Complete manufacturing of complex components: NILES-SIMMONS machine concept “CLOSED-DOOR-MACHINING“

NILES-SIMMONS developed the machining concept “CLOSED-DOOR-MACHINING” to meet the ever-increasing requirements concerning the manufacturing of complex, high-precision parts and components initially for the aviation industry.

This concept allows the complete machining of parts in one continuous process within one machine and without any operator interventions. It is applicable for various part types which, historically, had to be manufactured in several process steps on various different machines.

When using the “CLOSED-DOOR-MACHINIG”-concept, a raw part is clamped into the machine and after several fully-automatic re-clamping and re-chucking procedures, it can be removed as a completely finished part. The machining runs entirely uninterrupted and depending on the part complexity shifts can be overlapped a number of times throughout the cycle.

Since the process runs fully automated, the time associated with labor-intensive part-handling procedures moving parts between several machines is removed and lay down spaces can be reduced. Similarly, the tasks for operators are also reduced since less machines are required and less operator interventions are necessary.

By integrating all the necessary technology into one machine, such as turning, milling, drilling, deep-hole drilling, boring, bottle boring thread cutting, gear hobbing, power skiving and grinding, there is no need to use “process specific” single machines, which in the long term considerably contributes to much more cost-efficient production.

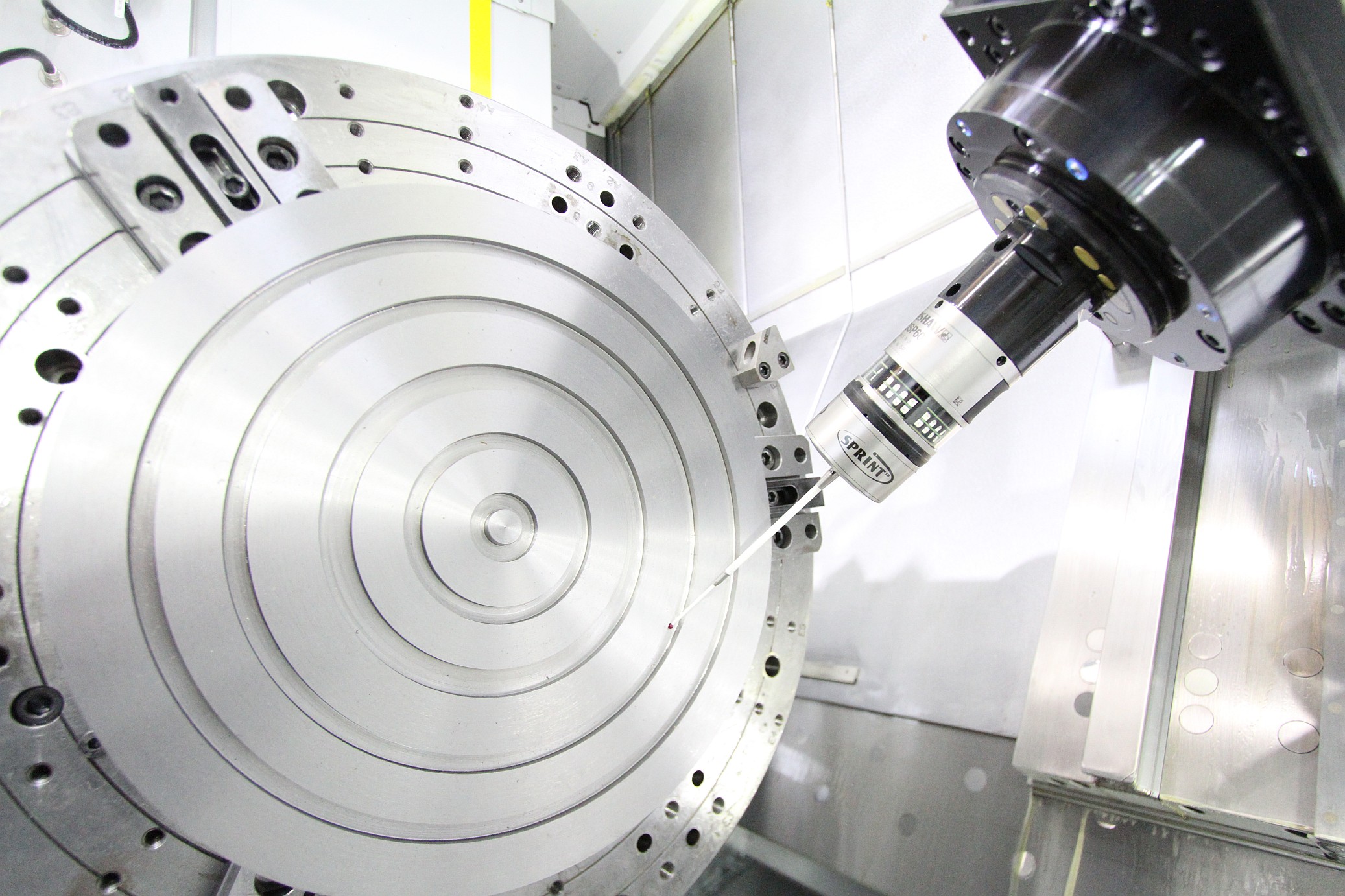

For the implementation of the concept we introduced several new machining and measuring technologies. In doing so it is now possible to achieve extraordinarily high accuracies of <5µm in a process-reliable way by the use of scanned part measuring through RENISHAW Sprint measuring sensor and automatic tool compensation after the measurement cut. As well as Sprint there are also other various touch measuring sensors such as RMP60 or RMP600 fitted to carry out other measurement tasks.

At the same time, the measurement of all necessary tools also takes place, again fully automated within the machine using a touch measuring system for fixed tools and an optic measuring system (laser) for rotationally symmetric tools.

In order to accommodate the large number of tools required to-be-used, it is possible to configure two tool magazines headstock and tailstock side with a capacity of up to 144 tools each to service the multi-axes turning-milling unit. The tools can be exchanged automatically into the working area from either side.

