deflection temperature of 140°C. So in addition to being able to reinforce nylon parts with continuous strands of carbon fibre, Kevlar and regular fibreglass, you can now reinforce parts with high-temperature materials like polycarbonate.

The Mark Two offers limitless possibilities.

Whether you are an engineer operating in aerospace, aviation, automotive, biotechnology, construction, marine or transport, or a manufacturer producing high-strength end-use parts and prototypes, the Mark Two is the 3D printer you’ve been waiting for. Parts that are reinforced with composite are as strong as 6061 aluminium and the Mark Two can reinforce features 15x smaller than the Mark One, boosting its applications considerably.

Markforged X7

Introducing the Markforged X7 - the most powerful composite 3D printer on the market. This 3D printer offers uncompromised strength and precision, with industrial-grade mechatronics and breakthrough technologies which transcend those on the market today.

Print with Markforged's full range of Composite Base materials and Continuous Fibers.

The X7 can print with Nylon or Onyx (ESD/FR) as the core build material, and can reinforce parts with Carbon Fiber, Fiberglass, Kevlar, High Strength and High Temperature Fiberglass and Precise PLA. Parts that are reinforced with a composite can be as strong as 6061 aluminum.

Print Enormous and Hugely Detailed Parts

The large build volume of the X7 makes it ideal for creating large-scale parts that currently only metal machining processes can handle. With the ability to print parts up to 330mm in width, 250mm in depth and 200mm in height, the X7 offers designers and engineers are real-world alternative to traditional manufacturing techniques. And with a 50-micron print resolution, your parts will come out with a beautiful finish, perfectly capturing the contours, details and textures you design or scan for print.

Markforged FX20™

The Markforged FX20 is the biggest, fastest, and most sophisticated 3D printer Markforged have ever built. It brings the Digital Forge and Continuous Fibre Reinforcement to a new realm of parts, problems, and industries.

Massive Builds, Faster

The FX20 pairs size and throughput to make larger builds at incredible speeds, delivering the transformational benefits of The Digital Forge at a new scale. At 4.7 times larger than the Markforged Industrial Series and three nozzles (two plastic, one fibre) you can see why it's been nicknamed 'The Beast'!

It features an 84L heated build chamber and massive, verified-flat vacuum bed with print sheets.

The motion control system offers closed loop control through precision linear encoders, and is tuned to move the 3kg print head rapidly and accurately.

FX20’s turbo mode builds parts faster than any Markforged machine, while new XL spools offer four times the material without spool changeover.

Markforged Metal X

The Metal X System is the most accessible way to fabricate complex metal parts in the widest variety of advanced metals.

From the company that revolutionised carbon fibre, Kevlar and fibreglass 3D printing comes a new breakthrough in metal 3D printing. The Metal X is a metal 3D printer that utilises a process called Metal FFF to print parts. This process uses metal powder and bulk sintering to create true-to-design solid metal parts, that can be made from a wide range of metals including Copper and 17-4 stainless steel.

The Metal X - The Ultimate Metal 3D Printer

The Metal X has a build volume of 300 mm x 220 mm x 180 mm (WDH) with an enclosed build chamber. It can print down to a layer height of 50-microns, and the user can make use of honeycomb infills and other geometries which would be impossible with subtractive and traditional manufacturing processes.

Metal FFF

3D printing metal parts has never been simpler than with the Metal X. Metal FFF prints your part using a bound metal powder surrounded by plastic. The plastic is then dissolved, and the metal powder sintered. The resulting parts are solid metal, with the same strength and durability as metal parts that have been cast.

The Metal X can 3D print several metals, including: 17-4 Stainless Steel, H-13 Tool Steel, 6061 Aluminum (Beta), 7075 Aluminum (Beta), A-2 Tool Steel (Beta), D-2 Tool Steel (Beta), Copper, IN Alloy (Inconel) 625 (Beta) and Titanium Ti-6Al-4V (Beta). The metals with beta next to them are currently in the last stages of testing, and will be approved for customers soon.

AMT PostPro DP PRO

The AMT PostPro DP PRO is the solution for cleaning or shot blasting parts hour after hour, eliminating time and cost-consuming interventions in your post-processing chain. It is ergonomically designed and equipped with features to increase your throughput.

Cleaning millions of parts

The generously sized basket, allows for optimization of the blasting angle, cleaning parts fast, while also allowing to easily switch between batches. Once you have found the ideal recipe for blasting your parts, you can store the settings, and reuse them again and again.

Large parts, small parts

PostPro DP PRO has a dedicated manual blasting area that allows fast blasting of large parts without changing anything in your automated blasting area. Again, nothing should stop you from successfully cleaning your parts.

User-friendly

PostPro DP PRO is designed with the operator in mind. It allows for a safe, sustainable and efficient user experience. It will prepare you for the next step in the post-processing chain.

