You cannot change the laws of physics – but Excetek’s efficiency can take you further

With the snowballing costs of energy currently affecting UK homes and businesses the high efficiency, and thereby reduced energy consumption, of manufacturing equipment has never been more important. For decades, EDM machine tool specialist Excetek has focused its innovation and development on addressing these challenges. From its generators designed to work at peak effectiveness to the ability of the machines to operate for long periods unattended, overnight on lower tariff electricity, Excetek machine tools provide ‘more miles per gallon’.

Electro-discharge machining (EDM) is an unconventional machining process that can remove, or machine, electrically conductive materials by using thermal energy (melting and partial vaporisation of the workpiece) that is generated by a series of sparks occurring between the electrode and workpiece. The EDM process is often applied to parts made from harder materials in complex shapes, where characteristics such as strength, temperature–resistance, fine surface finish, and accurate dimensions are required.

While the process of machining using EDM is governed by the laws of physics, what does differ from one EDM machine tool to the next is the generator technology and the control circuits required to accurately apply the spark. “Excetek has invested considerable resources in both the generator that creates the spark required and the control circuits that ensure it is applied in the most efficient way to the workpiece,” states Ian Holbeche, Managing Director of the exclusive UK and Eire agents for Excetek wire cut, die sinking and hole drilling EDM machines.

He continues: “Excetek’s Embedded Power System uses Digital Power Management (DPM) technology extensively. Within the Stable Discharge Module, it ensures any fluctuations of the incoming power supply do not affect the quality or speed of the EDM process, so any spikes or troughs are smoothed out and a stable, controlled spark is generated at the workpiece interface.”