Alternatively, for specific machining tasks an additional magazine can be applied for the counter spindle or tailstock sided boring bar slide. This long tool magazine has a maximum of 16 positions for long tool cartridges. These long tools are also exchanged automatically into the second slide.

The long tools with up to two meters in length can be operated with high coolant-pressure of up to 300 bar and respectively with a high flow rate of up to 150 l/ min. Consequently, any deep-hole drilling requirement can be achieved as part of an extremely stable and reliable process. The temperature-controlled coolant can be programmed with both pressure- or volume-controlled and monitored via sensors.

For surface optimization of the parts, it is also possible to integrate grinding operations in the machine. The grinding wheel can be exchanged, measured and dressed fully automated. For sparking, there are also sensors available. The coolant, which needs to be positioned close to the process, is controlled and positioned by a separate, programmable NC-axis.

A highest equipped machine with turning-milling unit, boring bar slide, turret (bottom), main- and counter spindle as well as steady rests and tool change units can be configured with up to 32 NC-axes. Due to this complexity, a CAD/ CAM system with integrated post processor is essential.

Furthermore, a liquid-cooled special concrete machine bed is used to achieve higher temperature stability and to ensure the requested accuracies despite variation of temperature. The machining centers are also equipped with damping and vibration reducing components such as FEM optimized slide-geometry, hydraulic clamped components of the part-axes, damping surfaces in machining direction and roller guides of the machining axes in size 45/55.

To ensure a clear and easy operation it is used a Siemens OP 19 panel with additional touchscreen for process monitoring.

The process security within the “CLOSED-DOOR-MACHINING “-concept is significantly enhanced through NILES-SIMMONS comprehensive software modules driven by industry 4.0, such as Volumetric Compensation Software, spindle modulation, axis compensation, tool breakage- and drive monitoring.

The smooth interaction of these software components with the sophisticated machining- and measuring technologies and the resilient and well-conceived machine design builds the foundation for successful “CLOSED-DOOR-MACHINING “without operator intervention.

This efficient machining concept is successfully running at numerous customer facilities worldwide and has established in the market with great success.