DESIGNED SPECIFICALLY FOR ADDITIVE MANUFACTURING INDUSTRY

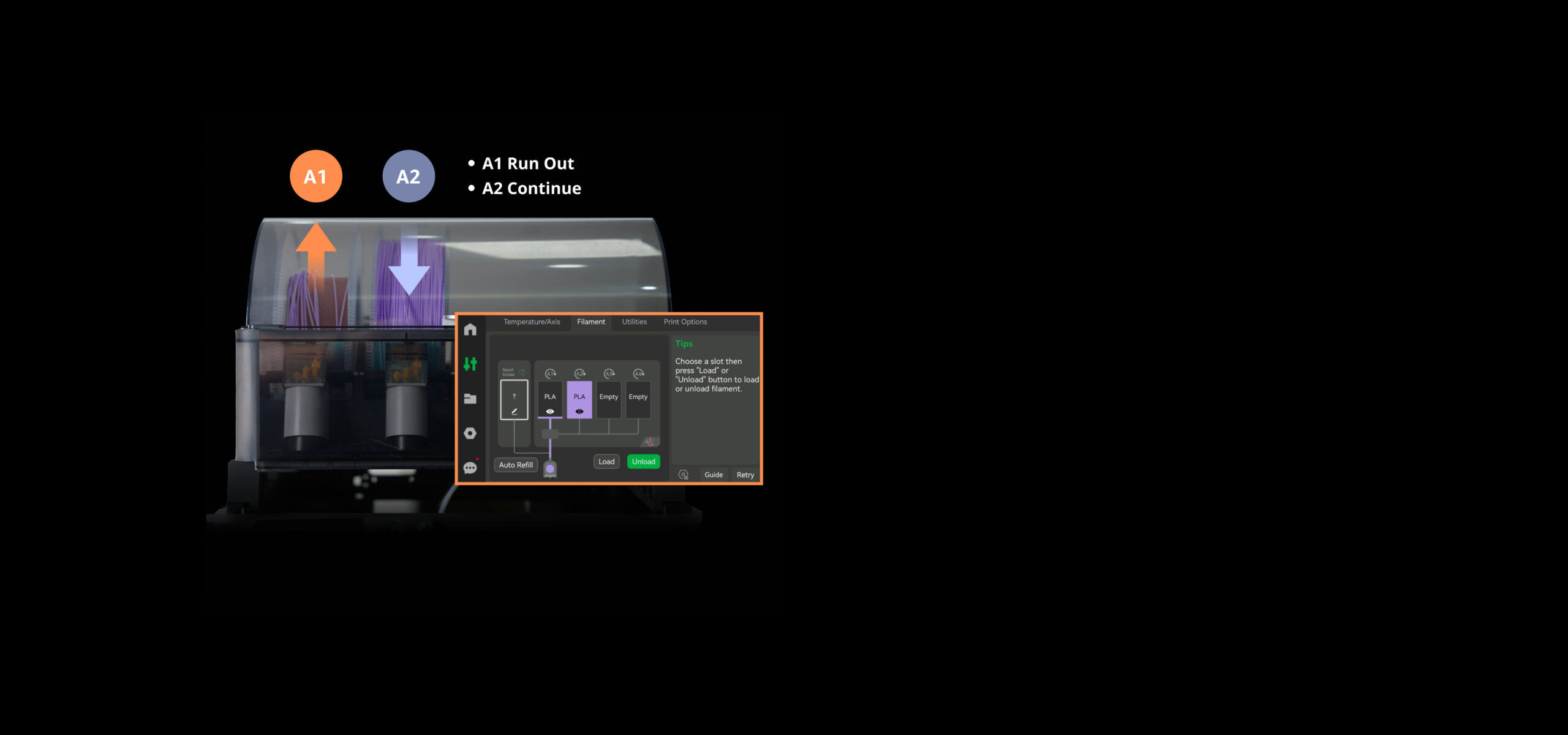

UltiMaker S7 Pro Bundle

The UltiMaker S7 Pro Bundle adds the Material Station to our newest S series 3D printer, transforming it into a manufacturing powerhouse. This one-of-a-kind upgrade further simplifies the 3D printing worklow with automatic switching of up to 6 spools. And constant humidity control ensures material is delivered in perfect condition for high-quality 3D prints.

Key Features

The Material Station enables the UltiMaker S7 to deliver 3D printed parts at maximum output. It does this by increasing uptime and minimizing the time operators need to spend at the printer.

The Material Station allows the S7 to print longer and been designed and tested to be left unattended

The UltiMaker S7 Pro Bundle optimizes the delivery of 3D printing materials so you don't have to. Perfect humidity control, reliable filament switching, and end-of-filament detection avoid human error and increase print quality.

The Material Station integrates with the UltiMaker S7, Cura, and the Digital Factory. It's never been easier to load and print with almost any combination of polymers and abrasive composites to unlock more 3D printing applications.

3DGence Industry F421

The 3DGence INDUSTRY F421 is a dual extruder FDM (fused deposition modelling) 3D printer designed for industrial applications where accuracy, speed, comfort and safety of the entire 3D printing process are crucial. This 3D printer is suitable for working with a wide range of technical materials including the high-performance thermoplastics and composites.

High speed

The 3DGence INDUSTRY F421 pushes the boundaries of the printing speed of industrial 3D printers.

The printing speed is the key aspect of the process, print speed up to 400 mm/s and 1 meter per second of travel move makes INDUSTRY F421 a great tool. It’s a great machine for rapid prototyping but also a full-fledged additive manufacturing system for your business.

Formlabs Form 3L Basic Package

The Form 3L is 5x larger than the Form 3, but with the same technology so you get all of the Form 3's reliability and consistency for much bigger prints. Two Light Processing Units (LPU) work simultaneously to produce large, dense parts fast.

Built around the same Low Force Stereolithography (LFS) process as the Form 3, the Form 3L produces industrial quality parts fast whilst retaining the ease of use and versatility that Formlabs is well known for.

No specialized technicians required. The Form 3L offers automatic resin dispensing, simple print preparation software, and a thoughtfully designed interface.

High-resolution touchscreen interface:

A 5.5” interactive full-color display minimizes error and eliminates the need for constant monitoring.

Automated print setup:

Tested over millions of prints, free print preparation software, PreForm, automatically suggests optimal orientation, supports, and layout, with the ability to manually refine as needed.

Continuously evolving:

Formlabs believe the best products grow better over time, and they arecommitted to continually evolving our hardware through software improvements.

Formlabs Form Cure

The Formlabs Form Cure is an all-new, state-of-the-art UV curing station that’s been specifically designed and engineered for Form 2 and Form 3 3D printed parts.

Providing a reliable and professional post-curing solution, the Form Cure has a heated chamber up to 80 °C and bathes parts in 405 nm UV light. 13 multi-directional UV LEDs and a rotating turntable ensure complete penetration, while a constant heart source bakes parts to achieve the most desirable finish for all engineering resins.

The Form Cure is exceptionally easy to use too. It has its own digital interface, with pre-programmed settings. The default setting is suitable for Standard Resins, and there’s also Recommended settings for specialist resins. Of course, the Form Cure also has a Quick Start guide, to help you make the most of it straight from the box.

Formlabs Form Wash

The Formlabs Form Wash is a state-of-the-art automated wash station that’s been engineered to clean parts printed with the Form 2 3D printer.

The Form Wash is built to fit the build platform of the Form 2 and Form 3 perfectly. You insert your part or parts into the Form Wash on the build platform (or standalone, if you prefer) and leave it to do its thing. The automated wash system has an impeller that agitates 90% Isopropyl Alcohol (IPA) around parts, to clean them completely.

With its automated wash cycle, the Form Wash eliminates the need for manual washing and related post-processing. It saves you time and effort. The tank holds 8.6-litres of IPA, which is enough to clean the largest parts and up to 70 prints. Included in the box is a hydrometer, which is used to routinely test the IPA so you know when it needs changing.

Compared to manual washing, the Form Wash is seriously efficient. It times washes perfectly to eliminate the risk of warping which can occur if parts are submerged in IPA for too long, and there’s even a siphon which lets you quickly transfer IPA to a wash bucket.