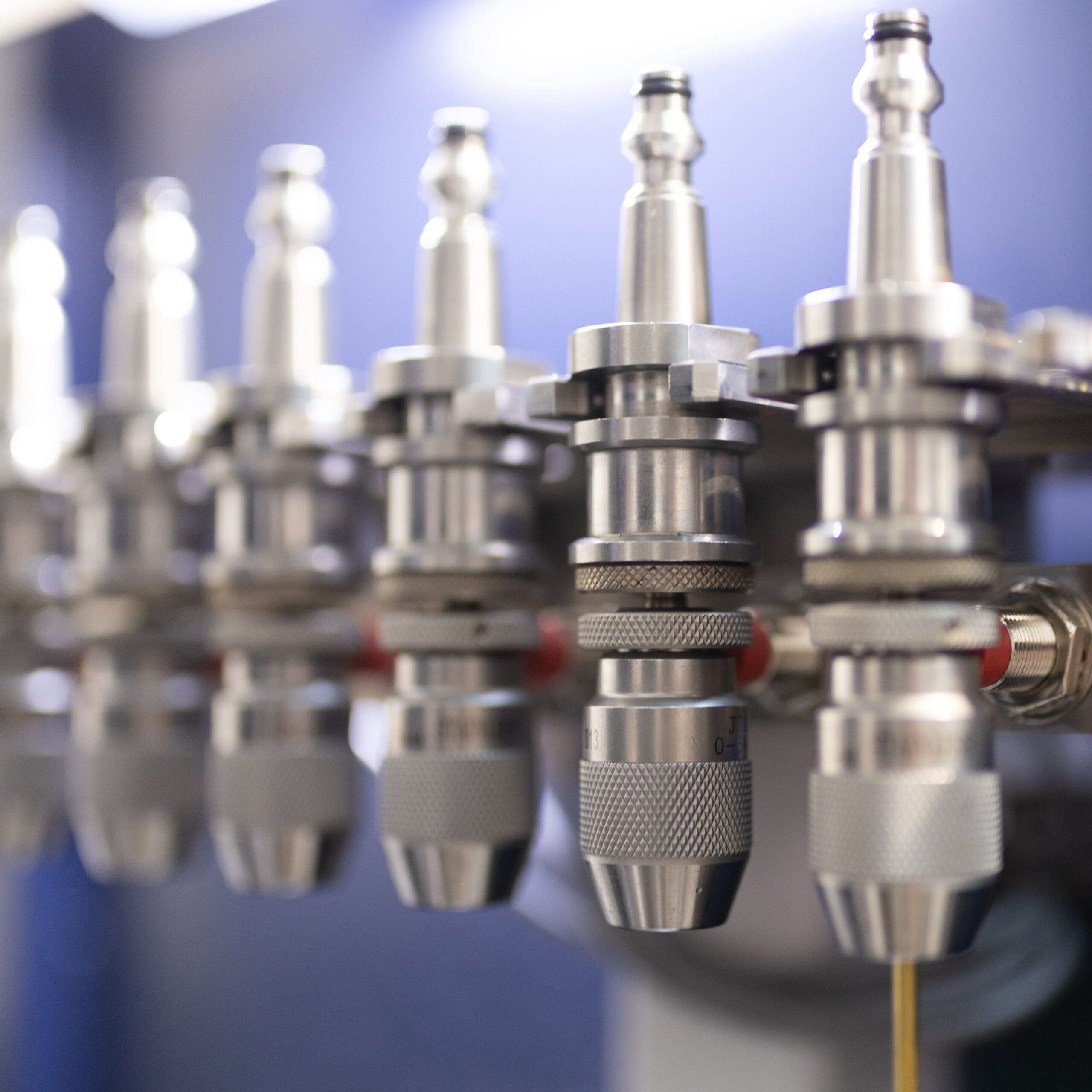

Spark occurs between the workpiece and the closest points of the electrode, which may be a solid form for die sinking, a highly conductive wire for wire cutting or a small diameter rod for hole drilling. The material is removed from both the electrode and workpiece by the spark, creating an increase of the distance between the electrode and the workpiece at that point. This causes the next spark to occur at the next-closest points between the electrode and workpiece. Even though the surfaces have only very minute peaks and valleys, these very small changes of dimension allow the EDM spark to occur between the closest points.

The EDM process has a reputation for creating exceptional surface finishes, and the latest Excetek Gplus range of CNC wire EDM machines enhances this even further with a standard machining surface roughness of Ra 0.3 micron and a Super Finish Circuit able to reduce this further to Ra 0.14 micron. Ian Holbeche says: “The gains here are achieved by possibly removing the need for any super-finishing operations, such as grinding, lapping or honing, to obtain the surface characteristics required for the finished part.”

The embedded power design allows for real-time feedback of the discharge cutting status, stabilising the process, and improving cutting speeds and accuracy. It supports further performance benefits such as corner break prevention, intelligent corner control and highspeed working.

“In terms of speed and reliability we know Excetek’s Automatic Wire Threading system, that re-feeds the wire at the point of breaking, is one of the best available and it supports unmanned running of the machine tools. However, it is still more efficient to avoid a wire break and the Real Time Sparking control provides quick response feedback that allows cutting conditions to be adjusted to improve efficiency. We know we can increase corner cutting speeds by 35% and still reduce the chance of wire breakage by 90% thanks to the levels of digital control available,” states Ian Holbeche.

It is not just corners that can be cut quicker using Excetek’s digitally controller discharge technology. With the digital signal used to detect the discharge density, the CNC control system can calculate the discharge area according to the capacity available and it applies the correct discharge energy, wire tension and water flow to improve speed and accuracy. Typically, the cutting time can be reduced by 30 to 40%. The latest technology development for the primary source of day was a field work

The water, or dielectric fluid, flow is important in the EDM process as the spark from the electricity between the electrode and workpiece introduces heat. The main characteristic of the dielectric fluid is that it works as an electrical insulator, until enough voltage is applied to cause it to change into an electrical conductor. The dielectric fluid deionises when the spark is turned off and the fluid returns to being an electrical insulator.

Also, a small amount of the electrode and workpiece material is vaporised with each spark. This material remains in the sparking gap between the workpiece and the electrode in the form of a cloud. Often called an EDM chip, this debris is made up of the electrode and workpiece material and it must be removed from the sparking area for efficient machining. This removal is performed by flowing dielectric fluid through the sparking gap. As standard, a high-precision water chiller maintains the dielectric temperature within a +/- 0.2 oC thermal band to ensure a stable cutting environment for the workpiece.

Ian Holbeche concludes: “Every manufacturing business must consider the true cost of ownership for any machine tool. Excetek has set out to minimise any running costs and offers a significant gain in overall efficiency. With the initial purchase price of the machine being at least 25% lower than a Japanese or Swiss equivalent sized machine, and exceptional levels of local application and aftersales service support, the arguments really stack up in favour of Excetek EDM technology from Warwick Machine Tools.”