Formlabs Fuse 1+ 30W 3D Printer

Designed for maximum output and minimum waste, Fuse 1+ 30W is our compact SLS 3D printer that packs an industrial punch. Unlock unprecedented print speeds and a full range of materials to deliver truly rapid prototyping and production in-house.

Building on effective powder containment and an easy setup, Fuse 1+ 30W is equipped with a powerful, 30W laser enabling same-day delivery of prototypes and end-use parts. Active powder handling unlocks the use of exclusive, new materials such as carbon fiber-reinforced nylon, and a nitrogen purge print option allows for unprecedented performance and consistency across all SLS parts.

Whether you need a functional prototype today or produce hundreds of end-use parts each week, the Fuse 1+ 30W levels up your workflow for better consistency, shorter turnaround time, and higher efficiency.

Formlabs Form 3+ Basic Package

The Form 3+ turns liquid resin into flawless parts with Low Force Stereolithography (LFS)™ which consistently delivers presentation ready parts with unbelievable surface finish. This advanced print process offers incredible print quality, surface detail, and a platform for more advanced materials and applications. The Form 3+ offers users rapid print speeds, industry-leading accuracy and reliability, plus a wide range of materials. After printing, detach supports in seconds with Formlabs enhanced Light Touch Support structures that save post-processing time.

Each Form 3+ Low Force Stereolithography (LFS)™ 3D printer package includes a one-year warranty and the essential tools required to start printing: 3D printer, build platform, resin tank and finishing kit.

Select the Form 3+ Complete Package to also include the Form Wash and Form Cure for automation of post-processing to improve your workflow.

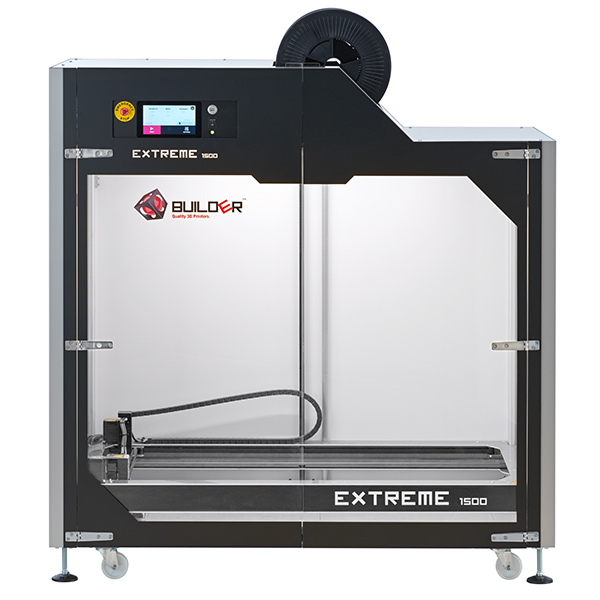

Builder Extreme 1500 PRO

The Builder Extreme 1500 PRO is a tall, narrow and very wide 3D printer which is perfect for architects, yacht builders and those in the automotive industry. Thanks to its slim shape, and wheels, the Extreme 1500 PRO can be easily moved between rooms.

New for 2019, the PRO model comes with a 7” touchscreen display. This makes controlling prints from the printer simple. It lets you control nozzle temperature, print bed temperature and the light in the build chamber. You can even watch instruction videos on it, just in case you need a refresher about certain features.

With its 1100 x 500 x 820 mm (XYZ) build volume and fully enclosed chamber, the Builder Extreme 1500 PRO offers the perfect environment for manufacturing long prototypes and models as one piece. Forget snap-fit models and gluing smaller parts together; print models in one go with killer accuracy and speed.

The fully enclosed build chamber provides a stable environment for the extrusion and layering process, while a unique dual-feed extruder system allows you to print support and primary material at the same time.

Builder Extreme 3000 PRO

The Extreme 3000 PRO is made to deliver 24/7. With the extremely large build volume of 1100x1100x820 mm XYZ it is the perfect fit for industrial applications. With large format 3D printing you have full design freedom and are able to print large parts in one piece.

The frame has been designed in a way that you have easy access to the build plate from both sides by removing the side panels. 3 different nozzles diameters, 0.4, 0.8 and 1.2 mm, are included to optimise print quality and time for your specific needs. The machine is fully equipped with features such as a heated bed, filament detection, a battery pack and auto bed levelling.

Easy access

The Extreme 3000 PRO has been designed to print extremely large parts, but you also need to be able to remove the printed parts easily. That is why the machine has removable panels on the left and right side. By removing the panels, you have easy access to remove prints or do any maintenance to the machine if needed.

Extremely large build volume

The Extreme 3000 PRO has an extremely large build volume of 1100x1100x820 mm XYZ. This allows you to print full size prototypes, parts, statues in one piece. The build volume of just under 1 m3 is the perfect size for 3D printing industrial applications.

Lynxter S300X

A compact, reliable and robust industrial silicone 3D printer with integrated support printing technology for unlimited shape design. The S300X is the ideal machine for producing customized masking parts for post-processing (painting, sanding, plasma treatment etc.), dampers, seals, orthoses certified for skin-contact and textiles with additional functionality.

The S300X combines robustness, precision and industrial efficiency in a compact size that fits in any workspace.

The large capacity cartridges allow the silicone printing of large parts or several small ones in complete autonomy, reducing the need for intervention. Its filtered, heated and silent chamber ensures the safety and comfort of its user.

The S300X can print a variety of materials including medical grade RTV2 silicone (5, 10, 25, 40 ShA) certified ISO 10993-05 for contact with skin, industrial grade RTV2 silicone (45shA) and polyurethane (from 50 to 85 ShA). These age-resistant silicones require no heavy post-processing and possess mechanical properties equivalent to those of injection molding.

Lynxter S600D 3D Printer

The Lynxter S600D is a one-of-a-kind 3D printer made for Industry 4.0

Enabling printing with an infinite range silicones, thermoplastics and ceramics means finding the right material for your application with the Lynxter S600D is easy.

It’s quick-change toolhead technology allows you to set up and print with the toolhead and nozzles of your choice in a matter of just minutes. For a new print project in a different material, simply change the toolhead!

Bambu Lab X1E Combo

The X1E now boasts enhanced connectivity options, including a newly integrated Ethernet port, ideal for establishing robust network connections in demanding scenarios. This Ethernet connectivity proves invaluable in areas with congested wireless signals. Furthermore, the X1E offers advanced network security with WPA2-Enterprise Wi-Fi Authentication methods (EAP-PEAP/EAP-TLS/TAP-TTLS) and the convenience of dedicated physical kill switches for both Wi-Fi and Ethernet, ensuring compliance with stringent network security requirements.

Bambu Lab P1S Combo 3D Printer

The Bambu Lab P1S Combo comes with the AMS - Automatic Material System. Unlock the incredible potential of multi-colour printing with the AMS combo. By acquiring the AMS units, you can harness the power of printing with multiple colours. With the option to stack up to 4 AMS units, you can achieve a stunning palette of up to 16 colours

You can get exceptional performance from the moment you open the box. Bambu Lab printer effortlessly operates without any tinkering required. Simply press the print button, and watch as the P1S takes care of all necessary calibrations, including Auto-Bed Leveling and Vibration Compensation. Enjoy hassle-free printing every single time.

Experience the perfect balance of speed and quality in your prints. Bambu Lab state-of-the-art control algorithm, enhanced by vibration compensation and pressure advance technology, enables lightning-fast printing while maintaining exceptional print quality and smoothness.

Experience superior control over filament extrusion and retraction with the P1 series' direct-drive extruder design. By directly connecting the motor to the extruder, you can get precise and consistent control, especially when handling flexible filaments. This advanced design guarantees smooth and blur-free prints by delivering accurate extrusion throughout the printing process

Bambu Lab P1S 3D Printer

You can get exceptional performance from the moment you open the box. Bambu Lab printer effortlessly operates without any tinkering required. Simply press the print button, and watch as the P1S takes care of all necessary calibrations, including Auto-Bed Leveling and Vibration Compensation. Enjoy hassle-free printing every single time.

Experience the perfect balance of speed and quality in your prints. Bambu Lab's state-of-the-art control algorithm, enhanced by vibration compensation and pressure advance technology, enables lightning-fast printing while maintaining exceptional print quality and smoothness.

Experience superior control over filament extrusion and retraction with the P1 series' direct-drive extruder design. By directly connecting the motor to the extruder, you can get precise and consistent control, especially when handling flexible filaments. This advanced design guarantees smooth and blur-free prints by delivering accurate extrusion throughout the printing process

Bambu Lab X1-Carbon Combo 3D Printer

The Bambu Lab X1 Carbon Combo- X1CC. This exceptional package combines the cutting-edge X1 Carbon 3D printer with the highly advanced Automated Material System (AMS). With enhanced cooling capabilities, a hardened nozzle, and a carburized impeller, the X1 Carbon Combo pushes the boundaries of material versatility. It opens up a vast selection of materials, including PA, PC, PET, and TPU, while specialising in carbon fibre and glass fibre-reinforced polymers. From robust prototypes to intricate designs, the X1 Carbon Combo empowers you to bring your ideas to life.

With the Bambu Lab Automatic Material System (AMS), you can now unleash your creativity by freely printing in multiple colours and materials Each AMS comes with 4 reusable spools - 1 high-temperature and 3 low-temperature spools., providing a diverse palette for your designs. Should you desire even more colour options, additional AMS units are available for purchase, allowing you to expand your creative possibilities.

Bambu Lab X1-Carbon 3D Printer

ntroducing the Bambu Lab X1 Carbon, a remarkable 3D printer designed to unleash the full potential of advanced materials. Equipped with enhanced cooling capabilities, a hardened nozzle, and a carburized drive gear, this printer opens up a vast array of material options, including PA, PC, PET, TPU, as well as specializing in carbon fiber and glass fiber reinforced polymers. With the X1 Carbon, your projects can reach new heights of strength and durability.

Bambu Lab P1P

The P1P, a cutting-edge device that has the tried-and-tested kinematics and motion control system of the Bambu Lab X1 series. Having an array of advanced sensors, this remarkable printer guarantees unwavering reliability throughout its operations. One of its standout features is its ability to seamlessly integrate with the automatic material system (AMS), enabling users to achieve captivating multi-colour prints effortlessly.

Whether you're a novice, a seasoned professional, or simply someone who revels in the joy of creativity, the P1P is perfectly tailored to meet your needs. This printer can be set up and ready to go in a matter of minutes. Additionally, it offers a host of mod-friendly features, allowing enthusiasts to upgrade and customize the hardware according to their preferences, making it their one-of-a-kind printer.

ADVANCED GRINDING SOLUTIONS LTD

Stand: 20-418

ADVANCED GRINDING SOLUTIONS LTD

Description

Advanced Grinding Solutions is leading the way in delivering cutting-edge grinding and finishing technology to the UK and Ireland's engineering sector. Our selection of high precision machinery, sourced from Europe's top manufacturers, showcases the latest innovations in machine tool design and process development.

Categories

Address

Unit 80 Hotchkiss WayBinley Industrial Estate

Coventry

West Midlands

CV3 2RL United Kingdom

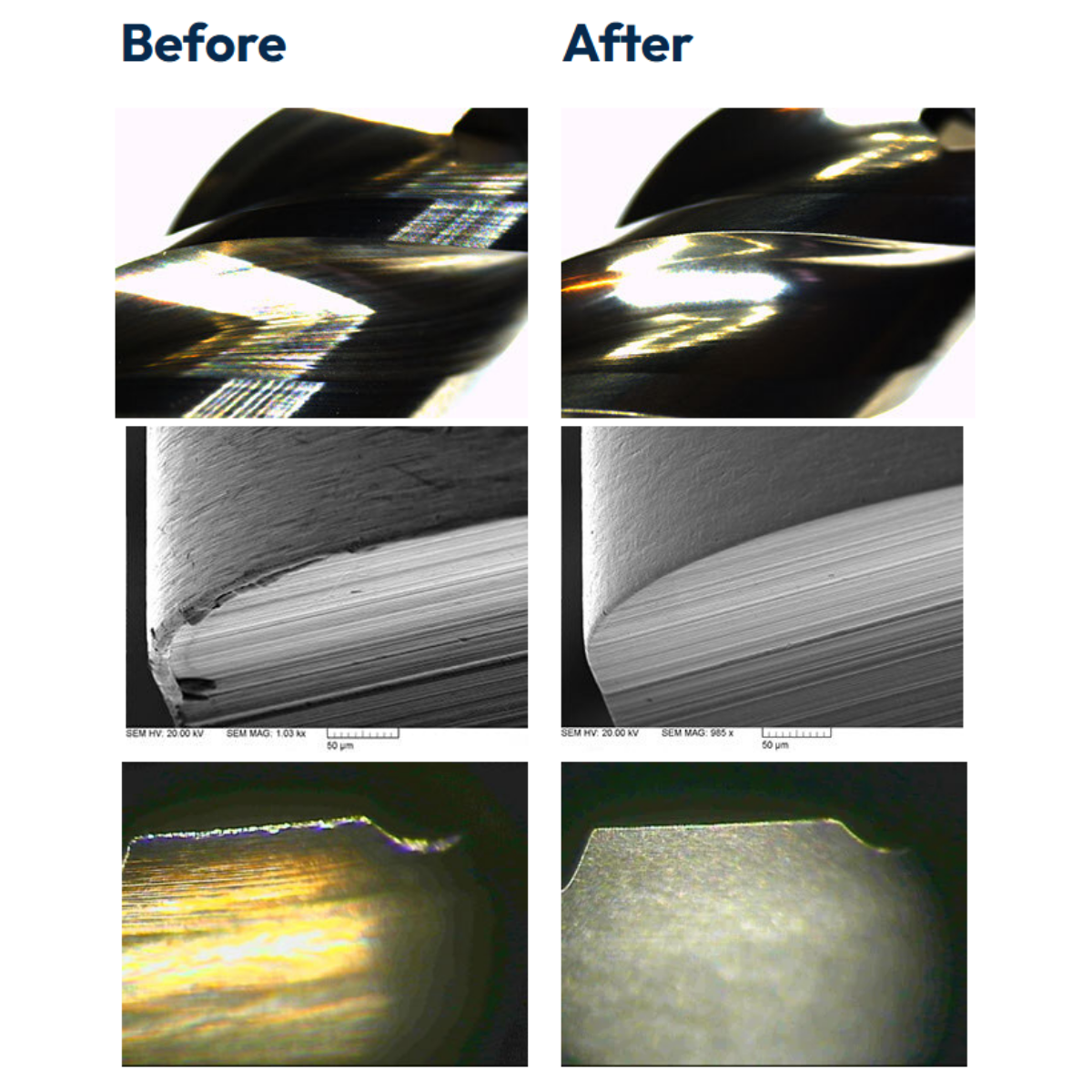

Magnetfinish Precision Edge Honing & Polishing

Magnetfinish is a remarkable and unique process that was originally developed to dramatically increase the performance and lifetime of all types of cutting tools. Generally, cutting tools that have been Magnetfinished can last over twice as long and be run at much higher speeds and feeds.

How It Works

Magnetfinish uses magnetically guided abrasive powder to polish cutting tools to a surface roughness as low as 0.02 μm Ra. It precisely rounds tip and flute edges to between 3–50 μm, improving consistency and tool geometry. This process enhances chip flow, extends tool life by removing the run-in phase, and improves coating adhesion by preparing surfaces prior to coating.

Applications

Ideal for taps, drills, end mills, reamers, and stamping tools, Magnetfinish is also used on automotive components and precision parts. It delivers burr-free finishes and consistent edge rounding on both coated and uncoated tools, boosting performance and durability.

Wick AG Custom Automation Solutions

Wick AG, headquartered in Küssnacht am Rigi, Switzerland, is a prominent member of the JAG Group, specialising in industrial automation, robotics solutions, and special-purpose machinery. Established in 1984, Wick AG has developed a strong reputation for designing and producing customised robot cells tailored to diverse industrial applications.

Wick AG excels in creating tailor-made automation solutions, including: automation systems integrating multiple processes; line production automation with extended autonomy; part tracking and specialised operator software; and automation integrated with overarching control systems. Processes such as checking and measuring, washing, drying, laser marking, deburring and assembly can all be included within a turn-key automated solution. These solutions are often based on Wick AG's standard products, adapted to meet specific customer requirements and are utilised in sectors such as:

Machine and automotive supply industries

Pharmaceutical and food industries

Medical technology and microtechnology

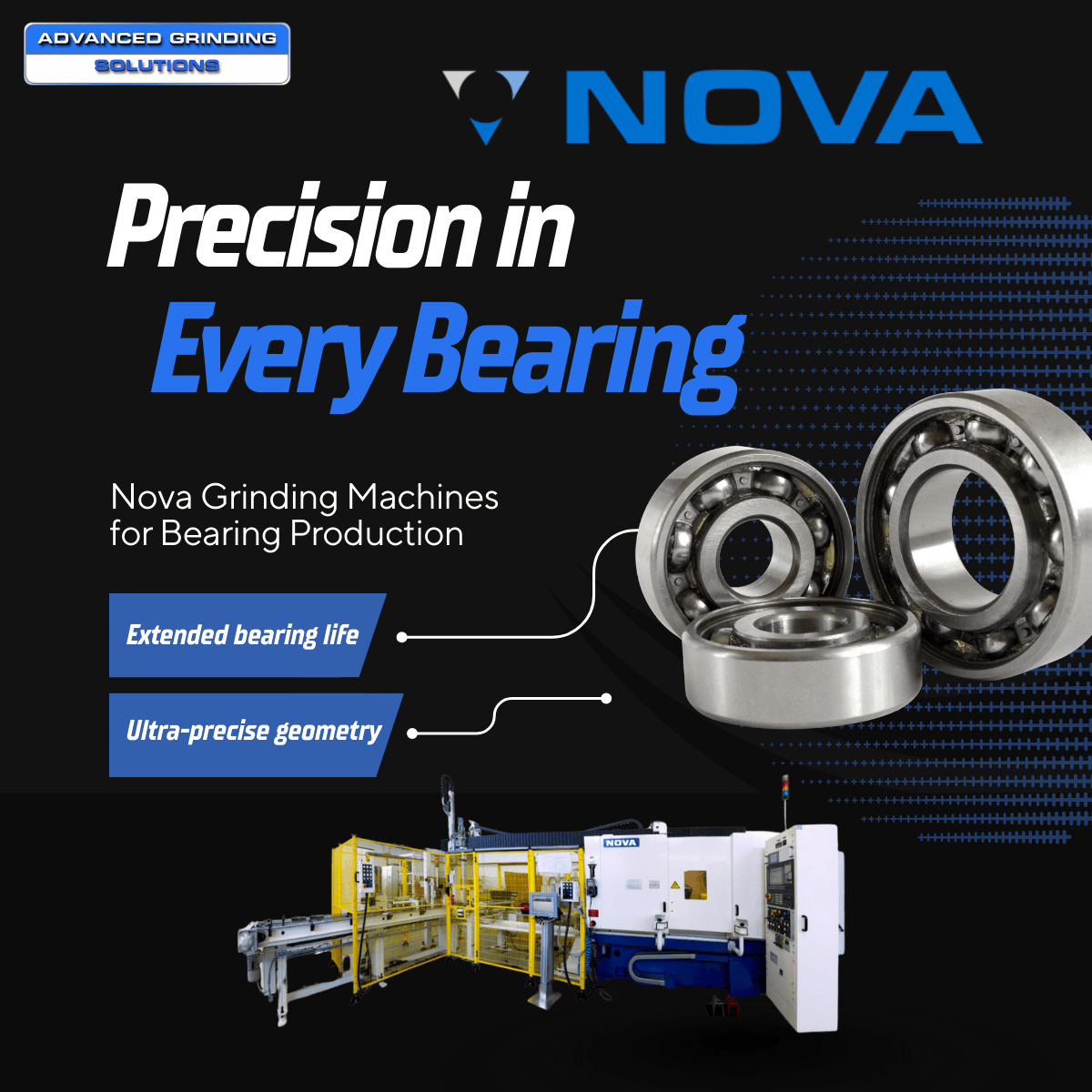

Nova Bearing Track Grinding Machines

Nova is a leading manufacturer of high-performance CNC grinding machines, specialising in internal, external, and combined grinding applications, with a particular focus on the bearing industry. Their machines are renowned for precision, speed, and uptime, featuring easy access for quick changeovers and maintenance. Flexible workholding options, including roller/shoe, magnetic/shoe, and chucking systems, accommodate a wide range of part geometries and materials.

The Nova PGE series external grinders achieve exceptional accuracy, delivering roundness below 0.0005 mm with ultra-fast cycle times. These machines are ideal for grinding roller bearing tracks, ball grooves, and CV joint cages. For components requiring multiple surfaces ground with strict tolerances, combination machines equipped with multi-spindle turrets enable internal, face, and external grinding in a single setup, enhancing efficiency and consistency.

Nova also specialises in machines for grinding key CV joint components for automotive and off-highway applications, including the outer race (internal spheres and ball tracks), inner race (external and ball tracks), and ball cage (internal, external, and windows).

Gerber Advanced Deburring Machines

Gerber has led the way in brush honing and polishing of ultra-hard materials for over 70 years. Their BP-M machines use specialised brushes: nylon for basic parts or natural fibres with diamond paste for complex shapes to polish surfaces and create consistent edge radii. Gerber use planetary polishing tables to deburr, polish, and edge-round components on one or both sides with exceptional precision.

A core application is polishing cutting tool inserts, with UK users and global customers like Sandvik, Kennametal, Iscar, and P. Horn. These machines form full-radius, waterfall, or flat-edge profiles while polishing surfaces in a single pass; with bench-top models capable of finishing over 250 inserts per hour.

Gerber systems process hard materials like CBN, PCD, sapphire, ceramics, and carbide, as well as softer metals like aluminium and brass. Applications range from cutting tools, valve plates, and pump parts to medical components like bone plates and screws, ensuring burr-free surfaces and controlled edge finishing.

Precision Diamond Dressing Rolls

We supply high-performance diamond dressing rolls for all types of grinding machines, ensuring optimal wheel conditioning, precision, and efficiency. Used across aerospace, automotive, and precision engineering, our rotary diamond dressers deliver cost-effective, high-accuracy solutions. Our range includes:

Handset Sintered Rolls – Durable and robust for general applications.

Random Set Sintered Rolls – Quick delivery with fine surface finish capabilities.

Reverse Plated Rolls – Ultra-precise for complex profiles and high-tolerance grinding.

Customised solutions for your dressing processes at competitive prices with design services and fast delivery.

DLyte Dry Electropolishing Systems By GPAInnova

DLyte machines use a patented dry electropolishing process - an innovative, non-abrasive technology that finishes metal parts without using liquid electrolytes. In a single automated step, DLyte can polish and deburr steel, stainless steel, cobalt chrome, titanium, aluminium, nickel, and precious metals. Surface finishes below 0.09μm Ra are achieved with zero impact on part geometry.

Ideal for components such as bone screws, implants, turbine blades, and cutting tools, DLyte provides a flawless, scratch-free finish, even on complex geometries, and without the micro-marks left by traditional polishing methods.

Available in sizes to suit everything from small-batch to high-volume production, DLyte systems are trusted across the medical, dental, aerospace, and automotive industries. Certified for biocompatibility, they offer a cleaner, more consistent, and scalable alternative to mechanical or abrasive-based polishing.

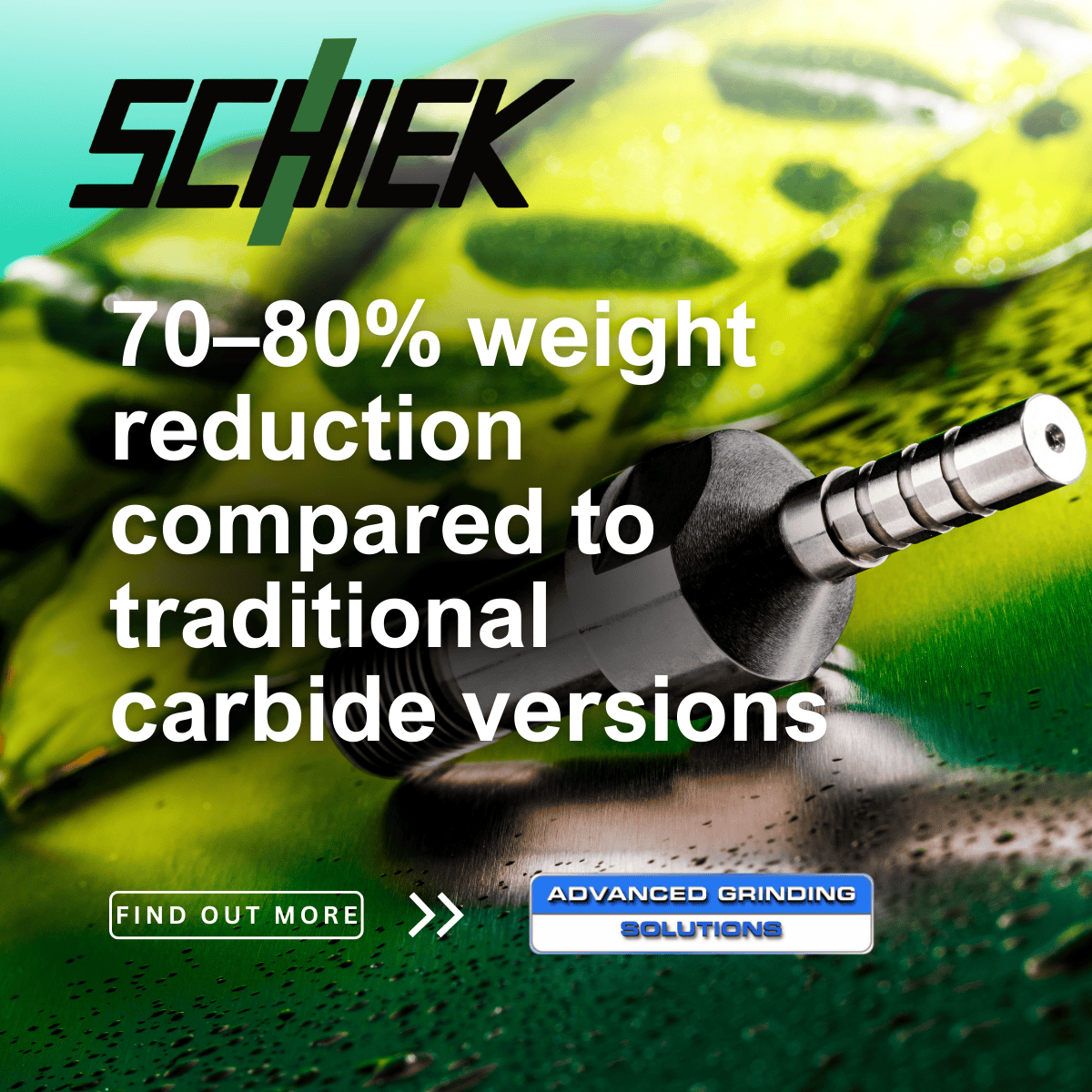

Schiek Grinding Arbors and Spindles

SCHIEK offers a comprehensive range of high-precision grinding arbors and spindles, including innovative GC and CB alloy options that are up to 80% lighter than traditional carbide versions, enhancing efficiency and reducing spindle wear. Their product lineup also encompasses custom-manufactured special parts tailored to meet specific industry standards.

Founded in 1987 by Hermann Schiek, SCHIEK Präzisions-Rundschleifen has evolved from a modest workshop into a leading manufacturer of high-precision grinding tools and components. Now in its third generation under Raphael Schurr, the company seamlessly blends traditional craftsmanship with cutting-edge technology to deliver exceptional quality and innovation. For more than 35 years, SCHIEK's core values have remained the same: ultimate precision, reliability, and a commitment to providing customers with customised solutions to ensure the success of their projects.

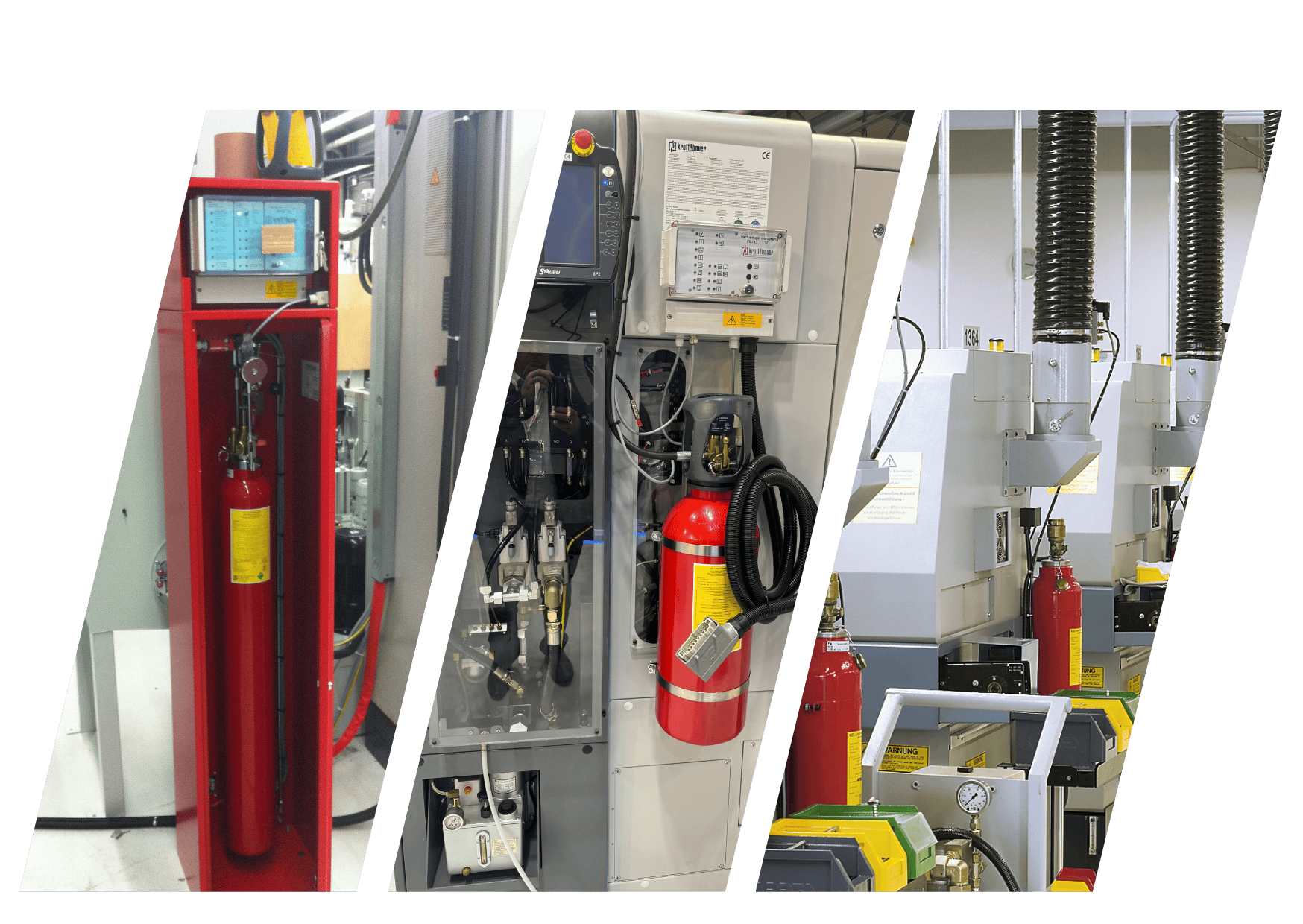

Kraft & Bauer Fire Suppression Systems

Kraft and Bauer UK specialise in advanced fire suppression systems engineered specifically for machine tools. Since 2007, they have provided tailored fire protection solutions for everything from CNC grinding machines and EDM systems to laser systems, meeting the strictest safety and insurance standards. With over 17,000 installations worldwide, their technology is trusted by leading machine manufacturers and engineering companies to protect valuable assets, ensure operator safety, and maintain operational continuity. Their microprocessor control systems with advanced optical sensors can suppress fires in as little as two seconds, preventing machine damage before it happens.

Danobat Grinding Machines

Founded in 1954, Danobat has grown into a leading global manufacturer of ultra-high-precision grinding machines. Their extensive range includes horizontal and vertical grinders for internal, external, unround profile, and radii grinding.

Danobat leads the industry with cutting-edge technology, sub-micron precision, and multi-spindle capabilities. With over 750 employees worldwide, the company operates manufacturing plants in Spain, Germany, and the Netherlands, alongside tech centres in Europe, the USA, and China.

Danobat machines serve aerospace, automotive, energy, medical, and railway industries, handling complex applications such as aero-engine components, automotive parts, hydraulic systems, and much more. Danobat also provides expert local support and service based here in the UK.

FLP Fine Grinding & Lapping Machines

The broad range of FLP fine grinding and lapping machines includes for both twin wheel - double sided CNC Lapping Machines and also single sided Lapping machines. The size of machines ranges from the most basic of 400mm in diameter having three working stations up to the world’s largest 100 ton 4-meter diameter monsters.

FLP also offers used machines, often from stock, that have been rebuilt to an as-new standard as well as supplying replacement spare and wear parts for all Lapping and fine grinding machines of every make or model. Regardless of the type and size of a customer’s old fine grinding, flat honing, lapping or polishing machine – FLP will carry out process and technology orientated improvements and general overhauls of your machines for you.

Tschudin Centerless Grinding Machines

Tschudin – One of the greatest names in grinding – continues to explore new advances in centerless grinding technology. The Tschudin machines benefit from several patented features that give them major advantages over any other machines in their class and today the Tschudin Cube machine is stated as being the world’s easiest, simplest and fastest CNC centerless grinder to set-up.

A unique feature on all Tschudin machines is also the patented movable workrest axis (W-Axis) which allows for additional grinding processes such as the highly efficient multi part grinding of several parts at a time or to split up grinding processes in the same grinding cycle to have both a rough and also a finish grind operation in one automatic set-up. Thanks to the W-axis, the loading and unloading of the workpieces is always outside of the grinding zone, allowing simplified and safe automation or safe manual loading. This feature is highly attractive for those looking to meet health and safety obligations because otherwise the hand loading of parts to centerless grinding machines can be very dangerous.

Krebs & Riedel Grinding Wheels

Krebs & Riedel who were founded in 1895 have been manufacturing high quality conventional, diamond and CBN abrasives for well over 100 years and we are able to count leading UK engineering companies such as Perkins Engines, Grundfos and Delphi Diesel Systems amongst our ever growing customer base. Krebs & Riedel who employ approx. 250 people and have a turnover of around £35m are constantly introducing new types of wheels with improved grain structures and novel bonding systems that enhance grinding wheel quality and optimise performance.

Diamond and CBN wheels that have been manufactured by Krebs & Riedel for more than 20 years are available from 3mm to over 900mm in diameter with peripheral grinding speeds of up to 160 m/s. We are also supplying UK customers many small diameter CBN wheels for jig grinding applications. These special CBN wheels are supplied in a variety of sizes, usually from 5 – 35mm in diameter in small batch sizes as low as 3 off. These can be supplied unmounted or pre-mounted onto high precision jig grinding mandrels as specified by the end user.

Comat Super Filtration Systems

COMAT is a specialist manufacturer of high-quality filtration systems for the management of metal working cutting oil across the engineering industry.

Through an in-depth analysis of each individual client's needs, Comat designs and manufacture super-filtration systems that deliver ≤ 2-3 μm filtration quality throughout the entire working cycle thus maximising the quality of parts produced on machine tools whilst minimising lifetime running costs and maintaining maximum coolant consistency..

Comat systems can be customised to meet specific client's needs allowing for maximum efficiency of the filtration process. Oil is filtered to a better quality than new unused oil on Comat systems.

The remote monitoring of the performance of their filtration systems from their HQ near Milan in Italy ensures effective after sales support. Systems can be monitored in real-time during manufacturing processes and customers filter systems fine-tuned by Comat to ensure that the optimum filtration quality is obtained at all times.

Today, more than 20,000 machine-tools use Comat Filtration Systems, with more than 20,000,000 litres of metal working oil super-filtered every single day. Comat operates globally and have a 30-year history in developing the most advanced filtration systems that are available.

Comat's Superfiltration Technology uses continuously regenerating filtering media (diatomaceous earth, cellulose or other vegetable media), to ensure that particles larger than ≤ 3 μm are removed from cutting fluids and the fluid is maintained at a stable desired fixed temperature. Oil that is filtered by Comat systems does not need to be replaced and many clients report that they have never changed the oil for up to 20 years (save top-ups due to oil loss).

AGS General Brochure

DownloadENERGAS

Stand: 19-419

ENERGAS

Description

Energas is a key part of the Air Liquide Group’s UK presence. Energas is a leading service provider of cylinder gases and associated equipment including safety, and consumables to a variety of UK industry sectors, delivering a local and personal service, combined with global quality products and expert technical support.

Categories

Address

Station RoadColeshill

Birmingham

West Midlands

B46 1JY GB

Welding Cobot

Collaborative robot welding, also known as cobot welding in short, provides a great solution for companies of all sizes to increase their productivity and improve quality. Cobot welding combines human skills with robotic welding precision to create a collaborative and productive work environment. The new modern technology can help transform your business and allow you to work in a smarter way.

A CoWelder will offer a great return on investment through improved efficiency, productivity, and safety.

Esab Rogue Emp 210 Pro Multi Process Welding Machine

ESAB Multi-process Welders Rogue EMP 210 PRO is an inverter-based multi-process welding system designed to address all your welding project needs, from light fabrication to repair and maintenance. The system features industrial-grade arc performance and full-featured controls that allow the welder to fine-tune arc characteristics based on the material they are welding.

With a weight of only 16.7 kg, 230V single-phase input, and compatibility with 10 kVA generators, this system provides maximum flexibility and portability, both in the shop and in the field.

Shaver Rolltect Retractable Welding Screen

The Retractable Weld Screens redefine welding safety and convenience. Offering efficient mobility, these screens can be swiftly moved to wherever welding is needed. Whether they are fixed or portable, these screens use tension from a roller base to keep the guard securely in place. Operators can effortlessly walk the guard from the base mount roller to latches on the opposite side of the work cell. When it’s time to accommodate products in or out of the work cell, the guard can be unlatched and returned to the roller base.